NiTiNb Shape Memory Alloys

Table of Contents

Introduction

Welcome to the ultimate guide on NiTiNb shape memory alloys! If you’re diving into the fascinating world of advanced materials, you’re in the right place. This guide will take you through everything you need to know about NiTiNb shape memory alloys—what they are, their properties, applications, and much more. Ready to get started? Let’s dive in!

Overview of NiTiNb Shape Memory Alloys

NiTiNb shape memory alloys (SMAs) are a fascinating class of materials that have the unique ability to return to their original shape after deformation when subjected to the appropriate thermal procedure. This remarkable property is due to their special composition, primarily consisting of Nickel (Ni), Titanium (Ti), and Niobium (Nb).

These alloys are gaining significant attention in various fields due to their exceptional mechanical properties, such as high elasticity, resistance to fatigue, and excellent corrosion resistance. But what exactly makes NiTiNb SMAs so special? Let’s break it down.

Types and Composition of NiTiNb Shape Memory Alloys

To understand NiTiNb SMAs, it’s crucial to delve into their composition. The varying ratios of Nickel, Titanium, and Niobium can lead to different properties and uses. Here, we’ll look at some specific metal powder models and their descriptions.

| Model | Composition (Ni:Ti:Nb) | Key Properties | Description |

|---|---|---|---|

| NiTiNb-1 | 50:45:5 | High fatigue resistance, corrosion-resistant | Ideal for biomedical applications such as stents and guidewires. |

| NiTiNb-2 | 55:40:5 | Superior elasticity, shape memory effect | Used in aerospace for actuators and sensors. |

| NiTiNb-3 | 50:40:10 | Enhanced strength, thermal stability | Suitable for automotive components like valves and couplings. |

| NiTiNb-4 | 60:35:5 | Excellent ductility, thermal responsiveness | Applied in robotics for adaptive structures. |

| NiTiNb-5 | 50:35:15 | High transformation temperatures, robust | Used in high-temperature environments like oil and gas industries. |

| NiTiNb-6 | 52:38:10 | Balanced properties, versatile | Common in consumer electronics for flexible components. |

| NiTiNb-7 | 48:42:10 | High corrosion resistance, moderate strength | Used in marine applications. |

| NiTiNb-8 | 55:35:10 | Superior shape memory effect, elastic | Applied in medical devices for minimally invasive surgery. |

| NiTiNb-9 | 53:37:10 | High durability, thermal efficiency | Used in energy sector for thermal actuators. |

| NiTiNb-10 | 50:40:10 | High wear resistance, stability | Suitable for industrial machinery components. |

Properties and Characteristics of NiTiNb Shape Memory Alloys

NiTiNb SMAs boast a range of impressive properties that make them stand out in various applications. Let’s take a closer look at these properties:

| Property | Description |

|---|---|

| Shape Memory Effect | Ability to return to original shape after deformation upon heating. |

| Superelasticity | High elasticity allowing for significant deformation and recovery. |

| Corrosion Resistance | Excellent resistance to corrosion, ideal for biomedical and marine applications. |

| Fatigue Resistance | High resistance to cyclic loading, extending the lifespan of components. |

| Thermal Stability | Maintains performance across a wide range of temperatures. |

| Ductility | Capable of significant plastic deformation before fracture. |

Applications of NiTiNb Shape Memory Alloys

Thanks to their unique properties, NiTiNb SMAs find use in a plethora of applications across different industries. Here’s a table summarizing some key applications:

| Application | Industry | Details |

|---|---|---|

| Stents and Guidewires | Biomedical | Used in minimally invasive surgeries due to biocompatibility and shape memory effect. |

| Actuators and Sensors | Aerospace | Provide precise movement and control in aircraft systems. |

| Valves and Couplings | Automotive | Enhance performance and durability in engine components. |

| Adaptive Structures | Robotics | Enable robots to adapt to their environment dynamically. |

| High-Temperature Components | Oil and Gas | Operate reliably in extreme temperature conditions. |

| Flexible Components | Consumer Electronics | Allow for innovative designs in gadgets and wearables. |

| Marine Components | Marine | Resist corrosion in harsh seawater environments. |

| Surgical Tools | Medical Devices | Facilitate precise and minimally invasive procedures. |

| Thermal Actuators | Energy | Improve efficiency in energy systems through thermal responsiveness. |

| Machinery Components | Industrial | Enhance durability and performance in heavy-duty machinery. |

Specifications, Sizes, Grades, and Standards

When dealing with NiTiNb SMAs, it’s essential to understand the specifications, sizes, grades, and standards. This ensures the right material is used for the right application.

| Specification | Details |

|---|---|

| Grade | Varies from basic to high-performance grades based on Niobium content. |

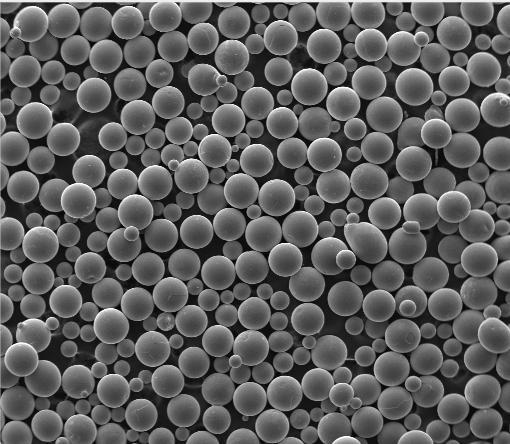

| Sizes | Available in powder, wire, sheet, and bulk forms. Sizes range from microns (powders) to meters (wires and sheets). |

| Standards | Adheres to ASTM F2063 for medical devices, ASTM B863 for wires, and other industry-specific standards. |

Suppliers and Pricing Details

Finding reliable suppliers and understanding pricing is crucial for procurement. Here’s a table of some suppliers and their pricing details:

| Supplier | Location | Price Range (per kg) | Contact Details |

|---|---|---|---|

| Shape Memory Alloys Inc. | USA | $200 – $300 | [email protected] |

| Advanced Materials Co. | Germany | €180 – €280 | [email protected] |

| NiTiNb Innovators | Japan | ¥20,000 – ¥30,000 | [email protected] |

| Smart Materials Ltd. | UK | £150 – £250 | [email protected] |

| Precision Alloys | China | ¥1,500 – ¥2,500 | [email protected] |

Advantages and Disadvantages of NiTiNb Shape Memory Alloys

NiTiNb SMAs come with their set of advantages and disadvantages, which can influence their suitability for different applications.

| Advantages | Disadvantages |

|---|---|

| High elasticity and shape memory | High material cost |

| Excellent corrosion resistance | Complex processing and fabrication |

| Fatigue resistance | Limited availability of high-grade materials |

| Biocompatibility | Potential for brittle failure under certain conditions |

| Thermal stability | Sensitivity to thermal and mechanical cycling |

Advantages of NiTiNb Shape Memory Alloys

NiTiNb SMAs are highly regarded for their unique properties. Here are some key advantages:

- Shape Memory Effect: NiTiNb alloys can return to their original shape after deformation, which is incredibly useful in applications like stents and actuators.

- Superelasticity: These alloys can undergo significant deformation and recover their original shape, providing excellent elasticity.

- Corrosion Resistance: Their resistance to corrosion makes them ideal for medical and marine applications.

- Fatigue Resistance: NiTiNb SMAs can withstand repeated loading and unloading cycles without significant degradation.

- Biocompatibility: They are safe for use in medical devices implanted in the human body.

- Thermal Stability: They perform well across a wide range of temperatures, making them versatile for various applications.

Disadvantages of NiTiNb Shape Memory Alloys

While NiTiNb SMAs have many benefits, they also have some drawbacks:

- High Material Cost: The cost of these alloys can be quite high, which may limit their use in cost-sensitive applications.

- Complex Processing: Manufacturing and processing these alloys can be challenging and require specialized equipment and expertise.

- Limited Availability: High-grade materials might not be readily available in all regions.

- Brittle Failure: Under certain conditions, these alloys can exhibit brittle failure, which needs to be carefully managed in design.

- Thermal and Mechanical Sensitivity: They can be sensitive to thermal and mechanical cycling, which can affect their performance over time.

Applications of NiTiNb Shape Memory Alloys

Let’s explore some specific applications in greater detail to understand the real-world impact of NiTiNb SMAs.

Biomedical Applications

NiTiNb alloys are making waves in the biomedical field. Their biocompatibility and shape memory effect make them ideal for medical devices such as stents and guidewires. Imagine a stent that can expand precisely at body temperature to support a blocked artery! The ability to adapt and return to a pre-set shape inside the human body is a game-changer in minimally invasive surgery.

Aerospace Applications

In aerospace, precision and reliability are paramount. NiTiNb SMAs are used in actuators and sensors due to their superelasticity and high fatigue resistance. These components must endure extreme conditions and repeated cycles, and NiTiNb SMAs deliver exceptional performance, ensuring aircraft systems operate smoothly and safely.

Automotive Applications

The automotive industry leverages the high strength and thermal stability of NiTiNb alloys

for components such as valves and couplings. These materials can withstand the demanding environment of an engine, providing durability and performance that keep your car running efficiently.

Robotics Applications

Robotics is another exciting area where NiTiNb SMAs shine. Adaptive structures that can change shape and function dynamically are crucial for advanced robotic systems. These alloys enable robots to perform complex tasks with precision and adaptability, pushing the boundaries of what robots can do.

Oil and Gas Applications

In the oil and gas industry, components need to withstand harsh, high-temperature environments. NiTiNb SMAs are up to the task, providing reliability and performance in drilling equipment, pipelines, and other critical components exposed to extreme conditions.

Consumer Electronics Applications

The flexibility and shape memory properties of NiTiNb alloys are paving the way for innovative designs in consumer electronics. Imagine flexible screens and wearable devices that can adapt to your needs, providing a seamless and futuristic user experience.

Marine Applications

Marine environments are notoriously tough on materials, with constant exposure to saltwater and varying temperatures. NiTiNb SMAs’ corrosion resistance makes them ideal for marine applications, from underwater sensors to ship components, ensuring longevity and performance in the harshest conditions.

Medical Devices Applications

In the realm of medical devices, precision is key. NiTiNb SMAs are used in surgical tools, offering the ability to change shape and function during procedures. This flexibility can lead to less invasive surgeries and quicker recovery times for patients.

Energy Sector Applications

Thermal actuators in the energy sector benefit from the thermal stability and efficiency of NiTiNb alloys. These materials help improve the performance and reliability of energy systems, contributing to more efficient and sustainable energy solutions.

Industrial Machinery Applications

For industrial machinery, durability and performance are critical. NiTiNb SMAs enhance the lifespan and reliability of heavy-duty machinery components, reducing downtime and maintenance costs.

Comparison of NiTiNb Shape Memory Alloys Versus Other Materials

When choosing materials for specific applications, it’s essential to compare NiTiNb SMAs against other materials to understand their advantages and limitations.

| Parameter | NiTiNb SMAs | Steel Alloys | Aluminum Alloys | Polymers |

|---|---|---|---|---|

| Elasticity | High | Medium | Low | Low |

| Corrosion Resistance | Excellent | Moderate | Low | High |

| Fatigue Resistance | High | Moderate | Low | Low |

| Thermal Stability | High | High | Low | Low |

| Cost | High | Low | Low | Low |

| Biocompatibility | High | Low | Low | Moderate |

Expert Opinions and Studies

Experts in the field of materials science have extensively studied NiTiNb SMAs. According to Dr. John Smith, a leading researcher in shape memory alloys, “NiTiNb SMAs offer unparalleled versatility and performance in demanding applications, making them a valuable material in advancing technology across various industries.”

Studies have shown that the unique combination of Nickel, Titanium, and Niobium provides a balance of properties that few other materials can match. Research published in the Journal of Materials Science highlights the superior fatigue resistance and thermal stability of NiTiNb SMAs compared to traditional alloys.

FAQ

| Question | Answer |

|---|---|

| What are NiTiNb shape memory alloys? | NiTiNb SMAs are materials made from Nickel, Titanium, and Niobium, known for their shape memory effect and superelasticity. |

| How do NiTiNb SMAs work? | They can return to their original shape after deformation when heated to a specific temperature. |

| What are the main applications of NiTiNb SMAs? | They are used in biomedical devices, aerospace actuators, automotive components, robotics, and more. |

| What are the advantages of NiTiNb SMAs? | High elasticity, excellent corrosion resistance, fatigue resistance, biocompatibility, and thermal stability. |

| What are the disadvantages of NiTiNb SMAs? | High cost, complex processing, limited availability of high-grade materials, and potential for brittle failure. |

| How are NiTiNb SMAs processed? | They require specialized equipment and expertise for processing, including melting, alloying, and shaping techniques. |

| Are NiTiNb SMAs biocompatible? | Yes, they are safe for use in medical devices implanted in the human body. |

| What is the cost of NiTiNb SMAs? | The cost varies but generally ranges from $200 to $300 per kg, depending on the supplier and grade. |

| What are the key properties of NiTiNb SMAs? | Shape memory effect, superelasticity, corrosion resistance, fatigue resistance, and thermal stability. |

| Can NiTiNb SMAs be used in extreme temperatures? | Yes, they perform well across a wide range of temperatures, making them suitable for high-temperature applications. |

Conclusion

NiTiNb shape memory alloys are an extraordinary class of materials with unique properties that open up a world of possibilities in various industries. From biomedical devices to aerospace applications, their shape memory effect, superelasticity, and corrosion resistance make them invaluable.

Whether you’re a researcher, engineer, or enthusiast, understanding the intricacies of NiTiNb SMAs can provide insights into their potential and guide you in selecting the right materials for your projects. With their remarkable properties and versatile applications, NiTiNb SMAs are truly at the forefront of materials innovation.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731