Blog

all colletions

3D Printed Shock Mounts for Lightweight Automotive Applications

Revolutionizing Automotive Performance: An Introduction to 3D Printed Shock Tower Mounts The relentless pursuit of performance, efficiency, and innovation defines the modern automotive industry. Engineers and designers constantly seek new materials, manufacturing processes, and design philosophies to push boundaries. From enhancing fuel economy and electric vehicle (EV) range to improving

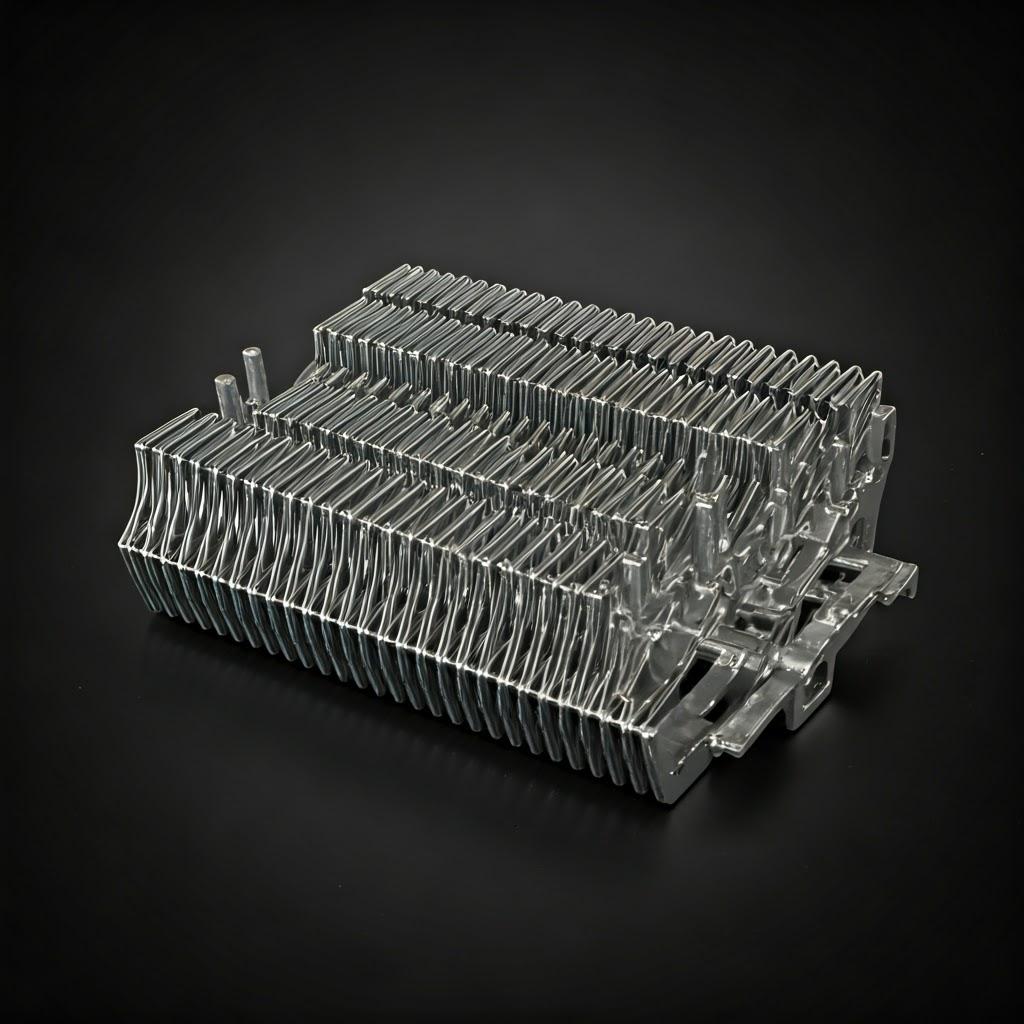

Custom Heat Sinks for Power Modules via Metal AM

Introduction: Revolutionizing Thermal Management with Custom 3D Printed Heat Sinks for Power Electronics The relentless drive towards higher power densities, miniaturization, and increased efficiency in power electronics across industries like automotive, aerospace, and industrial automation presents a significant challenge: effective thermal management. As components shrink and power throughput increases, dissipating

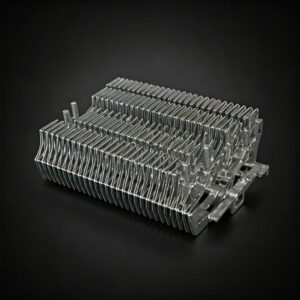

High-Efficiency Cooling Fins via Metal 3D Printing

Introduction: Enhancing Thermal Management with 3D Printed Cooling Fins In countless industrial applications, effective thermal management isn’t just a desirable feature – it’s a critical necessity. From high-performance computing and power electronics to automotive engines and aerospace systems, the ability to efficiently dissipate heat is paramount for reliability, performance, and

Additive Manufacturing of Guidance System Housings

Revolutionizing Defense: Additive Manufacturing of Missile Guidance System Housings The landscape of modern defense and aerospace technology is characterized by a relentless pursuit of higher performance, reduced weight, increased complexity, and faster development cycles. In this demanding environment, the components that make up critical systems, such as missiles, are under

3D Printed Gimbal Frames for Aerospace Optical Systems

Introduction: Revolutionizing Aerospace Optics with 3D Printed Gimbal Frames The aerospace industry operates at the pinnacle of engineering, demanding components that meet stringent requirements for performance, reliability, and weight. Within this demanding sector, optical systems used for imaging, targeting, communication, and surveillance rely heavily on the stability and precision provided

3D Printed Exhaust Manifolds for Marine Engines

The relentless pursuit of performance, efficiency, and reliability in the marine industry demands continuous innovation in design and manufacturing. From high-speed racing boats cutting through waves to robust commercial vessels navigating global trade routes, every component plays a critical role. Among these, the exhaust manifold, often subjected to extreme temperatures,

3D Printed Shock Mounts for Lightweight Automotive Applications

Revolutionizing Automotive Performance: An Introduction to 3D Printed Shock Tower Mounts The relentless pursuit of performance, efficiency, and innovation defines the modern automotive industry. Engineers

Custom Heat Sinks for Power Modules via Metal AM

Introduction: Revolutionizing Thermal Management with Custom 3D Printed Heat Sinks for Power Electronics The relentless drive towards higher power densities, miniaturization, and increased efficiency in

High-Efficiency Cooling Fins via Metal 3D Printing

Introduction: Enhancing Thermal Management with 3D Printed Cooling Fins In countless industrial applications, effective thermal management isn’t just a desirable feature – it’s a critical

Additive Manufacturing of Guidance System Housings

Revolutionizing Defense: Additive Manufacturing of Missile Guidance System Housings The landscape of modern defense and aerospace technology is characterized by a relentless pursuit of higher

3D Printed Gimbal Frames for Aerospace Optical Systems

Introduction: Revolutionizing Aerospace Optics with 3D Printed Gimbal Frames The aerospace industry operates at the pinnacle of engineering, demanding components that meet stringent requirements for

3D Printed Exhaust Manifolds for Marine Engines

The relentless pursuit of performance, efficiency, and reliability in the marine industry demands continuous innovation in design and manufacturing. From high-speed racing boats cutting through

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731