Blog

all colletions

Metal Powders for High-Stress Engine Applications

In the fast-paced world of engineering, where performance and durability are non-negotiable, the materials we use can make or break the success of a project. High-stress engine applications, such as those found in aerospace, automotive, and industrial machinery, demand materials that can withstand extreme conditions without compromising on reliability. Enter

High-Temperature Rocket Engine

Rocket engines are marvels of engineering, driving humanity’s quest to explore the cosmos. Among them, high-temperature rocket engines stand out for their capability to operate under extreme thermal conditions. This article delves into the complexities of high-temperature rocket engines, exploring the specific metal powder models used, their composition, properties, applications,

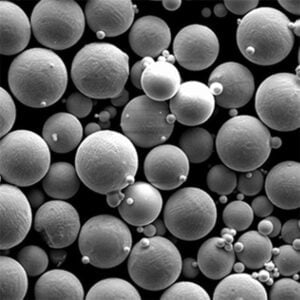

Plasma Atomisation

Plasma atomisation is a fascinating and highly technical process that transforms metal into fine powder using plasma torches. This article delves deep into the science and applications of plasma atomisation, providing a detailed and SEO-optimized overview of this advanced technology. From its benefits and drawbacks to specific metal powder models,

Electrode Induction Melting Inert Gas Atomisation

Overview Electrode Induction Melting Inert Gas Atomisation (EIGA) is a cutting-edge process used to produce high-quality metal powders. This technique, known for its precision and efficiency, involves melting metal electrodes through induction heating in an inert gas atmosphere, followed by atomisation to form fine metal powders. EIGA is widely employed

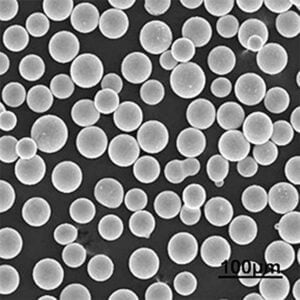

Inert Gas Atomisation

In the ever-evolving world of metallurgy and material science, the production of high-quality metal powders is crucial for various advanced manufacturing processes. One method that stands out for its precision and efficiency is Inert Gas Atomisation (IGA). This technique is widely used to produce fine, spherical metal powders with uniform

Vacuum Induction Melting

Overview of Vacuum Induction Melting Vacuum induction melting (VIM) is a sophisticated and essential process in the metallurgy industry, used primarily to produce high-quality metal alloys. By melting metals under a vacuum, this method minimizes the risk of contamination from gases and impurities, resulting in superior material properties. It’s widely

Metal Powders for High-Stress Engine Applications

In the fast-paced world of engineering, where performance and durability are non-negotiable, the materials we use can make or break the success of a project.

High-Temperature Rocket Engine

Rocket engines are marvels of engineering, driving humanity’s quest to explore the cosmos. Among them, high-temperature rocket engines stand out for their capability to operate

Plasma Atomisation

Plasma atomisation is a fascinating and highly technical process that transforms metal into fine powder using plasma torches. This article delves deep into the science

Electrode Induction Melting Inert Gas Atomisation

Overview Electrode Induction Melting Inert Gas Atomisation (EIGA) is a cutting-edge process used to produce high-quality metal powders. This technique, known for its precision and

Inert Gas Atomisation

In the ever-evolving world of metallurgy and material science, the production of high-quality metal powders is crucial for various advanced manufacturing processes. One method that

Vacuum Induction Melting

Overview of Vacuum Induction Melting Vacuum induction melting (VIM) is a sophisticated and essential process in the metallurgy industry, used primarily to produce high-quality metal

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731