HK30 for powder metallurgy

Table of Contents

Have you ever dreamt of building complex metal parts with unmatched strength, resilience, and resistance to harsh environments? Well, stop dreaming and start exploring the wonders of HK30! This superhero material is taking the world of powder metallurgy by storm, offering a unique blend of properties that leave traditional alloys in the dust.

But what exactly is HK30 for powder metallurgy, and why is it causing such a stir? Buckle up, because we’re about to delve into the fascinating world of this metal powder and unlock its secrets.

An Overview of HK30 for Powder Metallurgy

HK30 for powder metallurgy is a superstar member of the austenitic stainless steel family. What makes it special? It’s all about the clever addition of niobium. This element acts as a stabilizer, preventing a phenomenon called chromium carbide precipitation during high-temperature applications. This translates to exceptional resistance against:

- Carburization: Imagine your metal parts slowly turning into brittle carbides when exposed to carbon-rich environments. Not with HK30! It stands strong, maintaining its integrity.

- Sulphidation: Sulfur can be a real enemy, causing metal components to deteriorate. But HK30 throws a mighty punch against sulphidation, ensuring your parts stay tough.

- Oxidation: High temperatures can turn metals into rust-like oxides. Not HK30! It boasts impressive resistance to oxidation, keeping your components in tip-top shape.

These remarkable properties make HK30 a perfect candidate for powder metallurgy, a revolutionary process that creates complex metal parts from metal powders. By utilizing HK30 powder, manufacturers can create intricate components with the exceptional characteristics we just discussed.

Key Takeaways:

- HK30 is a niobium-stabilized austenitic stainless steel powder.

- It offers outstanding resistance to carburization, sulphidation, and oxidation.

- These properties make HK30 ideal for powder metallurgy applications.

the Power of HK30 for powder metallurgy

Now, let’s get a little nerdy and explore the exact composition of HK30. Here’s a breakdown of the key players:

| Element | Weight % | Role |

|---|---|---|

| Chromium (Cr) | 18-20 | Provides excellent corrosion resistance and high-temperature strength. |

| Nickel (Ni) | 20-22 | Enhances ductility and toughness, making the material formable. |

| Carbon (C) | ≤ 0.07 | Contributes to strength and hardness. However, too much carbon can lead to brittleness, hence the low percentage. |

| Manganese (Mn) | ≤ 2.0 | Improves hardenability and counters the negative effects of sulfur. |

| Silicon (Si) | ≤ 1.0 | Improves deoxidation and casting properties. |

| Niobium (Nb) | Stabilizes the microstructure and prevents chromium carbide precipitation during high-temperature use. | |

| Iron (Fe) | Balance | Forms the base of the alloy and contributes to overall strength. |

This specific composition allows HK30 to achieve a perfect balance between strength, toughness, and resistance to harsh environments. It’s like having a superhero with both incredible physical power and an impenetrable shield!

Key Takeaways:

- HK30’s composition includes chromium, nickel, carbon, manganese, silicon, niobium, and iron.

- Each element plays a crucial role in achieving the desired properties.

- The balance between these elements makes HK30 a versatile and powerful material.

Properties and Characteristics of HK30

With its unique composition comes a set of exceptional properties that make HK30 stand out from the crowd. Here’s a closer look:

| Property | Description | Significance |

|---|---|---|

| High-Temperature Resistance | HK30 can withstand temperatures exceeding 900°C (1652°F) without losing its strength or integrity. | Perfect for applications involving hot exhaust gases, turbine components, and heat exchangers. |

| Excellent Corrosion Resistance | HK30 exhibits superior resistance to various corrosive environments, including acidic, alkaline, and salt-laden atmospheres. | Ideal for parts used in chemical processing, marine environments, and applications exposed to harsh chemicals. |

| Good Mechanical Strength | Even at elevated temperatures, HK30 maintains impressive mechanical strength, making it suitable for high-stress applications. | Well-suited for components in power generation equipment, aerospace components, and wear-resistant parts. |

| Good Ductility and Formability | Unlike some high-strength alloys, HK30 retains a good degree of ductility, allowing for shaping and forming during the manufacturing process. | This enables the creation of complex geometries using powder metallurgy |

| Good Weldability | HK30 can be welded using various techniques with minimal risk of cracking or distortion. | This facilitates the joining of complex components fabricated through powder metallurgy. |

| High Creep Resistance | Under prolonged stress at high temperatures, HK30 exhibits minimal deformation (creep). | Crucial for components in turbines, boilers, and other applications experiencing constant high-temperature loads. |

| Oxidation Resistance | HK30 forms a protective oxide layer that prevents further oxidation at elevated temperatures. | Extends the lifespan of components operating in hot, oxygen-rich environments. |

Advantages OF HK30 for powder metallurgy

Here’s where HK30 truly shines. Compared to other high-temperature alloys used in powder metallurgy, it offers some distinct advantages:

- Improved Sintering Behavior: During the powder metallurgy process, HK30 sinters (fuses together) at a lower temperature compared to some other high-temperature alloys. This translates to:

- Energy Savings: Lower sintering temperatures require less energy, making the manufacturing process more eco-friendly and cost-effective.

- Reduced Distortion: Lower sintering temperatures minimize the risk of warping or distortion in complex geometries.

- Excellent Powder Characteristics: HK30 powder boasts a good flowability and packability, crucial for achieving uniform density during powder metallurgy. This translates to:

- Dimensional Accuracy: Precise dimensional control is achievable, leading to parts with tighter tolerances.

- Improved Mechanical Properties: Uniform density ensures consistent mechanical properties throughout the component.

- Biocompatibility: For some specific grades of HK30, biocompatibility properties are observed. This opens doors for potential applications in the medical device industry.

Key Takeaways:

- HK30 boasts a unique combination of high-temperature resistance, corrosion resistance, good mechanical strength, ductility, and weldability.

- It offers superior creep resistance and oxidation resistance compared to many other powder metallurgy materials.

- HK30’s advantages include improved sintering behavior, excellent powder characteristics, and potential biocompatibility for specific grades.

Applications of HK30 in Powder Metallurgy

With its exceptional properties, HK30 unlocks a vast array of applications in diverse industries. Here are some prominent examples:

| Industry | Applications | Specific Advantages of HK30 |

|---|---|---|

| Automotive | Turbocharger housings, exhaust manifolds, valve components | High-temperature resistance, excellent corrosion resistance against exhaust fumes, good mechanical strength for handling high pressures. |

| Energy | Gas turbine components, heat exchangers, reformer tubes | Exceptional creep resistance for withstanding constant high-temperature loads, superior oxidation resistance for prolonged operation in hot environments. |

| Chemical Processing | Reactor vessels, piping systems, valves | Outstanding corrosion resistance to various chemicals, good mechanical strength for handling pressure and aggressive fluids. |

| Aerospace | Afterburner components, exhaust ducting, rocket engine parts | High-temperature resistance for withstanding extreme heat, good strength-to-weight ratio for lightweight yet robust components. |

| Medical Devices | (For specific biocompatible grades) Joint implants, surgical instruments | Potential for biocompatibility, good corrosion resistance for implants in the body. |

Beyond the Obvious: Exploring Niche Applications

The potential of HK30 extends beyond these well-established applications. Here are some exciting niche areas where HK30’s unique properties are making waves:

- Additive Manufacturing: With advancements in 3D printing technology, HK30 powder shows promise for creating complex, high-performance parts using laser melting techniques.

- Wear-Resistant Components: The combination of strength and good wear resistance makes HK30 suitable for applications like gears, bearings, and pump components.

Key Takeaways:

- HK30 finds extensive use in various industries due to its exceptional properties.

- From automotive to aerospace and chemical processing, HK30 is a game-changer for high-performance components.

- Emerging applications in additive manufacturing and wear-resistant components further highlight its versatility.

We will continue exploring HK30 in the next sections, diving deeper into its specifications, suppliers, and a balanced view of its pros and cons. Stay tuned!

Specific HK30 Metal Powders

Now that we’ve been thoroughly impressed by HK30’s capabilities, let’s get down to specifics. Here’s a breakdown of some commercially available HK30 metal powders, highlighting their key features:

1. Osprey® HK30 by Sandvik

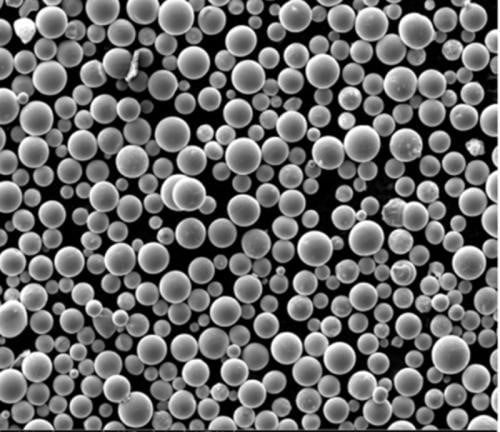

- Description: This gas-atomized powder boasts a spherical morphology, low oxygen content, and a tightly controlled particle size distribution. These characteristics contribute to excellent flowability, packability, and minimal internal stresses in the final component.

- Applications: Ideally suited for demanding applications in the automotive, aerospace, and energy sectors, particularly for components requiring high-temperature resistance, corrosion resistance, and good mechanical strength.

2. HK30 by Höganäs AB

- Description: This nitrogen-atomized powder offers a high degree of sphericity and a well-defined particle size distribution. It’s known for its excellent compactability and sintering behavior, leading to near-net-shape parts with minimal post-processing needs.

- Applications: A popular choice for applications in the automotive and energy industries, particularly for components like turbocharger housings, exhaust manifolds, and heat exchanger components.

3. AMPO® HK30 by AMETEK

- Description: This gas-atomized powder features a spherical morphology and a tightly controlled particle size distribution. AMPO® HK30 is known for its exceptional flowability and packing density, enabling the creation of complex geometries with high dimensional accuracy.

- Applications: This powder caters to diverse industries like automotive, aerospace, and chemical processing. It’s particularly well-suited for applications requiring intricate geometries and tight tolerances.

4. HK30 by AP&C

- Description: This gas-atomized powder offers a spherical morphology and a controlled particle size distribution. It exhibits good flowability and packing density, making it suitable for various powder metallurgy applications.

- Applications: A versatile option for diverse industries, including automotive, energy, and chemical processing. It’s a good choice for components requiring a balance of properties and cost-effectiveness.

5. HK30 by SHANGHAI GESER METAL POWDER CO., LTD

- Description: This gas-atomized powder boasts a spherical morphology and a controlled particle size distribution. It’s known for its good flowability and packing density, making it a cost-effective option for various powder metallurgy applications.

- Applications: A budget-friendly choice for industries like automotive and general engineering, where cost considerations play a significant role.

6. Custom HK30 Variants:

Several manufacturers offer custom HK30 variants with tailored chemistries or particle size distributions. These cater to specific application needs, such as optimizing high-temperature performance or achieving even finer surface finishes in the final component.

Key Takeaways:

- Various manufacturers offer HK30 metal powders with distinct characteristics.

- Factors like atomization method, morphology, and particle size distribution influence the powder’s performance and suitability for specific applications.

- Custom HK30 variants cater to specialized needs within different industries.

Choosing the Right HK30 Powder

While all these HK30 powders share the core benefits of the material, selecting the right one requires careful consideration. Here are some key factors to weigh:

- Application requirements: Consider the specific properties most crucial for your application (e.g., high-temperature resistance, corrosion resistance, dimensional accuracy).

- Part complexity: For intricate geometries, powders with excellent flowability and packing density are preferred.

- Cost considerations: Balance the desired properties with your budget constraints. Custom variants might offer superior performance but come at a premium.

Consulting with a reputable powder metallurgy supplier and discussing your specific needs will ensure you select the optimal HK30 powder for your project.

Strengths and Weaknesses OF HK30 for Powder Metallurgy

No material is perfect, and HK30 is no exception. Here’s a comprehensive analysis of its strengths and weaknesses:

Strengths:

- Exceptional high-temperature resistance: Withstands extreme temperatures without compromising strength or integrity.

- Outstanding corrosion resistance: Offers excellent resistance to various corrosive environments, extending component lifespan.

- Good mechanical strength: Maintains impressive strength even at elevated temperatures, suitable for high-stress applications.

- Good ductility and formability: Allows for shaping and forming during the manufacturing process, enabling complex geometries.

- Good weldability: Can be welded using various techniques with minimal risk of cracking or distortion.

- Improved sintering behavior: Sinters at lower temperatures compared to some other high-temperature alloys, leading to energy savings and reduced distortion.

- Excellent powder characteristics: Offers good flowability and packability, enabling uniform density distribution and consistent mechanical properties in the final component.

- Potential biocompatibility (for specific grades): Opens doors for applications in the medical device industry.

Weaknesses:

- Higher cost compared to some common steels: Due to its unique composition and processing requirements, HK30 can be more expensive than traditional steels.

- Limited availability of certain custom variants: Highly specialized HK30 variants with tailored properties might have lower production volumes, leading to potential challenges in sourcing them readily.

- Potential for hydrogen embrittlement: Under specific conditions, hydrogen absorption can occur, leading to a decrease in ductility and increased risk of cracking. Careful selection of manufacturing processes and post-processing techniques can mitigate this risk.

Making an Informed Decision:

Understanding both the strengths and weaknesses of HK30 empowers you to make informed decisions. Here are some key takeaways:

- HK30 excels in applications demanding high-temperature resistance, corrosion resistance, and good mechanical strength.

- Its superior powder characteristics and lower sintering temperature make it an attractive choice for complex geometries and energy-efficient manufacturing.

- The potential biocompatibility of specific grades opens doors for exciting medical device applications.

- The higher cost compared to some steels and potential limitations in sourcing custom variants necessitate careful consideration during project planning.

- By understanding the potential for hydrogen embrittlement and implementing appropriate mitigation strategies, you can ensure the long-term performance and reliability of HK30 components.

FAQ

Q: What are the main advantages of using HK30 powder for powder metallurgy?

A: HK30 offers a compelling combination of benefits: exceptional high-temperature resistance, outstanding corrosion resistance, good mechanical strength, good ductility and formability, and improved sintering behavior. These translate to superior performance, increased energy efficiency during manufacturing, and the ability to create complex geometries with consistent properties.

Q: What are some typical applications of HK30 components made using powder metallurgy?

A: HK30 finds extensive use in various industries, including automotive (turbocharger housings, exhaust manifolds), energy (gas turbine components, heat exchangers), chemical processing (reactor vessels, piping systems), and aerospace (afterburner components, exhaust ducting). Additionally, advancements in 3D printing and the potential biocompatibility of specific grades open doors for exciting new applications.

Q: How does the cost of HK30 powder compare to other materials used in powder metallurgy?

A: HK30 generally has a higher cost compared to some common steels used in powder metallurgy. However, the superior performance and potential for energy savings during manufacturing can offset the initial cost premium in many applications.

Q: Are there any limitations to consider when using HK30 powder?

A: While a powerful material, HK30 does have some limitations. These include a higher cost compared to some traditional steels, potential limitations in sourcing highly customized variants, and the need to manage the risk of hydrogen embrittlement under specific conditions. Careful planning and selection of manufacturing processes can mitigate these limitations.

Q: Where can I find more information about HK30 metal powders and suppliers?

A reputable powder metallurgy supplier can provide detailed information on specific HK30 powder offerings, pricing, and technical specifications. Additionally, several manufacturers of HK30 powder have websites with technical datasheets and information on their products.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731