New types in 3D Printing Equipment

Table of Contents

The world of 3D printing is constantly evolving, pushing the boundaries of what’s possible. Gone are the days of limited materials and clunky machines. Today, a new generation of 3D printing equipment is emerging, offering groundbreaking capabilities and ushering in a future of unparalleled creation. Whether you’re a seasoned professional designer or a curious hobbyist, these innovative machines have the potential to revolutionize your workflow and ignite your imagination.

This comprehensive guide dives deep into the exciting world of new 3D printing equipment. We’ll explore some of the most cutting-edge technologies, unpacking their functionalities, advantages, and potential applications. Buckle up, and get ready to be amazed!

Fiber Optic Digital Manufacturing (PμSL) 3D Printer

Imagine a 3D printer that uses light to solidify resin with pinpoint accuracy, creating objects with unparalleled detail and surface finish. That’s the magic of Fiber Optic Digital Manufacturing (PμSL) 3D printing. This innovative technology employs a high-resolution laser beam that travels through a network of fiber optic cables, directing light precisely onto a vat of photosensitive resin.

Advantages:

- Microscopic Precision: PμSL boasts the highest resolution currently available in 3D printing, capable of producing objects with features as small as a few microns. This makes it ideal for applications like microfluidics, micromechanics, and intricate jewelry design.

- Superior Surface Finish: The precise light manipulation in PμSL printing results in incredibly smooth and near-mirror-like surfaces, eliminating the need for extensive post-processing.

- Biocompatible Materials: Due to the light-curing process, PμSL printers can work with a wider range of biocompatible resins, opening doors for advancements in medical prototyping and bioprinting.

Disadvantages:

- Limited Build Volume: PμSL printers typically have a smaller build volume compared to other technologies, restricting the size of objects they can produce.

- Slower Printing Speeds: The high precision of PμSL printing comes at the cost of speed. Printing intricate objects can take significantly longer compared to other 3D printing methods.

- Higher Cost: The sophisticated technology behind PμSL printers often translates to a higher price tag compared to more conventional techniques.

Who Should Consider PμSL Printing?

This technology is perfect for those working in fields that demand exceptional detail and surface quality, such as:

- Microtechnology Engineers: PμSL printers can produce microfluidic chips, micro gears, and other intricate components with unparalleled precision.

- Jewelry designers: The ability to create objects with smooth, polished surfaces makes PμSL ideal for crafting delicate and high-end jewelry pieces.

- Dental Professionals: Biocompatible resins used in PμSL printing can be utilized for creating highly detailed dental models and even custom prosthetics.

Adhesive Jet Metal 3D Printer

While traditional metal 3D printing often involves melting metal powder with lasers, a new contender has entered the ring: adhesive jet metal printing. This method uses a specialized inkjet printer head to deposit a binding agent onto a bed of metal powder. The printed object is then infiltrated with a liquid metal, creating a solid and functional metal part.

Advantages:

- Wider Material Compatibility: Compared to laser-based metal printing, adhesive jet technology offers a broader compatibility with various metal powders, including those with high melting points. This opens doors for applications requiring specific material properties.

- Reduced Thermal Stress: The lower heat involved in adhesive jet printing minimizes thermal distortion in the printed object, leading to improved dimensional accuracy and reduced post-processing needs.

- Multi-Material Printing: Certain adhesive jet printers offer the ability to print different binding agents within the same build. This allows for the creation of objects with varying properties within a single print, such as regions with different levels of porosity or conductivity.

Disadvantages:

- Lower Strength: Metal parts produced through adhesive jet printing might not achieve the same level of strength and durability compared to laser-sintered metal objects.

- Post-Processing Requirements: While thermal stress is reduced, adhesive jet-printed parts still require infiltration and potentially additional post-processing steps for complete functionality.

- Material Cost: Metal powders, especially those for exotic or high-performance applications, can be expensive, impacting the overall cost of printing.

A Multi-Material 3D Printing Equipment

Imagine a 3D printer that can weave together a symphony of materials within a single build. This is the reality of multi-material 3D printing. These versatile machines break free from the limitations of single-material printing, allowing you to create objects with a combination of properties and functionalities.

How Multi-Material Printing Works:

There are several approaches to multi-material printing, each with its own advantages and limitations. Some printers employ multiple extruders, each loaded with a different filament. As the print head moves, it selects the appropriate extruder based on the desired material for a specific section of the object. Other multi-material printers utilize a jetting system that deposits droplets of various materials onto the build platform.

Advantages:

- Enhanced Functionality: Multi-material printing allows you to integrate different functionalities within a single object. For instance, you could print a gripper with a rigid body and a flexible grasping surface.

- Reduced Assembly Needs: By combining multiple materials in one print, multi-material printers can eliminate the need for complex assembly processes, saving time and resources.

- Material Customization: The ability to combine materials opens doors for creating objects with tailored properties, such as varying levels of stiffness, color, and conductivity.

Disadvantages:

- Complexity of Use: Operating a multi-material printer requires a deeper understanding of different materials, their interactions, and printer settings compared to single-material printing.

- Support Material Removal: Certain multi-material printing techniques utilize support materials that need to be meticulously removed after printing, adding an extra step to the workflow.

- Limited Material Combinations: Not all materials are compatible with each other in a multi-material print. There might be limitations on which materials can be effectively combined within a single build.

Who Should Consider Multi-Material Printing?

This technology is ideal for applications where combining functionalities and material properties is crucial, such as:

- Product Prototyping: Multi-material printing allows for the creation of prototypes that closely mimic the final product’s intended functionality and aesthetics.

- Robotics: By integrating rigid and flexible materials, multi-material printing can be used to create custom grippers, robotic arms, and other robotic components.

- Consumer Electronics: Multi-material printing shows promise in producing electronic devices with integrated circuits, sensors, and housings within a single print.

A Large-Sized 3D Printer

While the ability to print intricate details is impressive, there’s also a growing demand for 3D printers capable of handling large-scale projects. Enter the world of large-sized 3D printers, also known as big-area additive manufacturing (BAAM) machines. These behemoths push the boundaries of size limitations, enabling the creation of objects previously unimaginable with traditional 3D printing.

Large-Sized 3D Printing Technologies:

There are various approaches to large-scale 3D printing, each catering to different needs. Some utilize fused deposition modeling (FDM) with specialized extrusion systems that can handle high-volume filament deposition. Others employ pellet extrusion, where plastic pellets are melted and extruded to create larger structures.

Advantages:

- Unprecedented Scale: Large-sized 3D printers allow you to print objects that would be impossible with conventional machines, opening doors for applications in construction, automotive prototyping, and even creating large-scale art installations.

- Reduced Material Costs: Certain large-sized printers can utilize more cost-effective materials like pellets or recycled plastics compared to filaments used in smaller printers.

- Faster Printing: For large objects, large-sized printers can offer faster printing speeds compared to scaling up prints on smaller machines.

Disadvantages:

- Significant Investment: The cost of large-sized 3D printers is considerably higher compared to desktop or even industrial-grade printers. This technology is primarily suited for professional applications with a high return on investment.

- Limited Material Selection: The focus on high-throughput printing in large-sized machines often comes with a trade-off in material diversity. The selection of compatible materials might be narrower compared to smaller printers.

- Space Requirements: These machines are not for the cramped hobbyist workshop. Large-sized 3D printers often require dedicated spaces with appropriate ventilation and power infrastructure.

Who Should Consider Large-Sized 3D Printing?

This technology is best suited for industries that can leverage the benefits of large-scale printing, such as:

- Construction: Large-sized 3D printers show promise in creating building components, architectural mockups, and even furniture directly on-site.

- Automotive: Large-sized 3D printing can be used to prototype car parts, create custom molds and jigs, and potentially even fabricate entire car bodies in the future.

- Marine Industry: The ability to print large and robust parts makes this technology well-suited for applications in shipbuilding, creating boat components, and even printing custom molds for large marine parts.

FAQ

Here are some of the most frequently asked questions regarding new 3D printing equipment:

| Question | Answer |

|---|---|

| What is the most affordable new 3D printing technology? | While affordability is relative, PμSL printers tend to be on the higher end due to their sophisticated technology. Multi-material printers can also be more expensive compared to single-material machines. Adhesive jet metal printing might offer a more cost-effective option for metal printing compared to laser-based techniques, but material costs can still be a factor. Large-sized 3D printers come with a significant initial investment. |

| What new 3D printing technology is easiest to use? | FDM-based multi-material printers with user-friendly interfaces might offer a more approachable entry point compared to PμSL or large-sized printers that require a deeper understanding of material properties and machine operation. |

| What new 3D printing technology is best for home use? | Due to size constraints, complex operation requirements, and potentially higher costs, most of these new technologies are better suited for professional or industrial environments. However, as 3D printing technology continues to evolve, more user-friendly and affordable versions of these innovative machines might become available for home hobbyists in the future. |

| Where can I find more information about new 3D printing equipment? | Many 3D printer manufacturers have detailed information on their websites showcasing their latest machines and technologies. Industry publications, online communities, and 3D printing events are also great resources to stay updated on the latest advancements. |

The world of 3D printing is constantly evolving, and these new technologies represent just a glimpse of the exciting possibilities that lie ahead. As these machines become more refined, accessible, and affordable, we can expect to see a surge in their adoption across various industries. From creating intricate medical devices to building entire houses, the future of 3D printing is brimming with potential, and these innovative machines are poised to be the architects of a new era of creation.

Share On

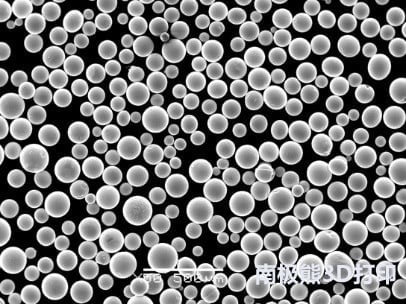

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731