Which 3D printed nickel-based alloy powder can be used in aerospace

Table of Contents

Imagine a bird soaring effortlessly through the sky. Now, picture a jet engine, the beating heart of a modern aircraft, propelling it across continents at phenomenal speeds. Both marvels of engineering share a crucial need: lightweight, incredibly strong materials that can withstand extreme temperatures and harsh environments. Enter the fascinating world of 3D printed nickel-based alloy powders, playing a starring role in the aerospace industry’s relentless pursuit of innovation.

Nickel-based alloys are a class of metallic superstars. They boast exceptional high-temperature strength, corrosion resistance, and excellent creep resistance – the ability to resist deformation under constant stress at elevated temperatures. These properties make them ideal for the brutal operating conditions endured by jet engine components. But what makes 3D printing these alloys truly revolutionary?

Let’s delve deeper into the world of 3D printed nickel-based alloy powders, exploring the specific types used in aerospace applications, their unique properties, and the advantages they offer over traditional manufacturing methods.

Common Nickel-Based Alloy Powders for Aerospace

The world of 3D printed nickel-based alloy powders is not a one-size-fits-all affair. Different alloys offer distinct advantages depending on the specific application. Here, we’ll shine a spotlight on three of the most prominent contenders:

- Inconel 718: This powerhouse alloy is the undisputed champion for many aerospace applications. Its exceptional strength-to-weight ratio, excellent high-temperature performance (up to 700°C), and good weldability make it a versatile choice for a wide range of components. Think of it as the “Swiss Army Knife” of nickel-based alloy powders, perfect for everything from turbine disks and blades to landing gear components.

- Inconel 625: Offering superior corrosion resistance compared to Inconel 718, this alloy is a lifesaver in environments prone to harsh chemicals and oxidation. Think scorching hot exhaust systems and parts exposed to saltwater for long durations. While not quite as strong as Inconel 718 at high temperatures, Inconel 625 shines in applications where battling corrosion is paramount.

- Hastelloy X: Imagine a material that thrives in environments so hostile, even other superalloys flinch. Hastelloy X steps into the ring. This champion boasts phenomenal resistance to a wide range of corrosive media, including hot hydrochloric and sulfuric acids. Think of it as the ultimate “corrosion warrior,” perfect for fuel systems, heat exchangers, and other components exposed to aggressive chemicals.

Table 1: Key Properties Comparison of Common Nickel-Based Alloy Powders

| Property | Inconel 718 | Inconel 625 | Hastelloy X |

|---|---|---|---|

| High-Temperature Strength | Excellent (up to 700°C) | Good (up to 675°C) | Moderate |

| Corrosion Resistance | Good | Excellent | Exceptional |

| Weldability | Good | Good | Fair |

| Typical Applications | Turbine disks and blades, Landing gear components | Exhaust systems, Saltwater-exposed components | Fuel systems, Heat exchangers |

Applications of Nickel-Based Alloy Powders in Aerospace

The ability to create complex, lightweight, and incredibly strong components using 3D printed nickel-based alloy powders is revolutionizing the way aircraft are designed and manufactured. Let’s explore some of the most exciting applications:

- Turbine Disks and Blades: These workhorses are the heart of a jet engine, spinning at dizzying speeds and enduring extreme temperatures. 3D printed Inconel 718 offers the perfect blend of strength and high-temperature performance for these critical components, allowing for lighter designs that improve fuel efficiency.

- Aftermarket Parts and Repair: Imagine replacing a damaged turbine blade quickly and efficiently. 3D printing with nickel-based alloy powders makes this a reality. Components can be custom-printed on-demand, minimizing downtime and maintenance costs for airlines.

- Heat Exchangers: These vital components transfer heat throughout the engine. Hastelloy X’s exceptional corrosion resistance makes it ideal for this application, ensuring the exchanger functions flawlessly in harsh environments.

- Next-Generation Engine Designs: The freedom of design offered by 3D printing allows engineers to create intricate internal cooling channels within engine components. This not only improves efficiency but also allows for the exploration of entirely new engine architectures, pushing the boundaries of performance.

Advantages of 3D Printed Nickel-Based Alloy Powders

3D printing with nickel-based alloy powders offers a distinct set of advantages compared to traditional manufacturing techniques like casting and forging:

- Design Freedom: Gone are the limitations of traditional methods like casting and forging. 3D printing allows for the creation of complex geometries with intricate internal features, previously impossible to achieve. This opens doors for lighter, more efficient engine designs that optimize airflow and heat transfer. Imagine a turbine blade with internal cooling channels that snake through its core, maximizing heat dissipation without adding bulk.

- Reduced Lead Times: Traditional manufacturing processes can be time-consuming, with long lead times for complex components. 3D printing offers a dramatic reduction in lead times. Components can be printed on-demand, significantly accelerating the design, prototyping, and production cycles. This agility is crucial in the fast-paced aerospace industry, allowing for quicker response times to new market demands and technological advancements.

- Material Efficiency: Traditional manufacturing techniques often involve significant material waste during machining and shaping processes. 3D printing utilizes a laser to selectively melt powder only where needed, minimizing waste and making it a more sustainable manufacturing option. In an industry striving to reduce its environmental footprint, this advantage is becoming increasingly important.

- Improved Buy-to-Fly Ratio: The “buy-to-fly ratio” refers to the amount of raw material needed to produce a finished flight-ready component. Traditional manufacturing can result in a high buy-to-fly ratio due to material waste. 3D printing’s inherent efficiency significantly reduces this ratio, leading to lighter aircraft with improved fuel efficiency – a critical factor in an industry obsessed with reducing operating costs and environmental impact.

Challenges and Considerations

While 3D printed nickel-based alloy powders offer tremendous potential, there are challenges to consider:

- Cost: Currently, the cost of 3D printing nickel-based alloy powders remains higher compared to traditional manufacturing techniques for certain applications. However, as technology advances and adoption rates increase, these costs are expected to come down.

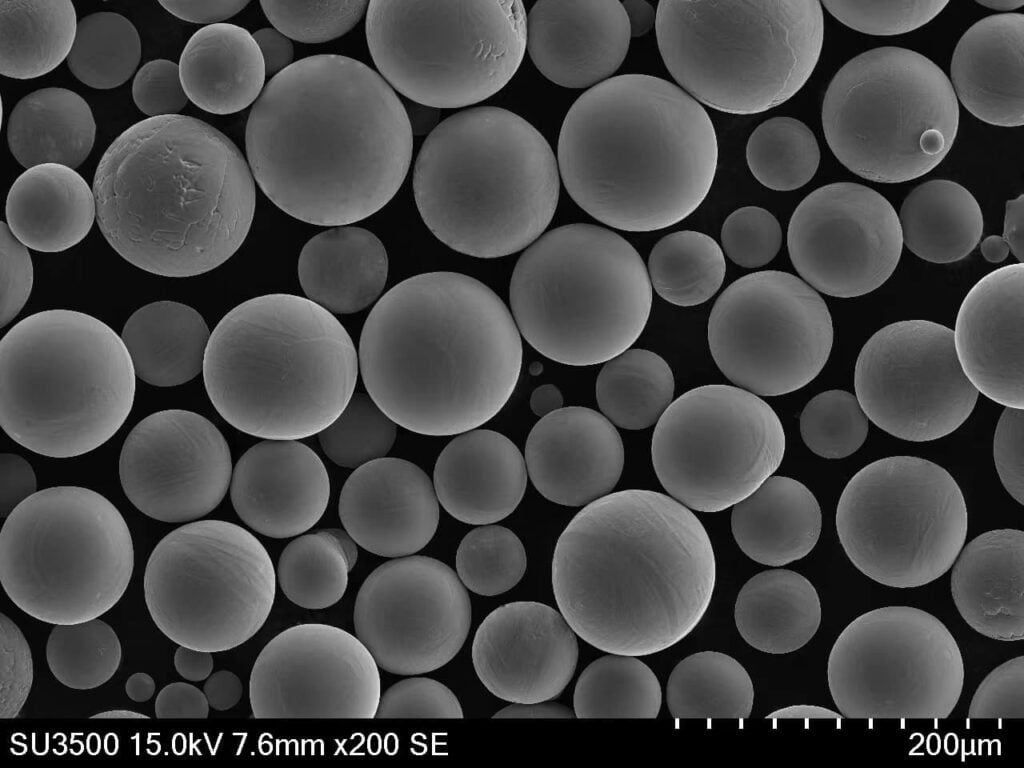

- Powder Quality: The quality and consistency of the powder play a crucial role in the final properties of the printed component. Strict quality control measures are essential to ensure parts meet the rigorous demands of aerospace applications.

- Post-Processing: 3D printed components may require additional post-processing steps like heat treatment or machining to achieve the desired final properties. Optimizing these post-processing steps is crucial for ensuring component performance and efficiency.

FAQ

Here are some of the most common questions regarding 3D printed nickel-based alloy powders in the aerospace industry:

Q: What are the benefits of using 3D printed nickel-based alloy powders compared to traditional manufacturing methods?

A: 3D printing offers advantages like design freedom, reduced lead times, improved material efficiency, and a better buy-to-fly ratio.

Q: Which nickel-based alloy powders are most commonly used in aerospace applications?

A: Inconel 718, Inconel 625, and Hastelloy X are some of the most popular choices due to their unique properties like high-temperature strength, corrosion resistance, and weldability.

Q: What are the challenges associated with using 3D printed nickel-based alloy powders?

A: Cost, powder quality, and the need for post-processing are some of the key challenges that are being addressed through ongoing advancements in technology and manufacturing processes.

Q: What is the future of 3D printed nickel-based alloy powders in the aerospace industry?

A: The future looks bright. As technology advances, costs decrease, and powder quality improves, 3D printing is poised to play an increasingly significant role in the design and production of next-generation aircraft, pushing the boundaries of performance and efficiency.

Conclusion

The marriage of 3D printing technology and nickel-based alloy powders is a game-changer for the aerospace industry. It unlocks new possibilities for design innovation, lighter, more efficient aircraft, and faster production cycles. While challenges remain, the potential benefits are undeniable. As we look to the future skies, 3D printed nickel-based alloy powders are sure to play a vital role in propelling us towards a new era of aerospace exploration and achievement.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731