Blog

all colletions

Precision Robotic Linkages 3D Printed in Aluminum

Introduction – The Critical Role of Precision Linkages in Robotics In the dynamic and rapidly evolving field of robotics, precision is paramount. Every component within a robotic system plays a crucial role in its overall performance, accuracy, and reliability. Among these components, linkages stand out as essential elements that directly

Patient-Specific Knee Implants via Metal 3D Printing: Revolutionizing Orthopedic Care

Introduction – The Paradigm Shift in Knee Replacement with Metal 3D Printing The landscape of orthopedic surgery is undergoing a significant transformation, driven by advancements in additive manufacturing, commonly known as metal 3D printing. Among the most impactful applications is the production of patient-specific knee implants. Traditional, off-the-shelf knee replacements

3D Printing Dental Implant Abutments

Introduction: The Growing Role of 3D Printing in Dental Implantology The landscape of dental implantology is undergoing a significant transformation, driven by advancements in digital technologies and innovative manufacturing processes. Among these, metal 3D printing, also known as metal additive manufacturing, is emerging as a powerful tool for the fabrication

3D Printed Surgical Clamps with Stainless Steel

Introduction In the demanding world of surgical instruments, precision, reliability, and biocompatibility are paramount. Traditional manufacturing methods for surgical clamps often involve complex machining processes, leading to longer lead times and potential limitations in design complexity. Enter metal 3D printing, a transformative technology that is revolutionizing the way these critical

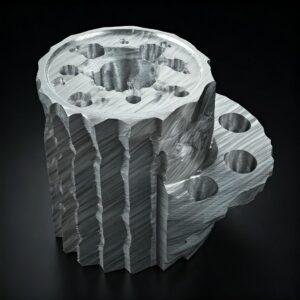

3D Printing Injection Mold Cores with Maraging Steel

Introduction – The Power of Metal 3D Printing for Advanced Injection Mold Cores In today’s rapidly evolving manufacturing landscape, the demand for complex geometries, reduced lead times, and enhanced performance is constantly increasing. Traditional manufacturing methods for injection mold cores often face limitations in terms of design freedom, production speed,

Custom Cutting Tools with Metal 3D Printing

In the relentless pursuit of efficiency and precision, manufacturing industries worldwide are constantly seeking innovative solutions to enhance their processes. At the forefront of this revolution lies metal additive manufacturing, more commonly known as metal 3D printing. This transformative technology is reshaping how complex components are designed and produced, and

Precision Robotic Linkages 3D Printed in Aluminum

Introduction – The Critical Role of Precision Linkages in Robotics In the dynamic and rapidly evolving field of robotics, precision is paramount. Every component within

Patient-Specific Knee Implants via Metal 3D Printing: Revolutionizing Orthopedic Care

Introduction – The Paradigm Shift in Knee Replacement with Metal 3D Printing The landscape of orthopedic surgery is undergoing a significant transformation, driven by advancements

3D Printing Dental Implant Abutments

Introduction: The Growing Role of 3D Printing in Dental Implantology The landscape of dental implantology is undergoing a significant transformation, driven by advancements in digital

3D Printed Surgical Clamps with Stainless Steel

Introduction In the demanding world of surgical instruments, precision, reliability, and biocompatibility are paramount. Traditional manufacturing methods for surgical clamps often involve complex machining processes,

3D Printing Injection Mold Cores with Maraging Steel

Introduction – The Power of Metal 3D Printing for Advanced Injection Mold Cores In today’s rapidly evolving manufacturing landscape, the demand for complex geometries, reduced

Custom Cutting Tools with Metal 3D Printing

In the relentless pursuit of efficiency and precision, manufacturing industries worldwide are constantly seeking innovative solutions to enhance their processes. At the forefront of this

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731