Blog

all colletions

Gas Turbine Atomizing Air Systems

Imagine a fire-breathing dragon, its immense power fueled by a precise mixture of air and fuel. In the world of gas turbines, achieving optimal combustion efficiency relies on a similar principle, but with a much more meticulous approach. Enter the gas turbine atomizing air system, the unsung hero ensuring a

Gas Atomizer Equipment

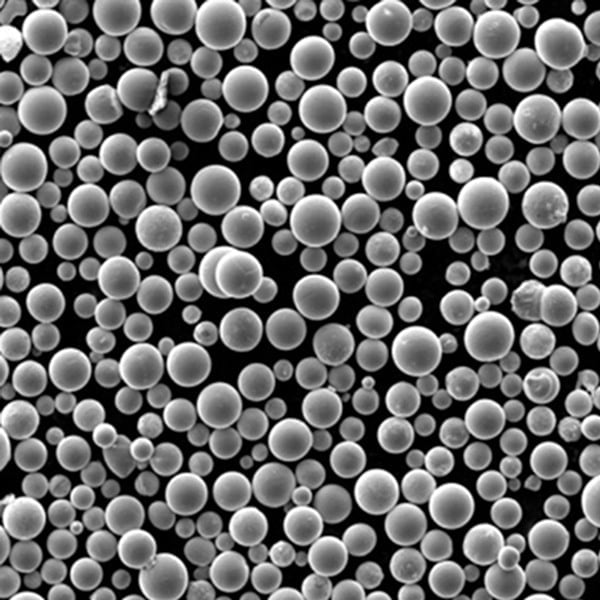

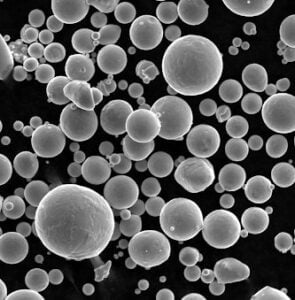

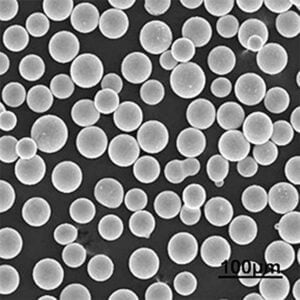

Gas atomizer equipment is a vital component in the production of high-quality metal powders used across various industries, including aerospace, automotive, medical, and electronics. This equipment utilizes high-pressure gas streams to atomize molten metal, creating fine, uniform particles that can be used in a range of applications, from additive manufacturing

Gas Atomizer Manufacturer

Overview The manufacturing world is abuzz with innovations, and gas atomization is at the forefront, especially in the production of metal powders. But what exactly does a gas atomizer manufacturer do? Simply put, these manufacturers specialize in the creation of metal powders using gas atomization—a process where molten metal is

Gas Atomizer Machines

Gas atomizer machines are crucial in various industries for creating fine metal powders, essential for applications like 3D printing, pharmaceuticals, and aerospace. If you’re delving into the world of metal powders and gas atomization, this guide is your comprehensive resource. Overview of Gas Atomizer Machines Gas atomizer machines use high-pressure

Understanding Plasma Gas Atomizers

Plasma gas atomizers play a crucial role in the production of high-quality metal powders used in various industries, from aerospace to medical implants. This guide will take you through the intricacies of plasma gas atomizers, their applications, advantages, and limitations, as well as provide detailed information about specific metal powder

Gas Atomizer for Metal Powder Production

Overview of Gas Atomizer for Metal Powder Production Metal powder production is a critical process in modern manufacturing, enabling the creation of advanced materials for a variety of applications. One of the most efficient methods for producing high-quality metal powders is through gas atomization. But what exactly is gas atomization?

Gas Turbine Atomizing Air Systems

Imagine a fire-breathing dragon, its immense power fueled by a precise mixture of air and fuel. In the world of gas turbines, achieving optimal combustion

Gas Atomizer Equipment

Gas atomizer equipment is a vital component in the production of high-quality metal powders used across various industries, including aerospace, automotive, medical, and electronics. This

Gas Atomizer Manufacturer

Overview The manufacturing world is abuzz with innovations, and gas atomization is at the forefront, especially in the production of metal powders. But what exactly

Gas Atomizer Machines

Gas atomizer machines are crucial in various industries for creating fine metal powders, essential for applications like 3D printing, pharmaceuticals, and aerospace. If you’re delving

Understanding Plasma Gas Atomizers

Plasma gas atomizers play a crucial role in the production of high-quality metal powders used in various industries, from aerospace to medical implants. This guide

Gas Atomizer for Metal Powder Production

Overview of Gas Atomizer for Metal Powder Production Metal powder production is a critical process in modern manufacturing, enabling the creation of advanced materials for

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731