aluminum magnesium 3D metal powder

Table of Contents

Imagine building complex, high-strength objects layer by layer, with the freedom of design only limited by your imagination. This is the power of 3D printing, also known as additive manufacturing. But what if you could 3D print metal objects that are not only intricate but also lightweight and durable? Enter aluminum magnesium 3D metal powder, a revolutionary material taking the additive manufacturing industry by storm.

Detailed Introduction of Aluminum Magnesium 3D Metal Powder

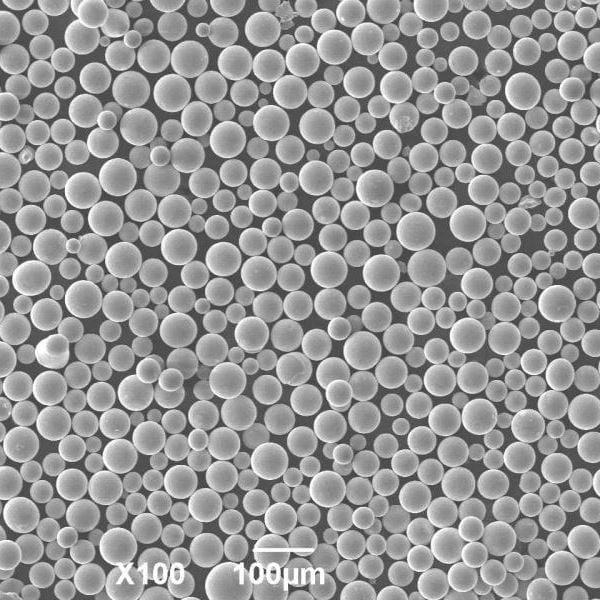

Aluminum magnesium 3D metal powder is a composite material specifically designed for use in additive manufacturing processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM). It consists of tiny, spherical particles of aluminum alloyed with magnesium and other elements. This combination offers a unique blend of properties that make it ideal for creating high-performance metal parts.

Here’s a breakdown of the key components:

- Aluminum: The primary element, known for its lightness, excellent corrosion resistance, and good formability.

- Magnesium: Added in small percentages to enhance strength-to-weight ratio and improve weldability.

- Other Elements (Optional): Depending on the specific alloy, additional elements like silicon, copper, or manganese might be included to further fine-tune properties for desired applications.

The size and distribution of these metal powder particles are crucial for successful 3D printing. Generally, the particles range from 15 to 100 microns in diameter, ensuring smooth flow during the printing process while maintaining enough detail for precise object creation.

Properties and Characteristics of Aluminum Magnesium 3D Metal Powder

| Property | Description |

|---|---|

| Density | Lower than pure aluminum, making it ideal for lightweight applications. |

| Strength | Varies depending on the specific alloy. Generally, offers good strength-to-weight ratio. |

| Corrosion Resistance | Excellent corrosion resistance, similar to pure aluminum. |

| Weldability | Improved weldability compared to pure aluminum due to the presence of magnesium. |

| Thermal Conductivity | Good thermal conductivity, making it suitable for applications requiring heat dissipation. |

| Electrical Conductivity | Lower electrical conductivity compared to pure aluminum. |

| Biocompatibility | Some aluminum-magnesium alloys exhibit good biocompatibility, making them suitable for medical applications. |

These properties make aluminum magnesium 3D metal powder a versatile material with a wide range of potential applications.

The Application Areas of Aluminum Magnesium 3D Metal Powder

| Application Area | Advantages | Examples |

|---|---|---|

| Aerospace: | Lightweight, high strength-to-weight ratio, good corrosion resistance | Aircraft components, rocket parts, satellite structures |

| Automotive: | Lightweighting vehicle components for improved fuel efficiency | Engine parts, suspension components, body panels |

| Consumer Electronics: | Lightweight, intricate designs for functional and aesthetic purposes | Heat sinks, camera housings, structural components in laptops |

| Medical & Dental: | Biocompatible options for implants and prosthetics | Bone implants, dental bridges, surgical instruments |

| Sporting Goods: | Lightweight, high-performance components for enhanced athletic performance | Bicycle frames, golf clubs, running shoe components |

The ability to create complex geometries with aluminum magnesium 3D metal powder opens doors for innovation in various fields. Imagine creating custom-designed, lightweight prosthetics that perfectly fit an individual’s needs. Or, think of 3D-printed aircraft parts that are both strong and lightweight, improving fuel efficiency and flight range. The possibilities are truly endless.

Specific Metal Powder Models and Their Descriptions

Now, let’s delve deeper into some specific aluminum magnesium 3D metal powder models available in the market:

- AlSi10Mg: This is a widely used alloy containing around 9-11% silicon and a small amount of magnesium. It offers a good balance of strength, ductility, and castability, making it ideal for a variety of applications, including automotive parts, structural components, and heat sinks.

- AA2024: A high-strength aluminum alloy containing copper and magnesium. It boasts superior strength-to-weight ratio but can be slightly more susceptible to corrosion compared to AlSi10Mg. AA2024 is a popular choice for aerospace applications like aircraft parts and spacecraft components.

- Scalmalloy: This is a commercially available aluminum-magnesium scandium alloy known for its exceptional strength and high-temperature performance. The addition of scandium significantly enhances strength and allows for operation at elevated temperatures. Scalmalloy is particularly attractive for demanding applications in the aerospace and motorsport industries.

- AMSU 100: This aluminum-silicon-magnesium alloy is specifically designed for additive manufacturing processes like SLM. It offers excellent flowability for smooth printing and good mechanical properties, making it suitable for various applications across industries such as automotive and consumer electronics.

- Gasar A4: This aluminum-magnesium alloy boasts superior fatigue strength and good corrosion resistance. It’s particularly well-suited for applications requiring high cyclic loading, such as components in engines and transmissions.

- Custom Alloys: The beauty of additive manufacturing lies in its customization potential. Several manufacturers offer the ability to develop aluminum-magnesium alloys with specific properties tailored to unique application needs. This opens doors for even more innovative creations in the future.

Here’s a table summarizing the key characteristics of some popular aluminum magnesium 3D metal powder models:

| Alloy | Description | Key Properties | Applications |

|---|---|---|---|

| AlSi10Mg | Widely used alloy with Si and Mg | Good balance of strength, ductility, castability | Automotive parts, structural components, heat sinks |

| AA2024 | High-strength alloy with Cu and Mg | Superior strength-to-weight ratio, good machinability | Aerospace parts, spacecraft components |

| Scalmalloy | Al-Mg-Sc alloy | Exceptional strength, high-temperature performance | Aerospace applications, motorsport components |

| AM3004 | Al-Mg alloy | Good balance of strength, corrosion resistance, weldability | General applications across industries |

| AMSU 100 | Al-Si-Mg alloy for SLM | Excellent flowability, good mechanical properties | Automotive, consumer electronics |

| Gasar A4 | Al-Mg alloy | Superior fatigue strength, good corrosion resistance | Engine and transmission components |

Choosing the Right Aluminum Magnesium 3D Metal Powder:

Selecting the most suitable aluminum magnesium 3D metal powder depends on the specific application requirements. Here are some key factors to consider:

- Strength: The required strength of the final printed part. Consider factors like static load, fatigue loading, and impact resistance.

- Weight: The importance of lightweighting the component. Aluminum magnesium alloys excel in this area.

- Corrosion Resistance: The environment in which the part will operate. Some alloys offer superior corrosion resistance compared to others.

- Thermal Conductivity: The need for heat dissipation in the application.

- Biocompatibility: For medical applications, biocompatible options are crucial.

- Printability: The powder’s flowability and suitability for the chosen 3D printing process.

Consulting with a material specialist or the metal powder supplier can be highly beneficial in selecting the optimal aluminum magnesium alloy for your specific needs.

Advantages and Limitations of Aluminum Magnesium 3D Metal Powder

Advantages:

- Lightweight: Significantly reduces weight compared to traditional metal components, leading to improved fuel efficiency in applications like aerospace and automotive.

- High Strength-to-Weight Ratio: Offers excellent strength while maintaining a lightweight profile.

- Good Corrosion Resistance: Many aluminum magnesium alloys exhibit excellent corrosion resistance, similar to pure aluminum.

- Design Freedom: Additive manufacturing allows for complex geometries and intricate designs, unlocking new possibilities for product development.

- Improved Weldability: The presence of magnesium in some alloys enhances weldability compared to pure aluminum.

- Biocompatible Options: Certain aluminum-magnesium alloys demonstrate good biocompatibility, making them suitable for medical applications like implants and prosthetics.

Limitations:

- Limited Material Selection: Compared to traditional metal fabrication techniques, the selection of aluminum magnesium alloys specifically designed for 3D printing is still evolving.

- Cost: 3D printing metal powder can be more expensive than traditional manufacturing methods, especially for high-volume production.

- Surface Finish: 3D printed metal parts may require additional post-processing for a smoother surface finish.

- Material Properties: The mechanical properties of 3D printed metal parts can vary slightly compared to traditionally manufactured parts due to the layer-by-layer printing process.

Despite these limitations, the advantages of aluminum magnesium 3D metal powder are undeniable. As technology advances and production costs decrease, we can expect this revolutionary material to play an increasingly significant role in various industries.

Suppliers and Pricing

The availability and pricing of aluminum magnesium 3D metal powder can vary depending on the specific alloy, particle size, and supplier. Here’s a general overview:

- Suppliers: Several reputable companies supply aluminum magnesium 3D metal powder, including:

- APWorks

- Höganäs

- SLM Solutions

- ExOne

- Norsk Hydro

- Pricing: Pricing for aluminum magnesium 3D metal powder is typically higher than conventional metal fabrication materials but varies based on factors like:

- Alloy: More complex alloys with additional elements might be more expensive.

- Particle Size: Finer particle sizes generally command a higher price.

- Quantity: Bulk purchases often come with discounted pricing.

It’s recommended to contact potential suppliers directly for specific quotes and to discuss your application requirements. Many suppliers offer material datasheets that detail the properties, specifications, and pricing of their aluminum magnesium 3D metal powder offerings.

FAQ

Q: What are the benefits of using aluminum magnesium 3D metal powder over traditional metal manufacturing methods?

A: Aluminum magnesium 3D metal powder offers several advantages, including:

- Lightweighting: Significantly reduces weight for improved efficiency in applications like aerospace and automotive.

- Design Freedom: Enables creation of complex geometries and intricate designs for innovative products.

- Faster Time-to-Market: Prototyping and small-scale production can be achieved quickly with 3D printing.

- Reduced Material Waste: Minimizes material waste compared to subtractive manufacturing techniques.

Q: Are there any health concerns associated with aluminum magnesium 3D metal powder?

A: Aluminum and magnesium themselves are generally considered safe materials. However, the handling of metal powder can pose inhalation risks. It’s crucial to follow proper safety protocols when working with 3D metal powders, including using appropriate personal protective equipment (PPE) like respirators and gloves.

Q: What are the future prospects for aluminum magnesium 3D metal powder?

A: The future of aluminum magnesium 3D metal powder appears bright. As technology advances, we can expect:

- Development of new alloys: With more options offering a wider range of properties for diverse applications.

- Reduced production costs: Making 3D printing metal parts more cost-competitive with traditional methods.

- Improved printability: Leading to smoother surface finishes and potentially faster printing speeds.

- Wider adoption across industries: Unlocking new possibilities for innovation in various sectors.

Aluminum magnesium 3D metal powder is a revolutionary material with the potential to transform various industries. Its unique blend of lightweight properties, good strength, and design freedom makes it a valuable tool for engineers and designers. As technology continues to evolve, we can expect even more exciting developments in the world of aluminum magnesium 3D metal powder printing.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731