Product

Product Category

Best inconel 718 powder for 3D printing

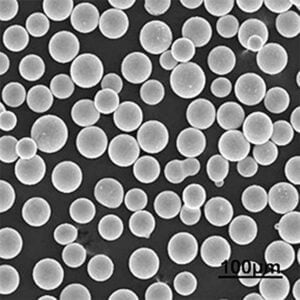

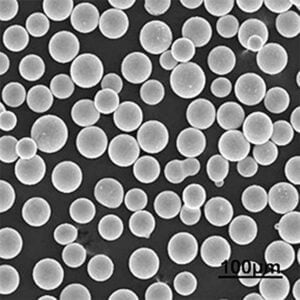

Inconel 718 powder (IN718) is a well-known nickel-based superalloy powder that is extensively used in high-value-added engineering applications such as jet engines in aerospace and steam generators in nuclear power plants, as well as in the defense and marine sectors.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

Best Stainless Steel 316L Powder for 3D Printing

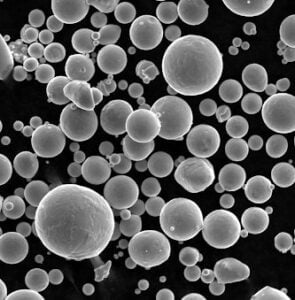

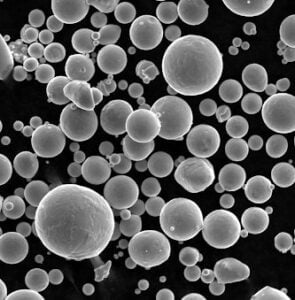

Stainless steel 316L powder is a versatile and widely used material in various industries. Its unique properties make it suitable for applications ranging from 3D printing to biomedical implants. In this article, we will explore the characteristics, uses, manufacturing process, and advantages of stainless steel 316L powder.

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

TC4 powder, also known as Ti-6Al-4V, is a titanium alloy powder composed of 90% titanium (Ti), 6% aluminum (Al), and 4% vanadium (V). It is widely recognized for its exceptional strength, low density, and excellent corrosion resistance. TC4 powder is extensively utilized across industries due to its unique combination of properties, making it a highly sought-after material for various applications.

Chromium CoCr Powder

Chromium CoCr powder, also known as cobalt-chromium powder, is a specialized metal powder used in various industrial applications such as metal 3D printing, surface coating, and the manufacturing of medical implants.

It is an alloy composed primarily of cobalt and chromium, with additional elements like molybdenum, nickel, iron, manganese, and silicon added in smaller quantities. The exact composition can be customized as per application requirements.

Chromium CoCr alloys are valued for properties like high strength, corrosion resistance, biocompatibility, and wear resistance. The powder metallurgy process allows components with complex geometries to be manufactured from this material.

Cobalt Chrome CoCrMo Powder

Cobalt Chrome CoCrMo Powder, specifically CoCrMo, is a cobalt-based alloy powder used in various metal powder applications such as metal injection molding (MIM) and additive manufacturing (AM).

Some key details about cobalt chrome CoCrMo alloy powder:

- Composition – Made up primarily of cobalt along with chromium, molybdenum, and small amounts of other elements like tungsten, nickel, iron, silicon, manganese, and carbon

Cobalt Chrome F75 Powder

Cobalt chrome F75 powder refers specifically to a cobalt-chromium alloy powder meeting ASTM F75 standards for composition and particle size distribution. It is a versatile cobalt-based alloy powder used in various metal 3D printing processes to create end-use orthopedic implants and dental restorations.

Some key details about cobalt chrome F75 powder include:

Composition

- Predominantly cobalt and chromium, along with molybdenum and smaller amounts of other alloying elements

CoCr28Mo6 Powder

CoCr28Mo6 powder, also known as ASTM F75 alloy, is a cobalt-chromium-molybdenum alloy powder used for manufacturing of orthopedic implants due to its biocompatibility, high strength and corrosion resistance.

CoCrFeNi Powder

CoCrFeNi powder, also known as CoCrFeNiMn powder or high entropy alloy (HEA) powder, refers to a material composed of cobalt, chromium, iron, and nickel elements in near-equiatomic ratios. This novel alloy powder displays exceptional properties compared to conventional alloys and has garnered significant interest for various applications.

CoCrMo Powder

CoCrMo is a cobalt-chromium-molybdenum alloy powder widely used in metal additive manufacturing for biomedical, dental, aerospace, and industrial applications needing wear resistance and biocompatibility.

CoCrMoW Powder

CoCrMoW powder is a cobalt-chromium-molybdenum-tungsten alloy powder used primarily for manufacturing of orthopedic joint implants. The addition of tungsten further enhances the strength, wear resistance and hardness compared to CoCrMo alloys.

CoCrW Powder for metal 3D printing

CoCrW is one of the the stellite alloys, which can resist various types of wear, corrosion and oxidation at high temperature. According to the compositions of alloys, they can be made into welding wire, powder to be used for hard surface surfacing, thermal spraying, spray welding. They can also be made into castings, forgings and powder metallurgy parts.

Copper alloy series

Copper alloy series powders use copper as the main component and incorporate a variety of alloy elements to provide excellent conductivity and corrosion resistance for various application fields. Let’s explore this range of products together and discover their wide range of applications in different industries.

Copper C11000 Powder

Copper C11000 powder, also known as electrolytic tough pitch (ETP) copper powder, is a high purity copper powder produced through electrolytic processes. It has a minimum copper content of 99.9% and is known for its combination of purity, outstanding electrical and thermal conductivity, corrosion resistance, and workability.

Copper C17510 Powder

Copper C17510 powder is a copper-based alloy powder that contains nickel, silicon, and chromium as its main alloying elements. It is known for having high strength, good corrosion resistance, excellent brazeability, and high thermal and electrical conductivity.

Copper-base Solder

Copper solder paste is prepared by a special process from copper-based brazing powder, trace active components, solvents, polymer carriers and other additives.

CPTi Powder

CPTi (chemically pure titanium) powder is a high purity titanium metal powder used in various applications requiring excellent corrosion resistance, high strength, low weight, and biocompatibility. It offers superior properties compared to other titanium grades and alloy powders.

Best inconel 718 powder for 3D printing

Inconel 718 powder (IN718) is a well-known nickel-based superalloy powder that is extensively used in high-value-added engineering applications such as jet engines in aerospace and steam generators in nuclear power plants, as well as in the defense and marine sectors.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

Best Stainless Steel 316L Powder for 3D Printing

Stainless steel 316L powder is a versatile and widely used material in various industries. Its unique properties make it suitable for applications ranging from 3D printing to biomedical implants. In this article, we will explore the characteristics, uses, manufacturing process, and advantages of stainless steel 316L powder.

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

TC4 powder, also known as Ti-6Al-4V, is a titanium alloy powder composed of 90% titanium (Ti), 6% aluminum (Al), and 4% vanadium (V). It is widely recognized for its exceptional strength, low density, and excellent corrosion resistance. TC4 powder is extensively utilized across industries due to its unique combination of properties, making it a highly sought-after material for various applications.

Chromium CoCr Powder

Chromium CoCr powder, also known as cobalt-chromium powder, is a specialized metal powder used in various industrial applications such as metal 3D printing, surface coating, and the manufacturing of medical implants.

It is an alloy composed primarily of cobalt and chromium, with additional elements like molybdenum, nickel, iron, manganese, and silicon added in smaller quantities. The exact composition can be customized as per application requirements.

Chromium CoCr alloys are valued for properties like high strength, corrosion resistance, biocompatibility, and wear resistance. The powder metallurgy process allows components with complex geometries to be manufactured from this material.

Cobalt Chrome CoCrMo Powder

Cobalt Chrome CoCrMo Powder, specifically CoCrMo, is a cobalt-based alloy powder used in various metal powder applications such as metal injection molding (MIM) and additive manufacturing (AM).

Some key details about cobalt chrome CoCrMo alloy powder:

- Composition – Made up primarily of cobalt along with chromium, molybdenum, and small amounts of other elements like tungsten, nickel, iron, silicon, manganese, and carbon

Cobalt Chrome F75 Powder

Cobalt chrome F75 powder refers specifically to a cobalt-chromium alloy powder meeting ASTM F75 standards for composition and particle size distribution. It is a versatile cobalt-based alloy powder used in various metal 3D printing processes to create end-use orthopedic implants and dental restorations.

Some key details about cobalt chrome F75 powder include:

Composition

- Predominantly cobalt and chromium, along with molybdenum and smaller amounts of other alloying elements

CoCr28Mo6 Powder

CoCr28Mo6 powder, also known as ASTM F75 alloy, is a cobalt-chromium-molybdenum alloy powder used for manufacturing of orthopedic implants due to its biocompatibility, high strength and corrosion resistance.

CoCrFeNi Powder

CoCrFeNi powder, also known as CoCrFeNiMn powder or high entropy alloy (HEA) powder, refers to a material composed of cobalt, chromium, iron, and nickel elements in near-equiatomic ratios. This novel alloy powder displays exceptional properties compared to conventional alloys and has garnered significant interest for various applications.

CoCrMo Powder

CoCrMo is a cobalt-chromium-molybdenum alloy powder widely used in metal additive manufacturing for biomedical, dental, aerospace, and industrial applications needing wear resistance and biocompatibility.

CoCrMoW Powder

CoCrMoW powder is a cobalt-chromium-molybdenum-tungsten alloy powder used primarily for manufacturing of orthopedic joint implants. The addition of tungsten further enhances the strength, wear resistance and hardness compared to CoCrMo alloys.

CoCrW Powder for metal 3D printing

CoCrW is one of the the stellite alloys, which can resist various types of wear, corrosion and oxidation at high temperature. According to the compositions of alloys, they can be made into welding wire, powder to be used for hard surface surfacing, thermal spraying, spray welding. They can also be made into castings, forgings and powder metallurgy parts.

Copper alloy series

Copper alloy series powders use copper as the main component and incorporate a variety of alloy elements to provide excellent conductivity and corrosion resistance for various application fields. Let’s explore this range of products together and discover their wide range of applications in different industries.

Copper C11000 Powder

Copper C11000 powder, also known as electrolytic tough pitch (ETP) copper powder, is a high purity copper powder produced through electrolytic processes. It has a minimum copper content of 99.9% and is known for its combination of purity, outstanding electrical and thermal conductivity, corrosion resistance, and workability.

Copper C17510 Powder

Copper C17510 powder is a copper-based alloy powder that contains nickel, silicon, and chromium as its main alloying elements. It is known for having high strength, good corrosion resistance, excellent brazeability, and high thermal and electrical conductivity.

Copper-base Solder

Copper solder paste is prepared by a special process from copper-based brazing powder, trace active components, solvents, polymer carriers and other additives.

CPTi Powder

CPTi (chemically pure titanium) powder is a high purity titanium metal powder used in various applications requiring excellent corrosion resistance, high strength, low weight, and biocompatibility. It offers superior properties compared to other titanium grades and alloy powders.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731