Nickel Oxide Nanopowder

Table of Contents

Nickel oxide nanopowder is a unique and highly sought-after material that has been gaining significant attention in various industries due to its exceptional properties and wide-ranging applications. In this comprehensive article, we will delve into the fascinating world of nickel oxide nanopowder, exploring its composition, characteristics, applications, and the latest advancements in this field.

Overview of Nickel Oxide Nanopowder

Nickel oxide nanopowder is a nanostructured form of nickel oxide (NiO), a compound composed of nickel and oxygen atoms. At the nanoscale, these particles exhibit unique properties that differ from their bulk counterparts, making them highly desirable for a variety of applications. Nanopowders are characterized by their incredibly small particle size, typically ranging from 1 to 100 nanometers (nm) in at least one dimension.

One of the key advantages of nickel oxide nanopowder is its high surface area-to-volume ratio, which results in increased reactivity and improved performance in catalytic processes, energy storage systems, and sensor applications. Additionally, the unique properties of nanomaterials often lead to enhanced mechanical strength, thermal stability, and optical properties compared to conventional materials.

Composition and Properties of Nickel Oxide Nanopowder

| Property | Description |

|---|---|

| Chemical Formula | NiO |

| Color | Green |

| Crystal Structure | Face-centered cubic (fcc) or rock salt structure |

| Particle Size | Typically 1 to 100 nm |

| Surface Area | High surface area, often exceeding 100 m²/g |

| Electrical Conductivity | Semiconductor |

| Magnetic Properties | Antiferromagnetic |

| Thermal Stability | Stable up to high temperatures |

Nickel oxide nanopowder exhibits a distinct green color due to its unique electronic structure. It crystallizes in a face-centered cubic (fcc) or rock salt structure, where nickel and oxygen atoms are arranged in a cubic pattern. The small particle size and high surface area contribute to the enhanced reactivity and performance of nickel oxide nanopowder in various applications.

Industrial Applications of Nickel Oxide Nanopowder

| Application | Description |

|---|---|

| Catalysis | Used as a catalyst or catalyst support in various chemical reactions, such as reforming, oxidation, and hydrogenation processes. |

| Energy Storage | Employed as an electrode material in lithium-ion batteries, supercapacitors, and fuel cells due to its high surface area and electrochemical properties. |

| Sensors | Utilized in gas sensors, biosensors, and chemical sensors due to its sensitivity and ability to detect various gases and biomolecules. |

| Electronics | Incorporated into electronic devices, such as resistive random-access memory (RRAM), transistors, and optoelectronic devices, due to its unique electrical and optical properties. |

| Ceramics | Used as an additive in ceramic materials to improve mechanical strength, thermal stability, and other properties. |

| Coatings | Applied as a protective coating on various surfaces to enhance corrosion resistance, wear resistance, and thermal insulation. |

Nickel oxide nanopowder finds applications across numerous industries due to its exceptional properties. It serves as a catalyst or catalyst support in various chemical reactions, such as reforming, oxidation, and hydrogenation processes, enabling more efficient and selective reactions. Additionally, its high surface area and electrochemical properties make it an attractive material for energy storage applications, including lithium-ion batteries, supercapacitors, and fuel cells.

In the field of sensors, nickel oxide nanopowder is employed in gas sensors, biosensors, and chemical sensors due to its sensitivity and ability to detect various gases and biomolecules. Furthermore, its unique electrical and optical properties make it suitable for use in electronic devices, such as resistive random-access memory (RRAM), transistors, and optoelectronic devices.

Nickel oxide nanopowder is also utilized as an additive in ceramic materials to improve mechanical strength, thermal stability, and other properties. Additionally, it can be applied as a protective coating on various surfaces to enhance corrosion resistance, wear resistance, and thermal insulation.

Specifications and Grades of Nickel Oxide Nanopowder

| Specification | Description |

|---|---|

| Purity | Typically available in purities ranging from 99% to 99.9% |

| Particle Size | Offered in various particle sizes, such as <50 nm, <100 nm, and <200 nm |

| Surface Area | Surface areas ranging from 10 m²/g to over 100 m²/g |

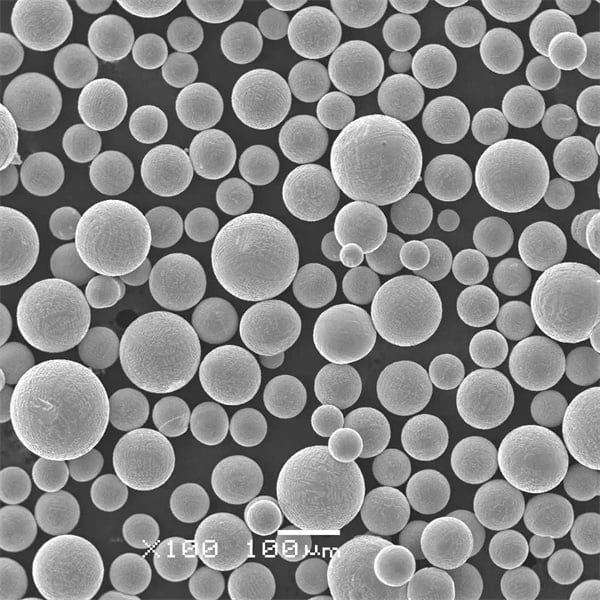

| Morphology | Spherical, cubic, or irregular shapes |

| Density | Bulk density ranging from 0.5 to 1.5 g/cm³ |

| Surface Modification | Available with various surface modifications for improved dispersion and compatibility |

Nickel oxide nanopowder is available in different specifications and grades to meet the diverse requirements of various applications. Purity levels ranging from 99% to 99.9% are common, ensuring high-quality and consistent performance. Particle sizes are offered in different ranges, such as <50 nm, <100 nm, and <200 nm, to cater to specific application needs.

Surface area is a crucial parameter, with nickel oxide nanopowders typically available with surface areas ranging from 10 m²/g to over 100 m²/g. The morphology of the particles can vary, including spherical, cubic, or irregular shapes, depending on the synthesis method and desired properties.

Bulk density, an important factor for handling and processing, ranges from 0.5 to 1.5 g/cm³ for nickel oxide nanopowders. Additionally, surface modifications are available to improve dispersion and compatibility with various matrices or composite materials.

Suppliers and Pricing of Nickel Oxide Nanopowder

| Supplier | Price Range (USD/kg) |

|---|---|

| Sigma-Aldrich | $200 – $500 |

| Strem Chemicals | $150 – $400 |

| American Elements | $100 – $350 |

| Nanoamor | $150 – $450 |

| US Research Nanomaterials | $120 – $300 |

Nickel oxide nanopowder is widely available from various suppliers, both commercial and research-grade. The pricing can vary significantly depending on factors such as purity, particle size, surface area, and quantities ordered. Generally, smaller quantities are more expensive on a per-kilogram basis.

Sigma-Aldrich, a leading supplier of chemicals and materials, offers nickel oxide nanopowder at prices ranging from $200 to $500 per kilogram, depending on the specifications. Strem Chemicals, specializing in high-purity materials, provides nickel oxide nanopowder at prices between $150 and $400 per kilogram.

American Elements, a renowned supplier of advanced materials, offers nickel oxide nanopowder at competitive prices ranging from $100 to $350 per kilogram. Nanoamor, a company focused on nanomaterials, offers nickel oxide nanopowder at prices between $150 and $450 per kilogram, catering to various application requirements.

US Research Nanomaterials, a specialized supplier of nanomaterials, provides nickel oxide nanopowder at prices ranging from $120 to $300 per kilogram, offering a cost-effective option for researchers and industry professionals.

It is important to note that these prices are subject to change and may vary based on market conditions, demand, and other factors. Additionally, bulk discounts and custom orders may be available from some suppliers, enabling more cost-effective procurement for larger-scale applications.

Pros and Cons of Nickel Oxide Nanopowder

| Pros | Cons |

|---|---|

| High surface area-to-volume ratio | Potential health and environmental concerns |

| Enhanced reactivity and catalytic activity | Costly production and processing |

| Improved electrochemical properties | Agglomeration and dispersion challenges |

| Unique optical and electronic properties | Limited long-term stability in some applications |

| Tunable properties through surface modifications | Potential safety hazards during handling |

| Wide range of applications | Need for specialized equipment and facilities |

Like any material, nickel oxide nanopowder has its advantages and disadvantages. One of the major pros is its high surface area-to-volume ratio, which results in enhanced reactivity and catalytic activity. This property makes it attractive for applications in catalysis, energy storage, and sensing.

Additionally, nickel oxide nanopowder exhibits improved electrochemical properties, making it suitable for use in batteries, supercapacitors, and fuel cells. Its unique optical and electronic properties also open up opportunities in electronics and optoelectronics.

Another advantage of nickel oxide nanopowder is the ability to tune its properties through surface modifications, allowing for customization to specific applications. Furthermore, its wide range of applications across various industries adds to its versatility and value.

However, there are also some cons associated with nickel oxide nanopowder. Potential health and environmental concerns arise due to the small size of nanoparticles, which can pose risks if not handled and disposed of properly. The production and processing of nanomaterials can be costly, especially for large-scale applications.

Agglomeration and dispersion challenges are common issues with nanopowders, which can affect their performance and require specialized techniques to address. Additionally, the long-term stability of nickel oxide nanopowder may be limited in certain applications, necessitating careful consideration and testing.

Potential safety hazards during handling and the need for specialized equipment and facilities are other factors that must be taken into account when working with nickel oxide nanopowder. Proper safety protocols and appropriate containment measures are crucial to mitigate risks.

FAQs

| Question | Answer |

|---|---|

| Q: What makes nickel oxide nanopowder unique? | A: Nickel oxide nanopowder exhibits unique properties due to its small particle size and high surface area-to-volume ratio, which lead to enhanced reactivity, catalytic activity, and improved electrochemical properties. |

| Q: How is nickel oxide nanopowder produced? | A: Nickel oxide nanopowder can be produced through various synthesis methods, including chemical vapor deposition, sol-gel processes, hydrothermal synthesis, and precipitation techniques. The choice of method depends on the desired characteristics, such as particle size, morphology, and purity. |

| Q: What are the safety concerns associated with nickel oxide nanopowder? | A: Like many nanomaterials, nickel oxide nanopowder may pose potential health and environmental risks due to its small size and increased reactivity. Proper handling, containment, and disposal procedures must be followed to mitigate these risks. |

| Q: Can nickel oxide nanopowder be used in batteries? | A: Yes, nickel oxide nanopowder is widely used as an electrode material in lithium-ion batteries and other energy storage devices due to its high surface area and favorable electrochemical properties. |

| Q: How does the particle size of nickel oxide nanopowder affect its performance? | A: The particle size of nickel oxide nanopowder has a significant impact on its performance. Smaller particle sizes generally lead to increased surface area and reactivity, but may also present challenges in terms of agglomeration and dispersion. |

| Q: Are there any limitations to the applications of nickel oxide nanopowder? | A: While nickel oxide nanopowder has a wide range of applications, its long-term stability and performance may be limited in certain environments or conditions. Additionally, the cost and specialized equipment required for production and processing can be limiting factors for some applications. |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731