Blog

all colletions

Nickel-Based Superalloys

Overview Nickel-based superalloys are the backbone of modern high-performance engineering applications, especially in industries that demand extreme durability and resistance to high temperatures. These superalloys are a marvel of material science, exhibiting exceptional strength, oxidation resistance, and creep resistance. They are predominantly used in aerospace, power generation, and chemical processing

The Guide of Maraging Steel

When you think about high-strength materials used in aerospace, tooling, and other critical applications, maraging steel stands out. It’s the superhero of the steel world, boasting incredible strength and toughness while maintaining good malleability. But what exactly is maraging steel? How does it differ from other steels? And why should

Depowdering System

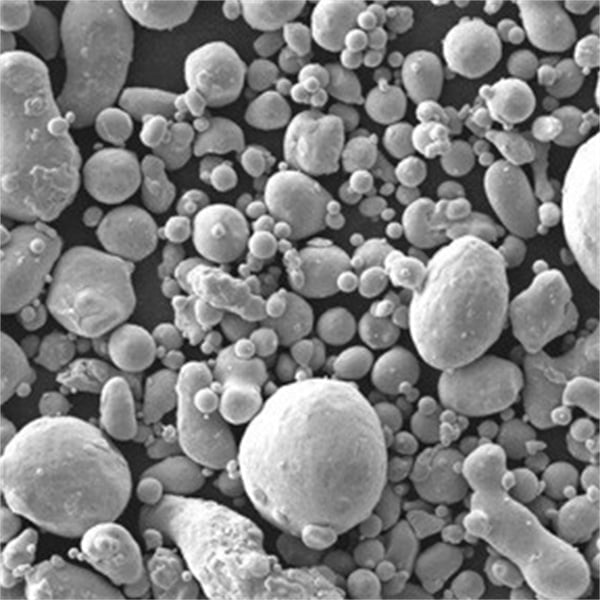

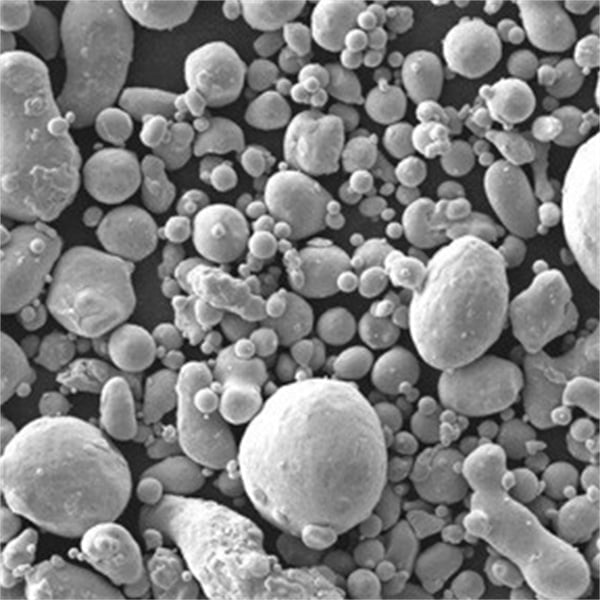

Additive manufacturing, more commonly known as 3D printing, has taken the world by storm. From prototyping to full-scale production, it offers unprecedented flexibility and efficiency. One crucial but often overlooked aspect of this process is depowdering. Let’s dive deep into the world of depowdering systems, explore various metal powders, their

High-Temperature Build Bed Assembly

High-temperature build bed assembly is a critical component in many industrial applications, particularly in 3D printing and additive manufacturing. This process involves using advanced materials capable of withstanding high temperatures to ensure precise, reliable, and efficient production. In this article, we’ll dive into the nuances of high-temperature build bed assembly,

Liquid Metal Jetting

Liquid Metal Jetting (LMJ) is revolutionizing the world of additive manufacturing. If you’re diving into this topic, you’re probably curious about how it works, what metals you can use, and its applications. Buckle up because we’re going on a comprehensive journey through the ins and outs of Liquid Metal Jetting.

Cold Spray Additive Manufacturing Technology

Cold Spray Additive Manufacturing technology is revolutionizing the world of manufacturing. This groundbreaking technique allows for the creation and repair of metal components with unprecedented precision and efficiency. In this article, we’ll dive deep into the world of CSAM, exploring its applications, advantages, limitations, and much more. Overview of Cold

Nickel-Based Superalloys

Overview Nickel-based superalloys are the backbone of modern high-performance engineering applications, especially in industries that demand extreme durability and resistance to high temperatures. These superalloys

The Guide of Maraging Steel

When you think about high-strength materials used in aerospace, tooling, and other critical applications, maraging steel stands out. It’s the superhero of the steel world,

Depowdering System

Additive manufacturing, more commonly known as 3D printing, has taken the world by storm. From prototyping to full-scale production, it offers unprecedented flexibility and efficiency.

High-Temperature Build Bed Assembly

High-temperature build bed assembly is a critical component in many industrial applications, particularly in 3D printing and additive manufacturing. This process involves using advanced materials

Liquid Metal Jetting

Liquid Metal Jetting (LMJ) is revolutionizing the world of additive manufacturing. If you’re diving into this topic, you’re probably curious about how it works, what

Cold Spray Additive Manufacturing Technology

Cold Spray Additive Manufacturing technology is revolutionizing the world of manufacturing. This groundbreaking technique allows for the creation and repair of metal components with unprecedented

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

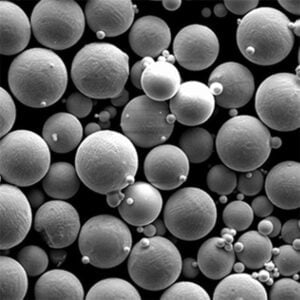

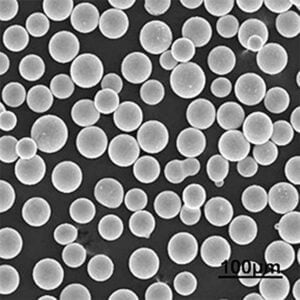

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731