Application of DED in the aerospace field

Table of Contents

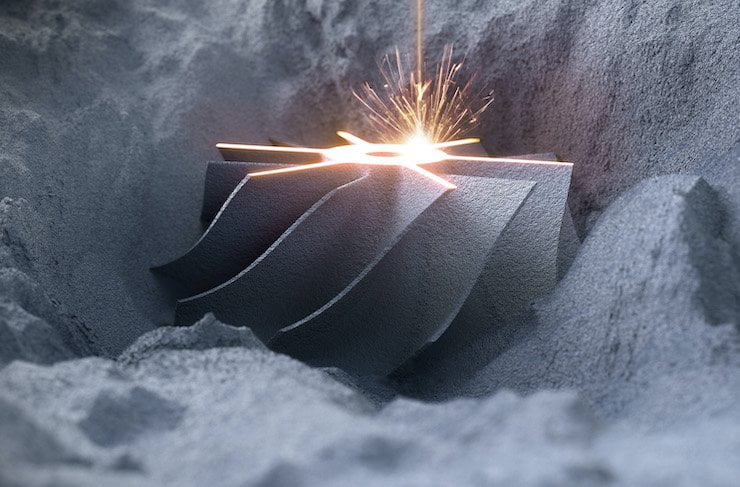

Imagine a world where complex aircraft components can be built layer by layer, on-demand, with minimal waste. This isn’t science fiction; it’s the reality of Directed Energy Deposition (DED), a cutting-edge additive manufacturing (AM) technology rapidly transforming the aerospace industry.

DED, also known as Laser Engineered Net Shaping (LENS), utilizes a focused energy source, like a laser or electron beam, to melt and deposit metallic powder, meticulously building a three-dimensional object. Think of it like a high-tech 3D printer for metal, offering unparalleled design freedom and customization for aerospace applications.

But how exactly is DED taking the aerospace industry by storm? Buckle up, as we delve into the fascinating world of DED applications, explore the diverse metal powders used, and answer some burning questions about this revolutionary technology.

DED: A Game Changer for Aerospace Manufacturing

Traditionally, aerospace components were crafted through conventional methods like casting, forging, and machining. These processes often result in significant material waste and limitations in design complexity. DED disrupts this paradigm by offering a multitude of advantages:

- Lightweighting: DED allows for the creation of intricate, hollow structures, significantly reducing weight – a critical factor for fuel efficiency and payload capacity in aircraft.

- Design Freedom: Unconstrained by traditional manufacturing limitations, DED enables the creation of complex geometries with internal channels and lattices, optimizing performance and weight distribution.

- Rapid Prototyping: DED allows for rapid fabrication of prototypes, accelerating the design and development cycle for new aerospace components.

- On-Demand Manufacturing: DED facilitates the creation of spare parts at the point of need, reducing dependence on pre-manufactured components and minimizing downtime.

- Material Efficiency: DED utilizes a near-net-shape approach, minimizing material waste compared to traditional methods.

- Repair and Restoration: DED can be used to repair damaged components, extending their lifespan and reducing the need for expensive replacements.

These benefits translate to a range of exciting applications in the aerospace field:

- Manufacturing Aircraft Engine Components: DED is making waves in the production of complex engine components like turbine blades, combustors, and heat exchangers. DED allows for the creation of components with advanced internal cooling channels, enhancing efficiency and performance.

- DED for Aircraft Fuselage and Other Structural Components: DED’s ability to create lightweight, high-strength structures makes it ideal for manufacturing aircraft fuselage sections, landing gear components, and other structural elements.

- Customization and Repair: DED empowers on-demand customization of aircraft parts, allowing for modifications to meet specific mission requirements. Additionally, DED can be used for in-situ repair of damaged components, reducing maintenance downtime and costs.

Metal Powders: The Building Blocks of DED Success

The success of DED hinges on the specific metal powders used. These powders, with precisely controlled size and morphology (shape), play a crucial role in the quality and performance of the final product. Here’s a peek at some of the most common metal powders employed in aerospace DED applications:

| **Metal Powder | Description | Properties |

|---|---|---|

| Inconel 625 | A versatile nickel-chromium-based superalloy known for its exceptional high-temperature strength, oxidation resistance, and good weldability. | Offers excellent mechanical properties at elevated temperatures, making it ideal for turbine blades, combustors, and other hot-section components. |

| Titanium 6Al-4V | A high-strength, low-weight titanium alloy widely used in the aerospace industry. | Provides a good balance of strength, ductility, and weight savings, making it suitable for airframe components, landing gear parts, and engine mounts. |

| Aluminum Alloys | A family of lightweight aluminum alloys with varying properties depending on specific composition. | Offer excellent strength-to-weight ratio and good corrosion resistance, making them suitable for non-critical structural components and lightweight enclosures. |

| Stainless Steel 316L | A versatile austenitic stainless steel known for its excellent corrosion resistance. | Offers good mechanical properties and resistance to corrosion, making it suitable for various applications like fluid handling components and non-structural parts. |

| Inconel 718 | A precipitation-hardening nickel-chromium-based superalloy with high strength and good machinability. | Offers a combination of high strength, good corrosion resistance, and excellent machinability, making it ideal for various structural components and high-pressure applications. |

| Maraging Steel | A family of high-strength, low-alloy steels with excellent toughness and dimensional stability. | Provides exceptional strength and toughness, making them suitable for landing gear components and highly stressed structural elements. |

| Nickel Alloys | A broad category of nickel-based alloys with diverse properties depending on specific composition. | Offer a wide range of properties, including high-temperature strength, corrosion resistance, and wear resistance, making them suitable for various engine components and high-wear applications. |

| Cobalt-Chrome Alloys | A family of cobalt-chromium alloys known for their high wear resistance and biocompatibility. | Offer exceptional wear resistance and good biocompatibility, making them ideal for applications like jet engine bearings and biomedical implants (although DED applications in biomedicine fall outside the scope of this article). |

| Copper Alloys | A family of copper alloys with varying properties depending on specific composition. | Offer high electrical conductivity and good thermal conductivity, making them suitable for heat exchangers and electrical components. |

| Refractory Metals | A group of high-melting-point metals like tungsten, tantalum, and molybdenum. | Possess exceptional high-temperature strength and resistance to harsh environments, making them suitable for applications like rocket engine nozzles and re-entry vehicles. |

It’s important to note that this is not an exhaustive list, and ongoing research is constantly developing new and improved metal powders specifically tailored for DED applications. The selection of the optimal metal powder depends on various factors like the desired final properties of the component, operational environment, and cost considerations.

Advantages and Limitations of DED

While DED offers a plethora of advantages for the aerospace industry, it’s not without its limitations. Here’s a balanced view of both sides of the coin:

Advantages:

- Design Freedom: As mentioned earlier, DED unlocks a world of design possibilities, enabling the creation of complex geometries previously unimaginable with traditional techniques.

- Lightweighting: The ability to create hollow structures with internal lattices translates to significant weight savings, a critical factor for aircraft performance.

- Reduced Waste: DED utilizes a near-net-shape approach, minimizing material waste compared to traditional methods.

- Rapid Prototyping: DED facilitates the rapid creation of prototypes, accelerating the design and development cycle for new aerospace components.

- On-Demand Manufacturing: DED empowers on-demand production of spare parts, reducing dependence on pre-manufactured components and minimizing downtime.

- Repair and Restoration: DED can be used to repair damaged components, extending their lifespan and reducing the need for expensive replacements.

Limitations:

- Build Time: While faster than traditional methods, DED can still be a relatively slow process compared to some subtractive techniques, especially for larger components.

- Surface Finish: DED-built components often require additional post-processing steps to achieve a desired surface finish.

- Material Availability: The availability of certain metal powders, particularly high-performance alloys, can be limited and expensive.

- Process Control: DED is a complex process that requires careful control over parameters like laser power, scan speed, and powder feed rate to ensure consistent quality and avoid defects.

- Qualification and Certification: DED components require rigorous testing and certification to meet stringent aerospace safety standards.

The Future of DED in Aerospace

Despite these limitations, the future of DED in aerospace is bright. As technology advances, build times will decrease, surface quality will improve, and the availability of high-performance metal powders will increase. Additionally, ongoing research is focused on developing new DED techniques like multi-material printing and in-situ process monitoring, further expanding its capabilities.

The potential impact of DED on the aerospace industry is vast. It can revolutionize the design and manufacturing of aircraft, leading to lighter, more efficient, and more cost-effective vehicles. Furthermore, DED can enable on-demand repairs in the field, reducing maintenance downtime and improving operational readiness.

FAQs

Here are some frequently asked questions about DED in the aerospace industry, presented in a table format for easy reference:

| Question | Answer |

|---|---|

| What are the main benefits of using DED in aerospace applications? | DED offers design freedom, lightweighting, reduced waste, rapid prototyping, on-demand manufacturing, and repair capabilities. |

| What are some of the challenges associated with DED? | Build time, surface finish, material availability, process control, and qualification for aerospace applications are some of the key limitations. |

| What are the most common metal powders used in DED for aerospace? | Inconel 625, Titanium 6Al-4V, Aluminum Alloys, Stainless Steel 316L, Inconel 718, Maraging Steel, Nickel Alloys, Cobalt-Chrome Alloys, Copper Alloys, and Refractory Metals are some of the prominent choices. |

| How will DED impact the future of aerospace manufacturing? | DED has the potential to revolutionize aerospace manufacturing by enabling the creation of lighter, more efficient, and more cost-effective aircraft. On-demand repairs and reduced downtime are additional benefits. |

| Is DED a mature technology for aerospace applications? | DED is still under development, but it’s rapidly maturing. Ongoing research is addressing limitations like build time and surface finish. |

| What are some of the biggest hurdles to wider adoption of DED in aerospace? | Qualification and certification of DED components for flight use is a significant hurdle. Additionally, broader availability of high-performance metal powders at competitive prices is needed. |

| Can DED be used for repairs outside of controlled environments? | Research is ongoing for mobile DED systems that could enable repairs in the field. However, such technology is still in its early stages. |

The Human Element: Why DED Matters

Beyond the technical advancements, DED represents a shift in the way we think about aerospace manufacturing. It empowers a more agile and responsive approach, fostering innovation and customization. Imagine a world where spare parts can be printed on-demand at remote locations, or damaged components can be repaired in the field, minimizing downtime and maximizing operational efficiency. This not only translates to cost savings but also enhances safety and mission readiness.

The story of DED in aerospace is not just about technology; it’s about the human ingenuity and problem-solving spirit that drives advancements. It’s about pushing the boundaries of what’s possible and creating a future where air travel is not only faster and more efficient but also lighter on the environment. As DED continues to evolve, one thing is certain: the sky’s the limit for its potential impact on the aerospace industry.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731