Energy-Efficient Additive Manufacturing in Los Angeles: A Sustainable Shift for Industrial Buyers & Distributors

Table of Contents

1. Introduction: The Rise of Energy-Efficient Additive Manufacturing in Los Angeles

Additive manufacturing (AM), widely known as 3D printing, has transformed from a prototyping tool into a full-scale manufacturing solution—especially for industries like aerospace, medical devices, and automotive. However, as global industries push toward net-zero goals, energy consumption has emerged as a top concern for industrial producers and buyers alike.

In recent years, energy-efficient additive manufacturing has gained traction as a sustainable alternative to traditional subtractive methods. Particularly in innovation hubs like Los Angeles, this shift is not just about technological advancement—it’s about environmental responsibility and regulatory compliance.

Why Energy Efficiency Matters in B2B Manufacturing

For wholesale buyers, distributors, and industrial suppliers, energy efficiency isn’t just a buzzword—it’s a strategic advantage. Here’s why:

- Lower Operating Costs: Energy-efficient 3D printers reduce electricity usage over time, translating to lower production expenses.

- Regulatory Compliance: California’s strict energy and emissions regulations encourage the use of eco-friendly technologies.

- Brand Reputation: B2B companies that prioritize sustainability enhance their brand image to clients and investors.

- Material Optimization: Additive manufacturing enables near-zero waste production, especially when using recyclable metal powders.

Why Los Angeles Is Leading the Way

Los Angeles has become a hotbed for sustainable manufacturing innovation due to its:

- High concentration of aerospace, biotech, and automotive industries that demand precision and efficiency

- State incentives and grants encouraging green manufacturing

- Access to cutting-edge R&D institutions and tech-forward supply chains

As a result, energy-efficient additive manufacturing in Los Angeles is not just a trend—it’s a competitive necessity.

2. Market Trends: The Growth of Sustainable 3D Printing Technologies

The market for sustainable and energy-efficient 3D printing solutions is expanding rapidly, driven by both demand-side and policy-side factors. Here’s a closer look at the trends shaping this space.

Global and Regional Market Insights

| Region | Market Size (2023) | CAGR (2023–2030) | Key Drivers |

|---|---|---|---|

| North America | $4.9B | 18.2% | Aerospace, defense, medical device growth |

| Europe | $3.8B | 17.5% | EU Green Deal, energy regulations |

| Asia-Pacific | $5.2B | 20.1% | Rapid industrialization, R&D expansion |

📈 According to industry reports, the global metal additive manufacturing market is projected to reach over $25 billion by 2030, with a strong emphasis on energy-efficient systems.

Key Industry Sectors Driving Demand

- Aerospace: Lightweight, high-strength parts with minimal waste

- Medical Devices: Customized implants and surgical tools with reduced production emissions

- Electric Vehicles (EVs): Complex geometries and heat-efficient components produced with less energy

- Defense & Space: Mission-critical parts built quickly, reliably, and sustainably

California’s Role in Green Manufacturing

California’s stringent emissions standards and clean energy incentives make Los Angeles a prime location for sustainable AM:

- SB 100: Mandates 100% clean electricity by 2045

- Low Carbon Fuel Standard (LCFS): Encourages low-emission industrial processes

- Advanced Manufacturing Tax Credit: Provides rebates for energy-efficient systems

These policies have accelerated the adoption of energy-efficient 3D printing technologies across the state.

3. Key Considerations When Sourcing Energy-Efficient 3D Printing Solutions

For distributors, supply chain managers, and wholesale buyers, selecting the right additive manufacturing solution requires a comprehensive understanding of energy efficiency metrics and supplier capabilities.

Here are the most important factors to evaluate when sourcing energy-efficient 3D printing technology:

🧠 Technical Considerations

| Factor | Description |

|---|---|

| Energy Consumption (kWh) | Measure average power draw per build cycle |

| Powder Reusability | Ability to reuse unused metal powder reduces waste and cost |

| Build Speed vs. Efficiency | Fast builds must still maintain low energy input per part |

| Layer Resolution | High resolution at low energy = better sustainability + precision |

| Printer Cooling Systems | Efficient thermal management reduces overall power usage |

✅ Supplier Qualities to Look For

- Transparency in Energy Usage: Energy usage data per build or per kg of material

- Lifecycle Assessments: Suppliers that provide full LCA reports on powder and equipment

- Certifications: ISO 50001 (Energy Management), ASTM F3122, and RoHS compliance

- Material Efficiency Claims: Verified claims of near-zero material waste

- On-site Support and Training: Training for energy-efficient operation and maintenance

🔎 Checklist for B2B Buyers

- Does the supplier provide energy consumption data for each printer model?

- Are the metal powders optimized for reuse and recyclability?

- What is the average energy consumption per part or kilogram?

- Are there engineering teams available to optimize builds for low energy use?

- Can the supplier help meet California’s energy efficiency regulations?

🏭 How Metal3DP Supports Energy-Efficient Manufacturing

Metal3DP is a trusted provider of industrial-grade additive manufacturing solutions with a strong emphasis on sustainability and energy optimization. Here’s how Metal3DP empowers clients:

- Efficient SEBM Printers: Scanning Electron Beam Melting (SEBM) technology offers energy savings compared to traditional PBF methods.

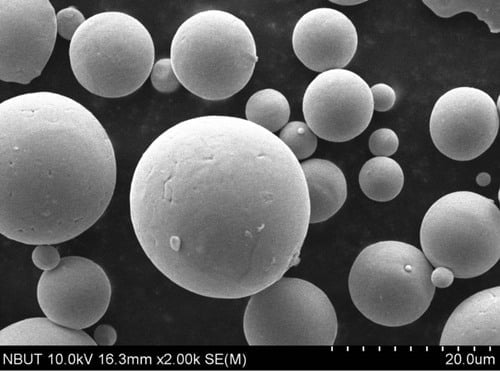

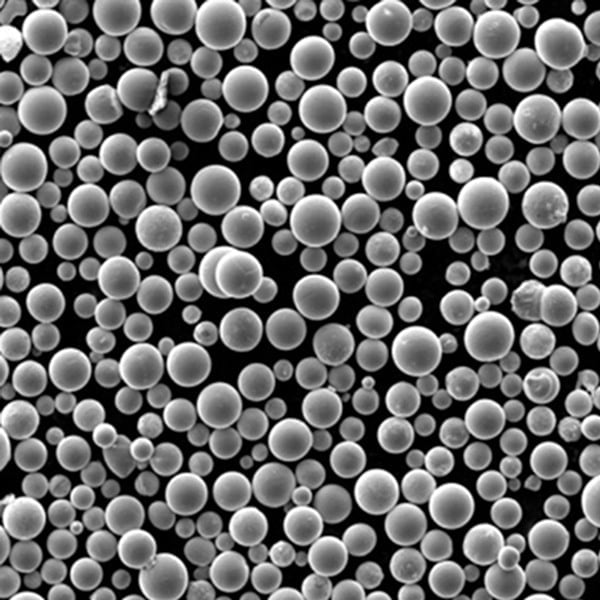

- High-Performance Metal Powders: Manufactured using advanced gas atomization systems that ensure excellent flowability and minimal waste.

- Powder Reusability: Metal3DP powders are designed for high recyclability, reducing material costs and environmental impact.

- Lifecycle Support: The company provides energy-use data, recycling programs, and operator training for energy-conscious production.

Metal3DP’s commitment to innovation and sustainability makes it a preferred partner for clients looking to align their operations with both performance and environmental standards.

4. Top 5 Energy-Efficient Additive Manufacturing Suppliers in Los Angeles

Los Angeles is home to a growing number of additive manufacturing companies that prioritize energy efficiency and sustainable production. For B2B buyers, selecting the right supplier is crucial for meeting both production demands and environmental goals.

Here are the top 5 suppliers offering energy-efficient additive manufacturing solutions in the Los Angeles region:

🏆 Top 5 Suppliers Comparison Table

| Company Name | Specialties | Energy-Efficient Tech | Industries Served | Certifications |

|---|---|---|---|---|

| Metal3DP | SEBM printers, metal powders | ✅ SEBM, gas atomization | Aerospace, medical, automotive | ISO, RoHS, ASTM |

| Carbon3D | Polymer additive manufacturing | ✅ DLS (Digital Light Synthesis) | Footwear, dental, automotive | ISO 14001, FDA |

| Relativity Space | Large-scale AM for rockets | ✅ Stargate metal printer | Aerospace | Custom certification |

| Morf3D (a Nikon Company) | Aerospace parts, DMLS printing | ✅ Precision metal AM | Aerospace, defense | AS9100D, ISO 13485 |

| Divergent Technologies | Automotive chassis, parts | ✅ Sustainable AM lines | Automotive, EVs | ISO 9001 |

🌿 All of these companies are known for adopting low-energy systems, optimizing build processes, and reducing material waste.

Supplier Profiles

1. Metal3DP

- Specializes in metal 3D printers and spherical powders using energy-efficient SEBM and gas atomization technologies.

- Offers high sphericity powders that minimize build energy and maximize recyclability.

- Provides full lifecycle support, including sustainability consulting and energy use reporting.

2. Carbon3D

- Known for its proprietary DLS technology, which reduces print times and energy usage.

- Focuses on polymer-based applications but maintains a strong presence in high-volume production.

3. Relativity Space

- Uses large-scale 3D printing to build entire rockets, reducing part count and energy-intensive machining.

- Pioneers a sustainable approach in aerospace manufacturing.

4. Morf3D

- Precision engineering for aerospace clients.

- Implements energy monitoring and optimization strategies in all builds.

5. Divergent Technologies

- Manufactures 3D-printed automotive frames and components.

- Focuses on reducing emissions and resource usage in EV production.

These suppliers reflect the region’s commitment to sustainable innovation, making Los Angeles a strategic location for environmentally-conscious procurement.

5. Why More Wholesale Buyers Are Switching to Metal 3D Printing for Sustainability

Metal 3D printing, especially using energy-efficient technologies, is rapidly becoming the preferred choice for wholesale buyers and industrial distributors. Here’s why:

🌍 Environmental Benefits of Metal Additive Manufacturing

| Sustainability Benefit | Impact |

|---|---|

| Reduced Material Waste | Near-net shape production minimizes scrap |

| Lower Energy Usage | Optimized build parameters reduce kWh per part |

| Recyclable Powders | Unused powder is recycled for future builds |

| Lightweighting | Lighter parts improve fuel efficiency in aerospace & EVs |

| On-Demand Manufacturing | Eliminates overproduction and inventory waste |

💼 B2B Advantages for Wholesale Buyers

- Lower Total Cost of Ownership (TCO): Less energy and less waste = lower production costs over time

- Sustainable Supply Chains: Metal AM supports localized, just-in-time manufacturing strategies

- Improved ROI: Durable parts with longer lifespans and precision tolerances

- Compliance Ready: Meets environmental certifications and reporting requirements

🔩 Key Materials Driving the Shift

| Metal Alloy | Sustainability Feature | Applications |

|---|---|---|

| Ti6Al4V | Lightweight, recyclable, corrosion-resistant | Aerospace, medical implants |

| CoCrMo | Biocompatible and durable | Orthopedic, dental |

| Stainless Steel | Fully recyclable, low cost | Automotive, tooling |

| Superalloys | High strength, high temperature resistance | Turbines, propulsion systems |

These materials are often produced using advanced powder-making systems like gas atomization and PREP, ensuring optimal sphericity and flowability while minimizing waste.

📦 Ideal for Distributors and OEMs

- Energy-efficient metal AM is scalable and ideal for both small-batch and high-volume production.

- Distributors can offer eco-friendly alternatives to clients seeking sustainable product lines.

- OEMs benefit from design freedom, reduced lead times, and energy savings.

Additive manufacturing is no longer just an R&D tool—it is a strategic imperative for sustainable production.

6. Why Choose Metal3DP as Your Energy-Efficient Additive Manufacturing Partner

Metal3DP stands out as a global leader in energy-efficient additive manufacturing systems and metal powders. Headquartered in Qingdao, China, and supporting clients worldwide—including Los Angeles—Metal3DP provides complete AM solutions built for sustainability and performance.

⚙️ What Makes Metal3DP Different?

| Feature | Benefit to B2B Buyers |

|---|---|

| SEBM Technology | Lower energy consumption per part compared to traditional PBF |

| Advanced Powder Production | Gas atomization & PREP ensure high sphericity and flowability |

| Diverse Powder Portfolio | Includes TiNi, TiTa, TiAl, CoCrMo, Stainless Steel, Superalloys |

| Recyclable Materials | Optimized for powder reuse, reducing waste and cost |

| Lifecycle Support | Training, data reporting, and consulting for energy-efficient builds |

🔗 Learn more about Metal3DP’s sustainability-driven approach and commitment to clean manufacturing.

🌟 Trusted by Industry Leaders

Metal3DP’s systems are used by leading players in:

- Aerospace: Mission-critical components with tight tolerances

- Medical: Biocompatible implants produced with minimal waste

- Automotive: Lightweight, strong parts for EVs and performance vehicles

📈 Scalable Solutions for Distributors and OEMs

- Printer Customization: Tailored build volumes and specifications

- Bulk Powder Supply: Ongoing supply agreements available for distributors

- Support Services: Application development, training, and energy audits

🔗 Internal Link for Buyers

If you’re sourcing high-quality, energy-efficient additive manufacturing solutions for your business, explore Metal3DP’s product catalog for industrial printers and powders tailored to your application.

7. How to Order Wholesale Energy-Efficient 3D Printing Solutions from Metal3DP

Metal3DP offers a streamlined and customer-centric wholesale ordering process for energy-efficient 3D printing systems and metal powders. Whether you are a distributor, OEM, or industrial buyer in the U.S., especially in Los Angeles, Metal3DP simplifies the procurement journey while ensuring product quality and compliance.

📦 Step-by-Step Wholesale Ordering Process

| Step | Description |

|---|---|

| 1 | Consultation & Needs Assessment: Define your application, materials, and volume requirements. |

| 2 | Quote Request: Submit specifications for a customized quote. |

| 3 | Sample Evaluation (Optional): Request sample prints or powder analysis. |

| 4 | Order Confirmation: Confirm product specs, delivery timeline, and pricing. |

| 5 | Production & Shipping: Metal3DP manufactures and delivers to your site. |

| 6 | Post-Sales Support: Includes training, maintenance, and powder recycling guidance. |

📞 Distributors and OEMs can request a direct consultation with Metal3DP’s technical team to evaluate your production goals and develop a tailored AM solution.

📄 Documentation Provided with Orders

When you place an order with Metal3DP, you receive:

- Certificate of Analysis (CoA) for metal powders

- Energy usage reports for AM systems

- User manuals and setup guides

- Compliance documentation (RoHS, ASTM, ISO)

🌐 Logistics & International Support

Metal3DP ships globally with dedicated logistics support for U.S. clients:

- Fast delivery to Los Angeles and the West Coast via air or sea freight

- Import/export documentation assistance

- On-site or remote installation support available upon request

Explore the full range of available printers and metal powders by visiting the Metal3DP product library.

8. Case Study: Real-World Applications of Sustainable 3D Printing in Los Angeles

To illustrate the impact of energy-efficient additive manufacturing, let’s look at real-world examples of how businesses in Los Angeles are applying Metal3DP’s technology for sustainable production.

🏭 Case Study 1: Aerospace Component Manufacturer

Company: Confidential Tier-1 Aerospace Supplier

Location: Los Angeles County

Challenge: Reduce energy use and scrap material in titanium part production

Solution: Adopted Metal3DP SEBM printer and Ti6Al4V powder

Results:

- 32% reduction in energy consumption per part

- 95% powder recyclability rate

- Achieved AS9100 compliance for aerospace parts

Internal link: Learn more about Metal3DP’s additive manufacturing process and how it ensures energy-efficient builds for critical components.

🏥 Case Study 2: Orthopedic Device Manufacturer

Company: Medical Device OEM

Location: Orange County, CA (Greater LA Area)

Challenge: Manufacture biocompatible implants with minimal energy and waste

Solution: Used CoCrMo alloy powder and Metal3DP’s customized SEBM printer

Results:

- 24% energy savings over traditional CNC machining

- Reduced lead time by 40%

- Passed ISO 13485 certification for medical devices

🚗 Case Study 3: Electric Vehicle Startup

Company: EV Chassis Developer

Location: Downtown Los Angeles

Challenge: Produce lightweight, structurally sound brackets and chassis parts

Solution: Utilized Metal3DP’s TiAl alloy and SEBM process

Results:

- 28% weight reduction in parts

- 20% total energy reduction per production cycle

- Enabled on-demand manufacturing with just-in-time delivery model

These examples highlight the versatility and efficiency of Metal3DP’s solutions across high-impact industries in the Los Angeles region.

9. FAQs: Common Questions About Energy-Efficient Additive Manufacturing

❓ What makes a 3D printing system energy-efficient?

Several factors determine energy efficiency, including:

- Low energy consumption per layer or per part

- Efficient thermal control systems

- Recyclable materials that reduce the need for raw input

- Optimized software for reduced build time

Metal3DP’s SEBM printers are engineered for low kWh consumption while maintaining high precision.

❓ How does metal additive manufacturing compare to traditional manufacturing in terms of energy use?

Traditional machining is subtractive—it removes material, generating waste and consuming energy in the process. In contrast, metal AM builds parts layer by layer, using only the necessary material. Metal3DP’s systems also allow for powder recycling, reducing the need for virgin material.

❓ Can Metal3DP ship to the U.S.? What support is available for American buyers?

Absolutely. Metal3DP ships globally and offers dedicated support for clients in the Los Angeles region and across the U.S. Services include:

- Logistics and customs assistance

- Remote installation support

- Training for operators and engineers

- Maintenance and powder recycling guidance

❓ What types of certifications or compliance documentation are provided?

Metal3DP provides:

- ISO 9001, ISO 13485, ASTM, and RoHS documentation

- Material traceability reports

- Energy usage documentation per build

- Regulatory compliance for California-based firms

❓ How do I get started with ordering or consultation?

You can contact Metal3DP through their official website to speak with a technical consultant, request a quote, or schedule a virtual demo. You can also view their About Us page to learn more about the company’s mission and global footprint.

✅ Conclusion & Call to Action

Energy-efficient additive manufacturing is no longer just an ideal—it’s a practical, scalable, and cost-effective solution for industrial manufacturers in Los Angeles and beyond. From reducing material waste to slashing energy bills, metal AM offers compelling advantages for B2B buyers, distributors, and OEMs.

Metal3DP stands at the forefront of this transformation, offering cutting-edge printers, high-quality metal powders, and end-to-end support tailored for sustainability. Whether you’re in aerospace, medical, or automotive sectors, Metal3DP has solutions that align with your performance and environmental goals.

👉 Ready to take the next step toward sustainable manufacturing?

Explore Metal3DP’s products and services or contact their team directly to begin your energy-efficient additive manufacturing journey today.

✅ Summary of Internal Anchor Links Used:

| Anchor Text | Linked URL |

|---|---|

| Metal3DP’s sustainability-driven approach | https://met3dp.com/about-us/ |

| metal 3D printers and spherical powders | https://met3dp.com/metal-3d-printing/ |

| Metal3DP’s additive manufacturing process | https://met3dp.com/printing-methods/ |

| Metal3DP’s product catalog | https://met3dp.com/product/ |

| official website | https://met3dp.com/ |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731