304L Stainless Steel Powder in AM

Table of Contents

Additive manufacturing (AM), also known as 3D printing, has revolutionized the way we design and produce parts. This technology allows for the creation of complex geometries with incredible precision, opening doors for innovation across various industries. But what fuels this revolution? Enter metal powders – the building blocks of AM for metallic parts.

Among the many metal powders available, 304L stainless steel stands out as a popular choice for its versatility and excellent properties. This article delves into the world of 304L stainless steel powder for powder bed fusion (PBF) AM, exploring its applications, advantages, limitations, and specific metal powder models available.

Understanding 304L Stainless Steel Powder

304L stainless steel powder is a low-carbon variant of the widely used 304 stainless steel. The “L” designation indicates a lower carbon content (less than 0.03%) compared to standard 304 (up to 0.08%). This reduction in carbon minimizes carbide precipitation during the AM process, leading to improved weldability and corrosion resistance.

Here’s a breakdown of the key aspects of 304L stainless steel powder:

Composition:

| Element | Weight % |

|---|---|

| Iron (Fe) | Balance |

| Chromium (Cr) | 18-20 |

| Nickel (Ni) | 8-10.5 |

| Manganese (Mn) | 2 |

| Silicon (Si) | 1 |

| Carbon (C) | ≤ 0.03 |

Properties:

| Property | Value |

|---|---|

| Density | 7.9 g/cm³ |

| Melting Point | 1450°C (2642°F) |

| Tensile Strength | 570-750 MPa (82,000-109,000 psi) |

| Yield Strength | 205-310 MPa (30,000-45,000 psi) |

| Elongation | 30-50% |

| Corrosion Resistance | Excellent |

Benefits:

- Versatility: 304L stainless steel powder offers a good balance of strength, corrosion resistance, and formability, making it suitable for various applications.

- Excellent Corrosion Resistance: The high chromium content provides outstanding resistance to rust, pitting, and other forms of corrosion in many environments.

- Good Weldability: Due to the low carbon content, parts printed with 304L powder can be readily welded using traditional techniques.

- Biocompatible: The low nickel content makes 304L a good choice for some biomedical applications.

Limitations:

- Strength: Compared to higher-grade stainless steel powders, 304L offers moderate strength.

- High-Temperature Applications: While corrosion resistant, 304L may not be ideal for prolonged exposure to very high temperatures.

Applications of 304L Stainless Steel Powder in AM

The versatility of 304L stainless steel powder translates into a wide range of applications across various industries. Here are some prominent examples:

- Aerospace: Components for aircraft interiors, ducting, and non-critical structural parts can benefit from 304L’s lightweight nature and corrosion resistance.

- Automotive: Applications include brackets, housings, and trim pieces that require good strength and aesthetics.

- Medical Devices: Surgical instruments, prosthetics, and dental implants can be printed with 304L powder due to its biocompatibility and corrosion resistance.

- Chemical Processing: Parts exposed to mild chemicals can be manufactured with 304L powder due to its excellent corrosion resistance.

- Consumer Goods: Jewelry, watches, and other decorative items can be printed with 304L powder for its aesthetics and durability.

Advantages of 304L Stainless Steel Powder for AM:

- Design Freedom: AM allows for the creation of complex geometries not possible with traditional manufacturing, unlocking innovative designs in these applications.

- Lightweighting: Compared to traditional materials, 304L can contribute to weight reduction in some applications, which is crucial in industries like aerospace.

- Customization: AM enables the production of parts with specific features and functionalities tailored to individual needs.

- Reduced Waste: AM minimizes material waste compared to subtractive manufacturing techniques.

Disadvantages of 304L Stainless Steel Powder for AM:

- Cost: Metal powders can be more expensive than traditional materials, impacting production costs.

Metal Powder Models for 304L Stainless Steel

With a clearer understanding of 304L stainless steel powder and its applications, let’s delve into the world of specific metal powder models available for PBF AM. Here, we’ll explore ten popular options, highlighting their key features and potential advantages/disadvantages:

1. EOS Inox 316L (equivalent to 304L):

- Manufacturer: EOS GmbH

- Description: A gas-atomized 304L equivalent powder known for its excellent flowability and packing density, leading to good printability and surface quality. Certified to various aerospace standards (AMS 5644, BMS 4930K).

- Advantages: High consistency, reliable printability, good for aerospace applications.

- Disadvantages: May be slightly more expensive compared to some non-certified options.

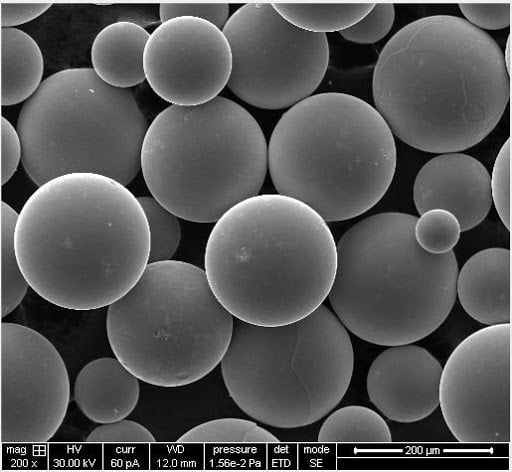

2. Höganäs AM 304L:

- Manufacturer: Höganäs AB

- Description: A gas-atomized 304L powder known for its spherical morphology and tight particle size distribution, promoting good flowability and laser absorption during printing.

- Advantages: Consistent quality, good printability, suitable for various applications.

- Disadvantages: Might require specific printing parameters for optimal results.

3. LPW 316L (equivalent to 304L):

- Manufacturer: LPW Technology Ltd

- Description: A gas-atomized 304L equivalent powder with a focus on high density and low oxygen content. This translates to improved mechanical properties in printed parts. Certified to aerospace standards (AMS 5644).

- Advantages: High density, good mechanical properties, ideal for demanding applications.

- Disadvantages: May require stricter printing environment control due to low oxygen content.

4. Carpenter Invar 304L:

- Manufacturer: Carpenter Additive Manufacturing

- Description: A gas-atomized 304L powder with a controlled chemistry for improved dimensional stability and reduced warping during printing. This makes it suitable for applications requiring precise tolerances.

- Advantages: Excellent dimensional stability, good for parts with tight tolerances.

- Disadvantages: May have a slightly higher price point compared to standard 304L options.

5. SLM Solutions Realizer 304L:

- Manufacturer: SLM Solutions GmbH

- Description: A gas-atomized 304L powder with a focus on high sphericity and narrow particle size distribution. This combination ensures good flowability and minimizes segregation during printing, leading to consistent part quality.

- Advantages: High sphericity, consistent part quality, good for various applications.

- Disadvantages: May require specific printer settings for optimal results based on the machine model.

6. Oerlikon AM SC316L (equivalent to 304L):

- Manufacturer: Oerlikon AM GmbH

- Description: A gas-atomized 304L equivalent powder with a focus on high purity and low inclusion content. This contributes to improved mechanical properties and corrosion resistance in printed parts.

- Advantages: High purity, good mechanical properties and corrosion resistance.

- Disadvantages: May be slightly more expensive compared to standard 304L options due to the focus on purity.

7. ExOne LaserForm 316L (equivalent to 304L):

- Manufacturer: ExOne GmbH

- Description: A gas-atomized 304L equivalent powder specifically developed for binder jetting AM. This powder offers good flowability and compatibility with binder materials used in this printing process.

- Advantages: Optimized for binder jetting AM, good flowability and compatibility with binders.

- Disadvantages: Not suitable for PBF AM applications due to its formulation for binder jetting.

8. AP&C AM 304L:

- Manufacturer: AP&C Additive Manufacturing

- Description: A gas-atomized 304L powder with a focus on cost-effectiveness. It offers good printability while maintaining a competitive price point.

- Advantages: Cost-effective option for general-purpose 304L printing.

- Disadvantages: May not have the same level of consistency or specific properties as some higher-priced options.

9.㎥Cubic AM 304L:

- Manufacturer: ㎥Cubic Printing International Inc.

- Description: A water-atomized 304L powder offering a cost-effective alternative to gas-atomized options.

FAQ

Q: How to choose the right 304L stainless steel powder for my application?

A: Consider these factors when choosing a 304L stainless steel powder:

- Application Requirements: The specific application will dictate the most important properties for the powder. For instance:

- High-precision parts: Prioritize dimensional stability (e.g., Carpenter Invar 304L).

- Parts exposed to harsh chemicals: Prioritize superior corrosion resistance (e.g., Oerlikon AM SC316L).

- Cost-sensitive applications: Explore cost-effective options (e.g., AP&C AM 304L) while ensuring it meets minimum requirements.

- Machine Compatibility: Different AM machines may have specific requirements for powder characteristics like particle size distribution and flowability. Ensure compatibility between the chosen powder and your printing equipment by consulting the machine manufacturer’s recommendations.

- Cost vs. Performance: There’s a trade-off between cost and performance. While some options prioritize affordability (e.g., AP&C AM 304L), others might offer superior consistency or specific properties at a higher price point (e.g., EOS Inox 316L).

Q: Where can I buy 304L stainless steel powder?

A: Several reputable suppliers offer 304L stainless steel powder for PBF AM. Here are some examples:

- Metal3DP (https://met3dp.com/)

- Höganäs AB (https://www.hoganas.com/en/)

- LPW Technology Ltd (https://www.carpenteradditive.com/news-events/lpw-technology-am-metal-powder-manufacturing)

- Carpenter Additive Manufacturing (https://www.carpenteradditive.com/)

- SLM Solutions GmbH (https://nikon-slm-solutions.com/)

- Oerlikon AM GmbH (https://www.oerlikon.com/am/en/)

- ExOne GmbH (https://www.exone.com/)

- AP&C Additive Manufacturing (https://cimp3d.org/new-large-am/)

- ㎥Cubic Printing International Inc. (https://www.ttc.com.tw/en-us/dirProduct/frmProduct6.aspx)

- Bassett Metals Inc. (https://www.bassettinc.com/metal-fabricating-and-assemblies/)

Q: What safety precautions should I take when handling 304L stainless steel powder?

A: Metal powders can be fine and pose inhalation hazards. When handling 304L stainless steel powder, it’s crucial to follow safety guidelines:

- Use a well-ventilated workspace: Minimize airborne powder by using a fume hood or ventilated enclosure during handling and printing.

- Wear appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and a respirator with a P-100 filter to prevent inhalation of powder particles.

- Practice good housekeeping: Clean up spills promptly and avoid creating dust clouds. Regularly clean work surfaces and equipment to minimize powder accumulation.

- Dispose of waste properly: Follow local regulations for disposal of metal powder waste.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731