Aluminum copper 3D metal powders

Table of Contents

Imagine building complex shapes with the strength of aluminum and the electrical conductivity of copper. That’s the magic of Aluminum copper 3D metal powders, a revolutionary material transforming the landscape of additive manufacturing. This isn’t science fiction; it’s the cutting edge, allowing engineers and designers to create intricate parts with exceptional properties.

But before we delve deeper, let’s rewind a bit. 3D printing, also known as additive manufacturing, has become a game-changer for creating objects layer by layer from digital models. This technology offers unparalleled design freedom and customization, pushing the boundaries of traditional manufacturing. However, for many applications, the material selection has been limited. That’s where Aluminum copper 3D metal powderssteps in, offering a unique blend of desirable characteristics.

Understanding Aluminum copper 3D metal powders

Aluminum copper powder, as the name suggests, is a composite material where aluminum particles are meticulously combined with copper particles. The specific ratio of these elements can be adjusted to achieve desired properties in the final printed part. This allows for a spectrum of possibilities, from prioritizing lightweight aluminum to emphasizing the superior conductivity of copper.

Here’s a table summarizing the key details of aluminum copper 3D metal powder:

| Key Details | Description |

|---|---|

| Material Type | Composite Metal Powder |

| Base Materials | Aluminum and Copper |

| Production Method | Atomization or Gas Atomization |

| Application | Additive Manufacturing (3D Printing) |

| Benefits | Lightweight, Conductive, Customizable |

the Composition and Properties of Aluminum Copper Powders

The magic of aluminum copper 3D metal powder lies in its composition and the resulting properties. Let’s break it down further:

| Compositional Variations | Properties |

|---|---|

| High Aluminum (Al > Cu) | Lightweight, good mechanical strength, moderate conductivity |

| Balanced Aluminum-Copper (Al ≈ Cu) | Balanced combination of weight, strength, and conductivity |

| High Copper (Cu > Al) | Excellent electrical conductivity, good heat dissipation, lower strength compared to high aluminum variants |

Applications of Aluminum Copper 3D Metal Powder

The unique properties of aluminum copper 3D metal powder open doors to a vast array of applications. Here are some exciting possibilities:

| Application | Reason for Use |

|---|---|

| Aerospace Components | Lightweight and conductive for heat sinks, electrical components, and structural parts |

| Automotive Parts | Lightweight for improved fuel efficiency, conductive for wiring harnesses and heat exchangers |

| Electronics | Excellent conductivity for heat sinks, waveguides, and electrical enclosures |

| Medical Devices | Biocompatible options for implants and prosthetics that combine strength and weight savings |

| Consumer Electronics | Lightweight and conductive for mobile phone components, heat sinks in laptops, and customized enclosures |

Examples of Aluminum Copper 3D Metal Powder Models

With the growing demand for this innovative material, several manufacturers offer aluminum copper 3D metal powders with varying compositions and specifications. Here are ten specific models to consider:

| Model Name | Manufacturer | Composition | Key Features |

|---|---|---|---|

| ALSi10MgCu | Höganäs AB | AlSi10Mg + Cu | Good balance of strength, weight, and conductivity |

| EOS AluminiumCu | EOS GmbH | Customizable Al-Cu ratio | Tailored properties for specific applications |

| SLM Solutions AlCu40 | SLM Solutions GmbH | Al + 40% Cu | High electrical conductivity, ideal for heat sinks |

| Renishaw AM260 | Renishaw plc | AlSi7MgCu0.5 | Lightweight with improved conductivity compared to pure aluminum |

| Carpenter Incus | Carpenter Additive Manufacturing | Customizable Al-Cu ratio with optional additives | High-performance option for demanding applications |

| LPW AlSi10MgCu | LPW Technology Ltd | AlSi10Mg + Cu | Combines printability with good mechanical properties and conductivity |

| ExOne AlSi9Cu3 | ExOne | AlSi9Cu3 | Optimized for binder jet 3D printing, offering good conductivity |

| Elementum 3D AMCopper-100 | Elementum 3D | Commercially pure copper | Excellent conductivity for electrical applications |

| Poliflor Metal Additive Manufacturing پودر آلومینیوم مس (Aluminum Copper Powder)** | Poliflor Metal Additive Manufacturing | Customizable Al-Cu ratio | Offers options for the Iranian market |

| Additive Industries Alumina Copper | Additive Industries | Customizable Al-Cu ratio | Suitable for Metal Injection Molding (MIM) alongside 3D printing |

Specifications, Sizes, Grades, and Standards

Choosing the right aluminum copper 3D metal powder requires considering various specifications, sizes, grades, and standards. Here’s a breakdown to guide your selection:

- Particle Size Distribution: This refers to the range of particle sizes within the powder. A finer powder generally produces smoother surface finishes on printed parts but may require adjustments in printing parameters. Conversely, a coarser powder can offer faster printing speeds but might result in a rougher surface texture.

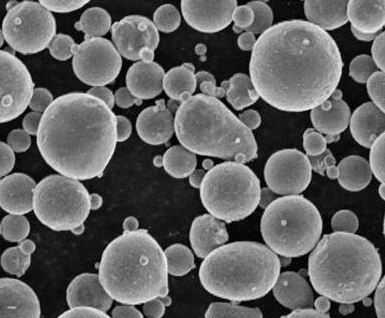

- Sphericity: Ideally, the powder particles should be as spherical as possible. This ensures optimal flow during printing and minimizes voids within the finished part. Highly spherical powders often command a premium price.

- Flowability: Good flowability is essential for consistent material feeding during the 3D printing process. Powder with poor flowability can lead to feeding issues and inconsistencies in the printed part.

- Apparent Density: This refers to the weight of the powder per unit volume. A higher apparent density can translate to faster printing speeds and potentially lower material costs.

- Chemical Composition: The specific ratio of aluminum and copper, along with any additional elements, will significantly impact the final properties of the printed part. Look for manufacturers who provide detailed chemical composition information for their powders.

- Standards: Several industry standards govern the specifications of metal powders for additive manufacturing. Common standards include ASTM International (ASTM) and the International Organization for Standardization (ISO). Following these standards ensures consistent quality and performance of the powder.

Suppliers and Pricing

Several reputable suppliers offer aluminum copper 3D metal powder. Here are some factors to consider when choosing a supplier:

- Product Portfolio: Look for a supplier with a diverse selection of aluminum copper powders with varying compositions and specifications to match your specific project requirements.

- Quality Control: Ensure the supplier adheres to strict quality control procedures to guarantee consistent powder characteristics.

- Technical Support: Reliable technical support from the supplier can be invaluable for troubleshooting printing issues and optimizing your process.

- Pricing: The cost of aluminum copper 3D metal powder can vary depending on the composition, particle size, and supplier. Request quotes from several suppliers to compare pricing and find the best value for your needs.

Advantages and Limitations of Aluminum Copper 3D Metal Powder

While aluminum copper 3D metal powder offers exciting possibilities, it’s essential to understand its advantages and limitations:

Advantages:

- Lightweight: Aluminum copper parts can be significantly lighter than pure aluminum parts, offering weight savings in applications like aerospace and automotive.

- Conductive: The presence of copper enhances the electrical conductivity compared to pure aluminum, making it suitable for heat sinks, electrical components, and waveguides.

- Customizable Properties: By adjusting the ratio of aluminum and copper, manufacturers can tailor the properties of the powder to meet specific application needs.

- Design Freedom: 3D printing allows for complex geometries that might be challenging or impossible with traditional manufacturing techniques.

- Reduced Waste: 3D printing minimizes material waste compared to subtractive manufacturing techniques.

Limitations:

- Cost: Aluminum copper 3D metal powder can be more expensive than pure aluminum powder.

- Mechanical Strength: While some aluminum copper alloys offer good mechanical strength, they might not be suitable for applications requiring the highest strength.

- Limited Availability: Compared to widely available aluminum powders, aluminum copper options might have a smaller selection from some suppliers.

- Aerospace Heat Sinks: Traditional heat sinks in aircraft are often made from aluminum. However, by incorporating copper into the 3D printed heat sink using aluminum copper powder, engineers can achieve lighter weight while maintaining excellent heat dissipation capabilities. This translates to improved fuel efficiency for airplanes and spacecraft.

- Electric Vehicle (EV) Battery Trays: The ever-growing EV industry demands lightweight and conductive materials for battery enclosures. Aluminum copper 3D metal powder offers the perfect blend – reducing overall vehicle weight while ensuring efficient heat management for the battery pack, optimizing performance and range.

- Medical Implants: Biocompatible aluminum copper alloys can be 3D printed for customized implants and prosthetics. The combination of lightweight properties and improved bone ingrowth potential compared to pure titanium implants makes this a promising development in the medical field.

- Customizable Electronics Housings: The ability to 3D print with aluminum copper powder allows for the creation of intricate and lightweight housings for electronic devices. This can be particularly beneficial for applications where both weight reduction and heat management are crucial, such as laptops and mobile phones.

- High-Performance Waveguides: In radar systems and communication technologies, waveguides play a vital role in transmitting electromagnetic waves. Aluminum copper 3D printed waveguides offer exceptional signal conductivity while maintaining a lightweight advantage over traditional brass waveguides.

These are just a few examples, and as the technology matures, we can expect even more innovative applications for aluminum copper 3D metal powder.

FAQ

Here are some frequently asked questions regarding aluminum copper 3D metal powder, answered in a table format:

| Question | Answer |

|---|---|

| What are the benefits of using aluminum copper 3D metal powder? | Lighter weight, improved conductivity, customizable properties, design freedom, and reduced waste. |

| What are the limitations of aluminum copper 3D metal powder? | Higher cost compared to pure aluminum powder, potentially lower mechanical strength depending on the composition, limited availability from some suppliers, and the need for optimized printing parameters. |

| What are some typical applications of aluminum copper 3D metal powder? | Aerospace heat sinks, electric vehicle battery trays, medical implants, customizable electronics housings, and high-performance waveguides. |

| How does aluminum copper 3D metal powder compare to other metal powders for 3D printing? | Aluminum copper offers a unique combination of lightweight properties and improved conductivity compared to pure aluminum, while potentially offering better strength-to-weight ratio than pure copper for some applications. |

| What are some factors to consider when choosing an aluminum copper 3D metal powder supplier? | Look for a supplier with a diverse product portfolio, rigorous quality control procedures, reliable technical support, and competitive pricing. |

The Future of Aluminum Copper 3D Metal Powder

The future of aluminum copper 3D metal powder is bright. As research and development efforts continue, we can expect advancements in:

- Powder development: New alloys and compositions might be formulated to offer even better combinations of strength, weight, and conductivity.

- Printing technology: Advancements in 3D printing techniques might allow for faster and more efficient printing of aluminum copper parts.

- Standardization: The development of more robust industry standards for aluminum copper 3D metal powder will ensure consistent quality and performance across different suppliers.

With these advancements, aluminum copper 3D metal powder has the potential to revolutionize various industries by enabling the creation of lightweight, conductive, and complex parts with exceptional properties. This innovative material is poised to play a significant role in shaping the future of additive manufacturing.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731