Blog

all colletions

FeSiCr powder for Network System

In the ever-evolving world of network systems, ensuring reliable power delivery is paramount. Data centers, communication hubs, and critical infrastructure all rely on uninterrupted electricity flow to function. This is where FeSiCr, a powerful alloy composed of iron (Fe), silicon (Si), and chromium (Cr), steps onto the scene. But what

MS1(1.2709) Metal Powder

Metal injection molding (MIM) has revolutionized the manufacturing industry, enabling the creation of complex, near-net-shape metal parts with exceptional precision and detail. But this transformative technology relies heavily on a crucial ingredient: metal powder. And when it comes to MIM, MS1(1.2709) Metal Powder stands out as a champion, offering a

304L Stainless Steel Powder in AM

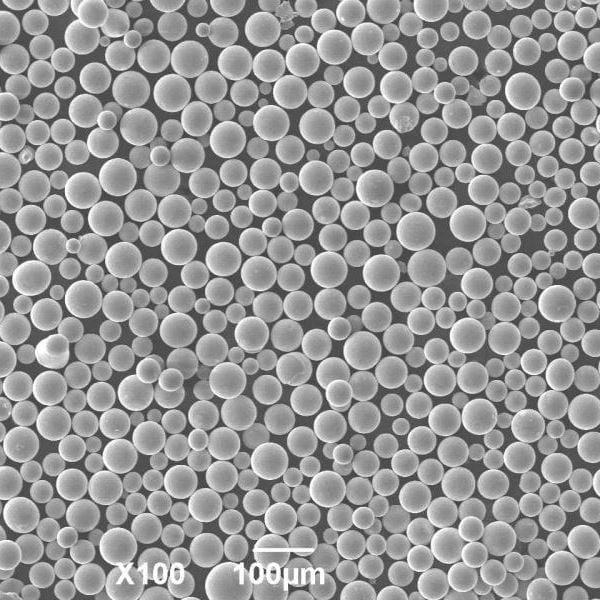

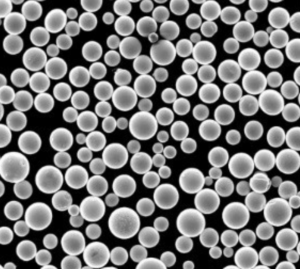

Additive manufacturing (AM), also known as 3D printing, has revolutionized the way we design and produce parts. This technology allows for the creation of complex geometries with incredible precision, opening doors for innovation across various industries. But what fuels this revolution? Enter metal powders – the building blocks of AM

17-4PH stainless steel powder

Imagine building a component that needs to be incredibly strong, resistant to corrosion, and lightweight all at the same time. Sounds like a tall order, right? Well, for those in the additive manufacturing (AM) world, this dream becomes a reality with the introduction of 17-4PH stainless steel powder specifically designed

316L Powder for MIM

Metal Injection Molding (MIM) has revolutionized the manufacturing landscape for complex, near-net-shape components. Imagine this: intricate parts with exceptional strength, corrosion resistance, and intricate details – all produced in high volumes and at a competitive cost. That’s the magic of MIM. But at the heart of this process lies a

Magic 3D Printing: LPBF process

Have you ever dreamt of building complex metal objects layer by layer, with nothing but a laser and some metal powder? Well, that’s the magic of LPBF process, a revolutionary 3D printing technology that’s transforming the manufacturing landscape. Imagine the possibilities: crafting intricate medical implants, designing lightweight aerospace components, or

FeSiCr powder for Network System

In the ever-evolving world of network systems, ensuring reliable power delivery is paramount. Data centers, communication hubs, and critical infrastructure all rely on uninterrupted electricity

MS1(1.2709) Metal Powder

Metal injection molding (MIM) has revolutionized the manufacturing industry, enabling the creation of complex, near-net-shape metal parts with exceptional precision and detail. But this transformative

304L Stainless Steel Powder in AM

Additive manufacturing (AM), also known as 3D printing, has revolutionized the way we design and produce parts. This technology allows for the creation of complex

17-4PH stainless steel powder

Imagine building a component that needs to be incredibly strong, resistant to corrosion, and lightweight all at the same time. Sounds like a tall order,

316L Powder for MIM

Metal Injection Molding (MIM) has revolutionized the manufacturing landscape for complex, near-net-shape components. Imagine this: intricate parts with exceptional strength, corrosion resistance, and intricate details

Magic 3D Printing: LPBF process

Have you ever dreamt of building complex metal objects layer by layer, with nothing but a laser and some metal powder? Well, that’s the magic

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731