Quick-Turnaround Metal Additive Manufacturing in Seoul

Table of Contents

1. Introduction: The Demand for Fast Metal Additive Manufacturing in Seoul

In recent years, Seoul has emerged as a major hub for smart manufacturing and high-tech industrial development. The growing demand for speed, customization, and precision in product development has fueled the rise of quick-turnaround metal additive manufacturing (AM) across the city’s industrial ecosystem.

From automotive prototyping in Gyeonggi-do to aerospace component testing in Daedeok Innopolis and medical device innovation in Gangnam, manufacturers are under pressure to move faster than ever. Traditional machining and casting processes are no longer sufficient to meet the rapid iterative cycles demanded by today’s competitive markets.

That’s where metal additive manufacturing comes in — a disruptive technology that enables fast, precise, and cost-effective production of complex metal parts, directly from digital files.

Why Quick-Turnaround Matters in South Korea

South Korea’s innovation-driven economy emphasizes speed-to-market and precision engineering. This is especially true in:

- Electronics & Semiconductor Equipment

- Electric Vehicles (EVs) & Battery Components

- Defense and Aerospace Industries

- Medical Implants and Instruments

For these sectors, access to fast, high-quality metal 3D printing can mean the difference between winning or losing a contract, launching a product on time, or achieving compliance with international standards.

Common Use-Cases in Seoul for Quick Metal AM

| Industry | Application | Lead Time Requirement |

|---|---|---|

| Aerospace | Prototyping turbine blades | ≤ 7 days |

| Automotive | Custom engine brackets | ≤ 5 days |

| Medical | Patient-specific implants | ≤ 10 days |

| Robotics | Lightweight structural parts | ≤ 6 days |

| Electronics | Heat sinks & connectors | ≤ 3–5 days |

As more Korean manufacturers embrace digital manufacturing, the need for fast-turnaround AM suppliers becomes critical. However, not all providers are equipped to deliver high-quality results at speed.

2. Market Trends: Rise of Metal 3D Printing in South Korea’s Manufacturing Sector

South Korea ranks among the top global adopters of advanced manufacturing technologies. According to the Korea Institute of Industrial Technology (KITECH), metal additive manufacturing usage in the country has grown by over 30% year-over-year since 2020.

This rise is being driven by several key trends:

✅ Key Drivers of AM Growth in South Korea

- Smart Factory Initiatives: Government programs such as “Manufacturing Innovation 3.0” push for digital transformation.

- Defense and Aerospace Investment: Defense contractors are adopting AM to produce lightweight, high-strength components.

- Healthcare Personalization: Surgeons and hospitals increasingly use metal 3D printed implants and tools.

- EV and Battery Market Boom: Korean giants like LG Energy Solution and Hyundai are investing in AM for fast prototyping.

- Supply Chain Resilience: COVID-19 exposed vulnerabilities in traditional supply chains, prompting a shift to local, just-in-time production.

Metal AM Market Size in Korea

| Year | Estimated Market Value (USD) | YoY Growth |

|---|---|---|

| 2020 | $110 million | – |

| 2021 | $145 million | +31.8% |

| 2022 | $192 million | +32.4% |

| 2023 | $250 million (est.) | +30.2% |

Industries Driving Demand in Seoul

| Industry Sector | % of Total Metal AM Usage |

|---|---|

| Aerospace & Defense | 28% |

| Medical Devices | 24% |

| Automotive | 20% |

| Electronics/Robotics | 15% |

| Others (Tooling, R&D) | 13% |

This demand has led to a surge in local 3D printing service bureaus, research labs, and OEMs investing in metal printers. However, capacity limitations, material quality issues, and long lead times still plague many local providers.

For companies needing reliable, fast-turnaround services, sourcing from global metal AM leaders with scalable infrastructure — such as Metal3DP — is becoming a strategic advantage.

3. Key Considerations for Choosing a Fast Metal AM Supplier in Seoul

Not all 3D printing providers are created equal. In a high-stakes, fast-paced manufacturing environment like Seoul, selecting the right metal additive manufacturing supplier is crucial — especially when turnaround time, dimensional accuracy, and mechanical properties are non-negotiable.

Here are the most critical factors B2B buyers should evaluate:

🧩 1. Turnaround Time Commitment

- Does the supplier offer same-week or 3–7 day delivery options?

- Can they handle urgent production runs without sacrificing quality?

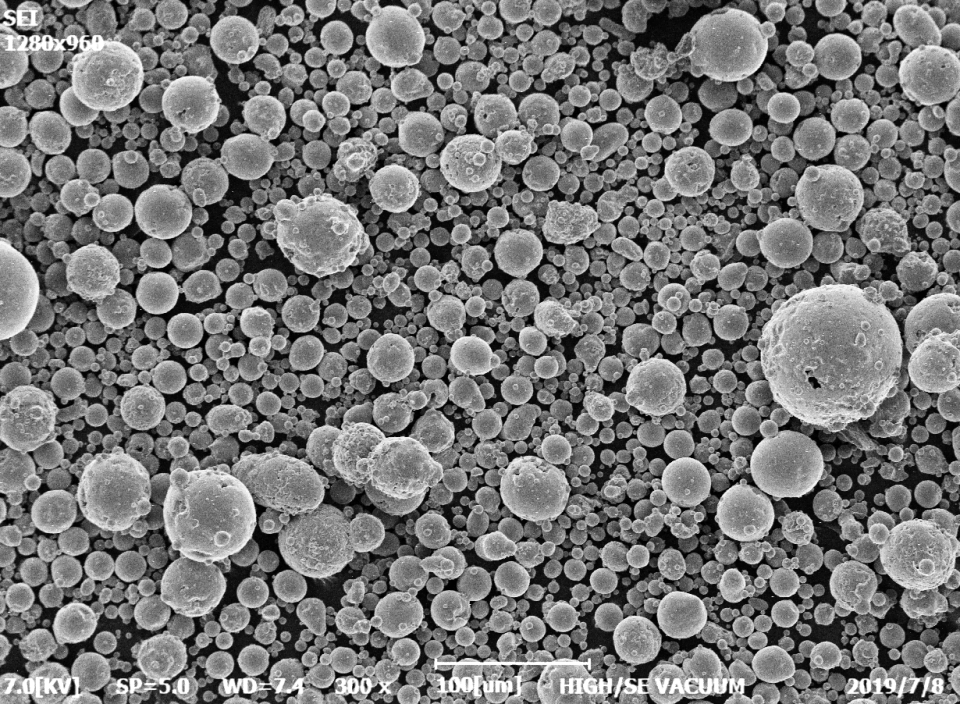

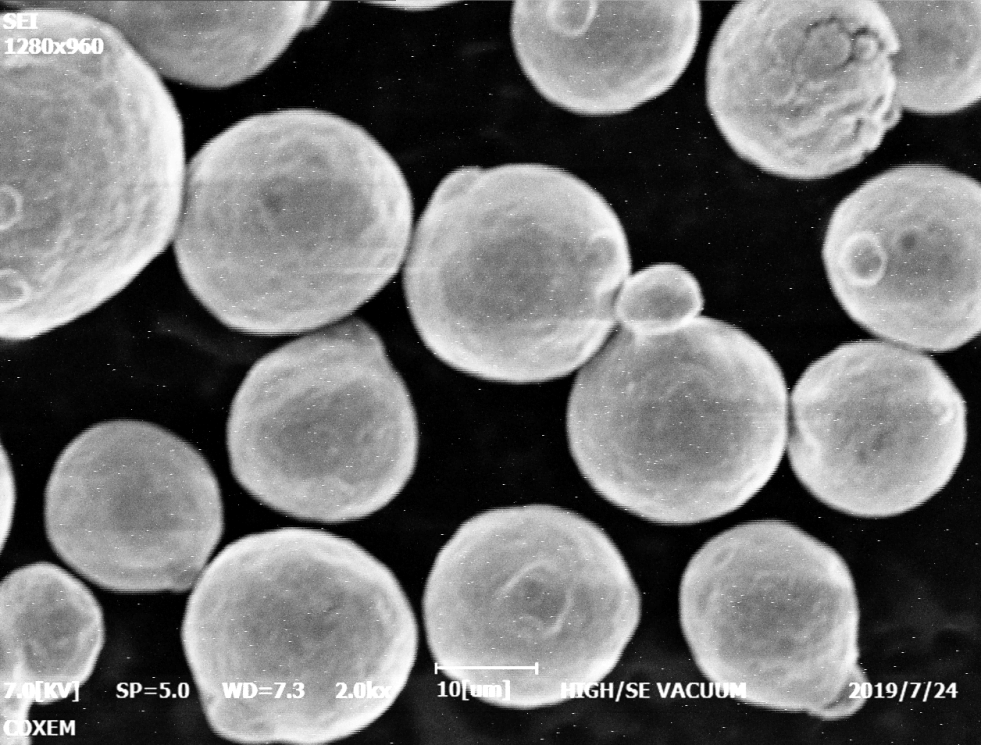

🧩 2. Material Quality & Powder Source

- Is the metal powder spherical and optimized for laser/electron beam PBF?

- Are they using certified, high-purity materials for mission-critical parts?

Metal3DP stands out here by offering high-quality spherical metal powders made using gas atomization and PREP technology. Learn more about our advanced powder systems.

🧩 3. Equipment Capabilities

- What is the build volume and resolution of their metal 3D printers?

- Can they produce large-format or intricate geometries with minimal post-processing?

| Feature | Importance for B2B Buyers |

|---|---|

| Build Volume | Enables larger components or batch printing |

| Resolution (μm) | Affects surface finish and fine details |

| Multi-Laser Support | Speeds up production by parallel printing |

| Inert Gas Environment | Prevents oxidation for reactive metals |

🧩 4. Quality Assurance & Post-Processing

- Does the supplier use CT scanning, tensile testing, or metallurgical inspection?

- Can they offer heat treatment, HIP, or machining for critical components?

🧩 5. Technical Support & Application Engineering

- Do they provide DFAM (Design for Additive Manufacturing) consultation?

- Can they work closely with your team to iterate and optimize part geometry?

🧩 6. Volume Scalability

- Are they able to scale from prototyping to low-volume production?

- Do they offer wholesale or batch order pricing for recurring needs?

Checklist: What to Ask Your AM Supplier

| Question | Why It Matters |

|---|---|

| Can you deliver in under 5 business days? | Ensures your project timeline is met |

| What metal powders do you use? | Impacts part quality and performance |

| Do you offer post-processing services? | Reduces need for multiple vendors |

| Can you help optimize my part design? | Saves cost and improves performance |

| Do you offer volume pricing? | Important for B2B buyers and repeat orders |

If your current AM supplier cannot confidently answer these questions, it may be time to consider a more capable, global partner like Metal3DP.

4. Top 5 Quick-Turnaround Metal Additive Manufacturing Providers in Seoul

Seoul is home to a growing number of additive manufacturing service providers, but only a few specialize in quick-turnaround metal 3D printing services suitable for B2B and industrial applications.

Here’s a curated list of the top 5 providers based on lead time, metal printing capabilities, equipment, and client reviews:

🏆 Top Providers of Rapid Metal AM in Seoul

| Company Name | Specializations | Lead Time | Metal Capabilities | Industry Focus |

|---|---|---|---|---|

| Korea 3D Tech | DMLS, SLM | 3–7 days | Stainless steel, Ti6Al4V, Inconel | Aerospace, Automotive |

| Hankook Precision AM | SLM, EBM | 5–10 days | Titanium, CoCrMo, Superalloys | Medical, Tooling |

| Additive Works Korea | Prototyping + Production | 4–7 days | Aluminum, Nickel alloys | Automotive, Consumer Electronics |

| 3DForge Korea | High-speed prototyping | 3–5 days | Steel, Copper, Titanium | Robotics, Energy |

| KAMTech | Medical metal printing | 7–10 days | Titanium, CoCr | Medical implants, dental |

These companies are focused on serving local clients in Seoul’s metropolitan area. However, they often face challenges that include:

- Limited print volume capacity for large parts

- Delays due to powder imports

- Shortage of multi-laser, high-speed metal printers

- Lack of in-house powder metallurgy R&D

For Korean buyers who need scalable production, premium powder quality, and global experience, working with an international partner like Metal3DP can provide a significant competitive edge.

5. Why More Korean Manufacturers Are Sourcing from International AM Suppliers

Despite South Korea’s domestic advancements, many manufacturers are turning to overseas additive manufacturing partners for several reasons — especially when it comes to time-sensitive projects and high-performance metals.

🌍 Key Advantages of International AM Suppliers

| Advantage | Description |

|---|---|

| Larger Print Capacity | Overseas suppliers often have industrial-scale printers with larger build volumes, enabling batch runs and bigger parts. |

| Superior Metal Powders | Companies like Metal3DP produce powders in-house using advanced atomization systems, ensuring better flowability and sphericity. |

| Material Diversity | Access to a wider range of innovative alloys, including TiTa, TiNbZr, and CoCrMo. |

| Faster Lead Times | International AM bureaus with optimized logistics and digital workflows can deliver in 5–7 days globally. |

| Cost Efficiency | Lower labor and operating costs in regions like China offer competitive rates without sacrificing quality. |

📦 Common Parts Korean Companies Order from Overseas Suppliers

- Aerospace brackets and turbine blade prototypes

- Medical implants and orthopedic trial models

- Customized EV battery casings

- High-conductivity copper heat exchangers

- Tooling inserts with internal cooling channels

Case Study: Korean Robotics OEM Partners with Global AM Supplier

A Seoul-based robotics startup required a batch of 20 lightweight titanium arms for a new robotic arm prototype. Local suppliers quoted 14–18 days for delivery. Instead, they partnered with an overseas AM provider that:

- Offered a 5-day turnaround

- Used PREP-based titanium powder

- Delivered via express logistics with full inspection reports

Result? The startup was able to meet its investor demo deadline and secure Series A funding.

This example illustrates why global sourcing in AM is becoming a strategic lever for Korean manufacturers.

6. Why Choose Metal3DP as Your Trusted Metal AM Supplier

As Korean manufacturers look beyond borders for faster, more reliable metal 3D printing, Metal3DP stands out as a comprehensive solution provider with the right mix of technology, scale, and expertise.

🏭 About Metal3DP

Metal3DP is a China-based leader in industrial metal additive manufacturing, offering:

- High-performance metal 3D printers

- In-house production of spherical metal powders

- Application development and B2B engineering services

With a proven track record in aerospace, medical, and automotive industries, Metal3DP enables Korean clients to:

- Prototype and validate faster

- Scale up to small-batch production

- Access innovative metal alloys at competitive prices

⚙️ What Sets Metal3DP Apart?

| Category | Metal3DP Capabilities |

|---|---|

| Printer Technology | SEBM (Selective Electron Beam Melting), multi-laser PBF |

| Powder Manufacturing | Gas Atomization + PREP for ultra-spherical powders |

| Powder Materials | Ti6Al4V, CoCrMo, TiNbZr, TiTa, AlSi10Mg, Stainless Steels |

| Build Size | Large-volume printers up to 450 mm |

| Application Services | DFAM design, simulation, post-processing, QA |

🌐 Why Korean Buyers Trust Metal3DP

- Fast International Shipping: Express delivery to Seoul in as little as 5–7 days

- Material Innovation: Access to rare and high-performance alloys not available domestically

- Consistent Quality: Integrated powder + printer + process control for repeatable results

- B2B-Focused: OEM-friendly pricing, batch production, and engineering support

- End-to-End Support: From CAD file consultation to post-print heat treatment

Learn more about our complete range of printing methods and technologies and how they meet the needs of modern manufacturing.

📌 Summary: Why Choose Metal3DP for Your Next Project?

- ✅ Trusted by global manufacturers in aerospace, medical, and energy sectors

- ✅ Competitive pricing with no compromise on material quality

- ✅ Quick-turnaround delivery to Seoul and broader South Korea

- ✅ Full service from CAD file to finished metal part

- ✅ In-house expertise in printer, powder, and process integration

If you’re a Korean manufacturer looking for a reliable, fast, and technically advanced AM partner, Metal3DP is your go-to source.

7. How to Order Quick-Turnaround Metal 3D Printing Services from Metal3DP

If you’re a Korean manufacturer, startup, or R&D department looking for a fast and reliable metal 3D printing partner, Metal3DP provides a seamless, B2B-optimized ordering process. Whether you need a single prototype or a batch of production parts, Metal3DP’s streamlined system ensures speed, quality, and transparency at every stage.

📦 Step-by-Step Ordering Process

| Step | Action | Description |

|---|---|---|

| 1 | Submit RFQ | Share your STL/CAD files and project specs via Metal3DP’s Contact Page. |

| 2 | Technical Review | Our engineers review for printability, tolerances, and material compatibility. |

| 3 | Get Quotation | You’ll receive a detailed quote including lead time, material options, and post-processing. |

| 4 | Confirm Order | Approve the quote and initiate production. Payment terms available for bulk/recurring orders. |

| 5 | Production & QA | Your parts are manufactured using Metal3DP’s state-of-the-art SEBM or PBF systems. |

| 6 | Shipping | Parts are packed securely and shipped via express courier to Seoul or any Korean city. |

Typical turnaround time for Korean clients: 5–7 business days including shipping.

🔧 Supported File Types & Materials

- File Formats: STL, STEP, IGES, SolidWorks

- Materials Available: Ti6Al4V, TiTa, CoCrMo, Stainless Steel, Ni-based alloys, Al alloys, and more

- Discover all available powders here: Metal3DP Products

💼 Wholesale & B2B Ordering Options

For larger clients and distributors, Metal3DP offers:

- Batch pricing discounts

- Volume production capabilities

- Private-label manufacturing

- Custom alloy development

Whether you’re in automotive tooling, medical devices, or aerospace prototyping, Metal3DP is equipped to handle your specialized needs with exceptional speed and precision.

8. FAQs: Common Questions About Metal 3D Printing for Korean Manufacturers

❓ Q1: How fast can Metal3DP deliver metal 3D printed parts to Seoul?

Answer: Under normal production conditions, we can complete your parts in 2–3 business days and ship via express air courier. Total lead time is typically 5–7 business days door-to-door.

❓ Q2: What types of metal powders does Metal3DP offer?

Answer: We produce a wide range of spherical metal powders using gas atomization and PREP. All powders are tailored for laser and electron beam powder bed fusion. Available materials include:

- Titanium alloys (Ti6Al4V, TiTa, TiNbZr)

- Cobalt chromium (CoCrMo)

- Superalloys (Inconel, Ni-based)

- Stainless steels

- Aluminum alloys

Explore all our materials here: High-Quality Metal Powders

❓ Q3: Can Metal3DP help optimize my part for additive manufacturing?

Answer: Absolutely. Our engineering team provides DFAM consulting, helping you redesign parts for better performance, reduced weight, and lower cost using additive-friendly geometries.

❓ Q4: Do you offer post-processing like machining or heat treatment?

Answer: Yes. We offer HIP (Hot Isostatic Pressing), heat treatment, surface finishing, and CNC machining as part of our end-to-end service.

❓ Q5: Is Metal3DP familiar with Korean industrial standards?

Answer: Yes. We work with international clients and are experienced in meeting medical, aerospace, and automotive quality standards. Test reports and certificates are provided upon request.

9. Conclusion & Call-to-Action: Power Your Next Project with Metal3DP

Fast-moving industries like aerospace, medical devices, and automotive innovation in Seoul demand a new level of speed and design freedom — and that’s exactly what Metal Additive Manufacturing delivers.

But to make the most of this transformation, you need a partner that offers:

- Speed without compromising on quality

- Material innovation that goes beyond local limitations

- Scalability from prototype to production

- Engineering support that speaks your language

That partner is Metal3DP — a global leader in metal 3D printing solutions.

🔗 Internal Resources to Explore

Here are some helpful links to learn more:

- 📘 About Metal3DP

- ⚙️ Metal 3D Printing Services

- 🧪 Printing Methods

- 🧲 Available Metal Powders & Products

- 🌐 Official Website Homepage

🚀 Ready to accelerate your next metal AM project?

🔧 Request a quote or schedule a consultation today via Metal3DP Contact Page.

Your innovation deserves high-performance, fast-turnaround metal 3D printing — and we’re here to deliver it.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731