3D printing Metal Powder:Precautions of Water Atomization

Table of Contents

Imagine sculpting intricate objects not from clay or wood, but from atomized metal dust. This futuristic vision is becoming a reality thanks to 3D Printing Metal Powder technology, and a crucial step in this process is the creation of fine, high-quality metal powders. Among the various methods available, water atomization stands out for its cost-effectiveness and efficiency. However, this seemingly straightforward process harbors potential hazards that demand meticulous precautions to ensure a safe and successful operation.

Delving into the Depths of Water Atomization 3D Printing Metal Powder

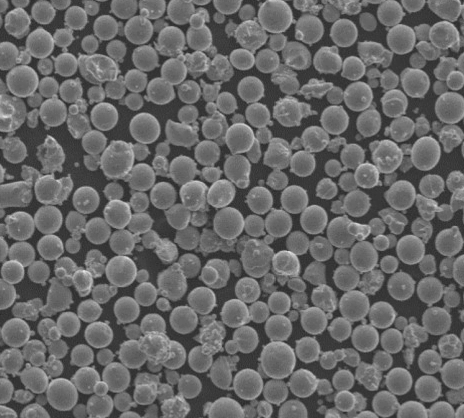

Before we delve into the safety measures, let’s understand the essence of water atomization. Picture molten metal, heated to a scorching temperature, being forced through a small nozzle. High-pressure water jets then collide with this molten stream, shattering it into tiny droplets that solidify mid-air, forming the coveted metal powder. This seemingly simple process, however, involves a delicate interplay of molten metal properties, water pressure, and atomization parameters, all of which can significantly impact the final powder characteristics and safety risks.

Environmental Protection: Mitigating the Impact on Our Surroundings

1. Water Treatment and Recycling:

Water atomization, as the name suggests, utilizes copious amounts of water. This water comes into close contact with the molten metal, potentially becoming contaminated with metal oxides, dust particles, and other pollutants. Releasing this untreated water back into the environment can have detrimental consequences for aquatic life and overall ecosystem health.

Solution: Implementing robust water treatment systems is paramount. These systems employ filtration, chemical precipitation, and other techniques to remove contaminants, rendering the water safe for either re-use in the atomization process or for responsible disposal in accordance with environmental regulations.

2. Air Quality Control:

The atomization process also generates airborne metal dust. This fine dust, if not adequately controlled, can pose respiratory health risks to workers and potentially contribute to air pollution.

Solution: Installing efficient air filtration systems is crucial. These systems, like baghouses or electrostatic precipitators, capture the metal dust before it escapes into the atmosphere, ensuring a safe working environment and minimizing environmental impact.

Production Safety: Prioritizing the Well-being of Personnel

1. Personal Protective Equipment (PPE):

Working with molten metal and high-pressure water inherently carries safety risks. Workers engaged in the water atomization process must be equipped with appropriate personal protective equipment (PPE). This includes heat-resistant clothing, gloves, and face shields to protect against burns and splashes.

2. Pressure Vessel Safety:

The heart of the water atomization process lies in the pressure vessel that houses the molten metal. This vessel operates under immense pressure, and any failure could result in catastrophic consequences.

Solution: Regular inspection and maintenance of the pressure vessel are essential. This includes adhering to strict safety protocols, conducting non-destructive testing to identify potential flaws, and replacing any worn-out components. Additionally, training personnel in emergency procedures and pressure vessel safety best practices is crucial.

3. Noise Control:

The high-pressure water jets and the shattering of molten metal generate significant noise during the atomization process. Prolonged exposure to such noise levels can lead to hearing damage for workers.

Solution: Implementing noise control measures like acoustic enclosures around the atomization equipment and providing hearing protection to workers can significantly reduce these risks.

Choosing the Right Partners: A Crucial Step for Success

Selecting the right equipment manufacturers and service providers is critical for ensuring the safety and efficiency of your water atomization setup. Look for companies with a proven track record in safety compliance, equipment quality, and reliable after-sales support. Collaborating with experienced professionals can provide valuable guidance in setting up and maintaining a safe and productive water atomization operation.

Unveiling the Advantages and Considerations of Water Atomization

While water atomization offers numerous advantages, such as cost-effectiveness and high production rates, it’s crucial to weigh these benefits against the inherent complexities and safety considerations involved. Compared to other methods like gas atomization, water atomization generally produces less spherical and more irregular powder particles. These characteristics might not be suitable for all 3D printing Metal Powder applications. Additionally, water contamination and corrosion risks need careful management to ensure consistent powder quality and equipment longevity.

FAQ

Q: What are the key environmental concerns associated with water atomization?

A: The primary environmental concerns include:

- Water pollution: Untreated water containing metal contaminants can harm aquatic life and disrupt ecosystems.

- Air pollution: Uncontrolled metal dust emissions can pose respiratory health risks and contribute to air quality issues.

Q: How can I ensure proper water treatment and recycling in my water atomization setup?

A: Implementing a multi-stage treatment system is recommended. This may involve:

- Coagulation and flocculation: To remove suspended solids and metal oxides.

- Filtration: To remove remaining particles and impurities.

- Chemical precipitation: To remove specific metal ions.

- pH adjustment: To optimize treatment efficiency and ensure safe disposal.

Consulting with water treatment specialists is crucial to design a system that effectively addresses the specific contaminants present in your process water.

Q: What are some additional safety considerations for workers involved in water atomization?

A: In addition to the mentioned PPE and pressure vessel safety measures, the following precautions are important:

- Proper training: All personnel involved in the operation should receive comprehensive training on safety protocols, emergency procedures, and proper handling of equipment.

- Signage and hazard communication: Clearly visible signage and labels should be placed around the facility to warn of potential hazards and safety instructions.

- Regular safety audits: Conducting regular audits helps identify potential safety risks and ensure adherence to safety regulations.

Q: How can I choose the right equipment and service providers for my water atomization needs?

A: Consider the following factors when selecting equipment and service providers:

- Experience and reputation: Look for companies with a proven track record in water atomization technology and safety compliance.

- Equipment quality: Choose reliable and durable equipment that meets industry standards and your specific production requirements.

- After-sales support: Ensure the provider offers comprehensive after-sales support, including maintenance services, troubleshooting assistance, and spare parts availability.

- Regulatory compliance: Verify that the equipment and services comply with all relevant safety and environmental regulations in your region.

By carefully evaluating these factors, you can select partners who can support you in establishing a safe, efficient, and sustainable water atomization operation.

Conclusion: A Balancing Act – Safety, Efficiency, and Sustainability

Water atomization offers a compelling solution for producing metal powders for various applications, including 3D printing. However, navigating the intricacies of this process requires a multifaceted approach that prioritizes safety, environmental protection, and production efficiency. Implementing the precautions outlined above, coupled with responsible water management and collaboration with qualified partners, can help you achieve successful and sustainable water atomization operations, paving the way for innovative advancements in the world of 3D metal printing.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731