CoCrMoW-pulver

CoCrMoW-pulver är ett pulver av legeringen kobolt-krom-molybden-volfram som främst används för tillverkning av ortopediska ledimplantat. Tillsatsen av volfram förbättrar ytterligare hållfastheten, slitstyrkan och hårdheten jämfört med CoCrMo-legeringar.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över CoCrMoW-pulver

CoCrMoW-pulver är ett pulver av legeringen kobolt-krom-molybden-volfram som främst används för tillverkning av ortopediska ledimplantat. Tillsatsen av volfram förbättrar ytterligare hållfastheten, slitstyrkan och hårdheten jämfört med CoCrMo-legeringar.

Viktiga egenskaper och fördelar med CoCrMoW-pulver är bl.a:

Egenskaper och kännetecken för CoCrMoW-pulver

| Fastigheter | Detaljer |

|---|---|

| Sammansättning | Co-Cr-Mo-W-legering |

| Täthet | 9,2 g/cc |

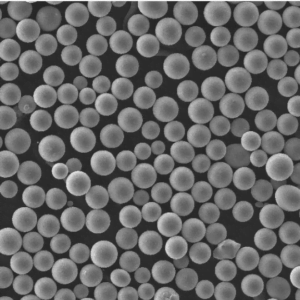

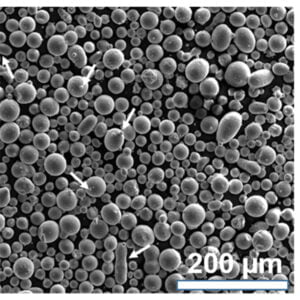

| Partikelns form | Sfärisk |

| Storleksintervall | 15-45 mikrometer |

| Skenbar densitet | Upp till 60% av verklig densitet |

| Flytbarhet | Bra |

| Korrosionsbeständighet | Utmärkt tack vare Cr-oxidskikt |

| Biokompatibilitet | Hög, lämplig för implantat |

| Slitstyrka | Extremt bra från W och Cr |

| Styrka | Mycket hög från solid lösning förstärkning |

Med sin unika kombination av biokompatibilitet, hög hårdhet, styrka och seghet möjliggör CoCrMoW tillverkning av högpresterande ortopediska implantat med hjälp av 3D-printning eller formsprutning av metall.

CoCrMoW pulver sammansättning

CoCrMoW pulver sammansättning

| Element | Vikt % |

|---|---|

| Kobolt | Balans |

| Krom | 26-30% |

| Molybden | 5-7% |

| Volfram | 4-6% |

| Kol | < 0,35% |

| Mangan | < 1% |

| Kisel | < 1% |

| Järn | < 1% |

| Nickel | < 1% |

- Kobolt ger styrka, biokompatibilitet, hjälper till att stärka fasta lösningar

- Krom för oxidations- och korrosionsbeständighet

- Molybden bidrar till förstärkning av solid lösning

- Volfram förbättrar slitstyrkan och hårdheten avsevärt

- Andra grundämnen förekommer som orenheter

Det höga innehållet av Cr, Mo och W ger en utmärkt kombination av styrka, hårdhet och korrosionsbeständighet, vilket krävs för ortopediska implantat.

CoCrMoW-pulver Fysikaliska egenskaper

CoCrMoW-pulver Fysikaliska egenskaper

| Fastigheter | Värden |

|---|---|

| Täthet | 9,2 g/cc |

| Smältpunkt | 1370-1430°C |

| Elektrisk resistivitet | 96 μΩ-cm |

| Termisk ledningsförmåga | 16 W/mK |

| CTE | 14,5 x 10^-6 K^-1 |

| Curie-temperatur | 1160°C |

- Hög densitet jämfört med CoCrMo- och titanlegeringar

- Bibehåller styrka och hårdhet vid förhöjda temperaturer

- Relativt låg värmeledningsförmåga

- Blir paramagnetisk över Curie-temperaturen

- CTE högre än konkurrerande legeringar i implantatapplikationer

Egenskaperna möjliggör användning i lastbärande ortopediska implantat som kräver hållfasthet, hårdhet och korrosionsbeständighet vid höga temperaturer.

CoCrMoW pulver Mekaniska egenskaper

CoCrMoW pulver Mekaniska egenskaper

| Fastigheter | Värden |

|---|---|

| Hårdhet | 43-52 HRC |

| Draghållfasthet | 1310-1650 MPa |

| Sträckgräns | 1035-1450 MPa |

| Töjning | 8-15% |

| Elasticitetsmodul | 240-310 GPa |

| Tryckhållfasthet | 1700-2100 MPa |

- Utmärkt kombination av mycket hög hållfasthet och hårdhet

- Hållfasthetsnivåerna överstiger kraven för lastbärande implantat

- Rimlig duktilitet för ett hårt material

- Hög modul ger den styvhet som krävs för implantat

- Hög utmattningshållfasthet ger lång livslängd

De mekaniska egenskaperna gör CoCrMoW-pulvret mycket lämpligt för tillverkning av starka, slitstarka ortopediska implantat med AM-teknik.

CoCrMoW Pulver Tillämpningar

Primära användningsområden för CoCrMoW-pulver är

CoCrMoW Pulver Tillämpningar

| Tillämpning | Exempel |

|---|---|

| Ortopediska implantat | Knä-, höft- och tandimplantat |

| Medicintekniska produkter | Kirurgiska verktyg och instrument |

| Flyg- och rymdindustrin | Komponenter till flygplansmotorer |

| Fordon | Bränsleinsprutningsdelar, ventiler |

| Industriell | Skärande verktyg, matriser, formar |

Några specifika produktanvändningar av CoCrMoW legeringspulver:

- Ledytor i implantat för ledproteser

- Tandkronor, broar och rotkapslar

- Maxillofaciala implantat, skallplattor

- Turbinblad och höljen till flygplansmotorer

- Ventiler och bränsleinsprutningsmunstycken till bilmotorer

- Skärande verktyg och industriverktyg

Kombinationen av enastående mekaniska egenskaper, korrosionsbeständighet och biokompatibilitet ger maximal prestanda för dessa krävande applikationer.

Specifikationer för CoCrMoW-pulver

Viktiga standarder för CoCrMoW-pulver:

Standarder för CoCrMoW-pulver

| Standard | Beskrivning |

|---|---|

| ASTM F75 | Standard för smidd CoCrMo legering för kirurgiska implantat |

| ASTM F1537 | Smidd CoCrMoNi-legering för dentaltillämpningar |

| ASTM F3001 | Specifikation för additiv tillverkning av medicinska implantat med pulverbäddfusion |

| ISO 5832-4 | Smidd CoCrMoNi-legering för kirurgiska implantat |

Dessa standarder specificerar:

- Gränser för sammansättning, föroreningar

- Minimikrav på mekaniska egenskaper

- Produktionsmetod - atomisering med inert gas

- Acceptabel partikelstorleksfördelning

- Testprotokoll för kvalitetssäkring

- Krav på karaktärisering av pulver

Överensstämmelse med standarder säkerställer lämplighet för kritiska ortopediska implantatapplikationer.

CoCrMoW pulver Partikelstorlek

Fördelning av partikelstorlek för CoCrMoW-pulver

| Partikelstorlek | Egenskaper |

|---|---|

| 15-25 mikrometer | Används i laserpulverbäddfusion (LPBF) |

| 25-45 mikrometer | Används i bindemedelsjetting och DMLS |

| 10-45 mikrometer | Används vid formsprutning av metall |

- Finare pulver ger högre upplösning och ytfinhet för AM

- Grovare pulver har bättre flytbarhet för pulverbearbetning

- Balanserad storleksfördelning optimerad för varje produktionsmetod

- Tät kontroll över partikelstorleksfördelningen bibehålls

Kontroll av partikelstorlek och morfologi möjliggör hög packningstäthet och optimerad sintring.

CoCrMoW pulver skenbar densitet

CoCrMoW pulver skenbar densitet

| Skenbar densitet | Egenskaper |

|---|---|

| Upp till 60% av verklig densitet | För sfärisk pulvermorfologi |

| 4,5-5,5 g/cc-intervall | På grund av tomrum mellan partiklarna |

- Högre skenbar densitet förbättrar pulverflöde och kompressibilitet

- Sfärisk pulverform ger högre packningstäthet

- Värden upp till 65% är möjliga med optimerat pulver

Högre skenbar densitet resulterar i bättre tillverkningsproduktivitet och detaljkvalitet.

CoCrMoW Pulver Produktionsmetod

Produktion av CoCrMoW-pulver

| Metod | Detaljer |

|---|---|

| Atomisering av gas | Inert gas under högt tryck bryter upp smält legeringsström till fina droppar |

| Induktionssmältning i vakuum | Utgångsmaterial med hög renhet smälta under vakuum |

| Flera omsmältningar | Förbättrar den kemiska homogeniteten |

| Siktning | Klassificerar pulver i olika fraktioner av partikelstorlek |

| Blandning | Pulverfraktioner blandade för att anpassa partikelfördelningen |

- Gasatomisering ger fin sfärisk pulvermorfologi

- Vakuumsmältning minimerar orenheter som syre och kväve

- Flerfaldig omsmältning förbättrar jämnheten i sammansättningen

- Efterbearbetning möjliggör exakt kontroll av partikelstorleksfördelningen

Helautomatiserad produktion och strikt processkontroll säkerställer tillförlitliga egenskaper och att pulvret är enhetligt från batch till batch.

Prissättning av CoCrMoW-pulver

Prissättning av CoCrMoW-pulver

| Faktor | Påverkan |

|---|---|

| Pulverkvalitet | Priset ökar med högre renhetsgrad |

| Partikelstorlek | Ultrafina kvaliteter dyrare |

| Orderkvantitet | Prisreduktion för bulkbeställningar |

| Egenskaper för pulver | Högre skenbar täthet kostar mer |

| Förpackning | Argonfyllda behållare höjer priset |

| Krav för testning | Mer rigorösa tester ökar kostnaderna |

| Ledtid | Snabbare leveranstider ökar kostnaderna |

Indikativ prissättning

- CoCrMoW för medicinska tillämpningar: $120-180 per kg

- CoCrMoW för industriella applikationer: $80-120 per kg

Betydligt lägre priser gäller för bulkbeställningar som överstiger flera hundra kilo.

CoCrMoW pulver leverantörer

CoCrMoW pulver leverantörer

| Företag | Plats |

|---|---|

| Snickare Tillsats | USA |

| Sandvik Osprey | STORBRITANNIEN |

| Hoganas | Sverige |

| Praxair | USA |

| AP&C | Kanada |

| Erasteel | Frankrike |

Viktiga urvalsfaktorer:

- Utbud av pulverkvaliteter och partikelstorlekar

- Produktionskapacitet och ledtider

- Pulverets kvalitet och konsistens

- Överensstämmelse med medicinska standarder

- Prissättning och minsta orderkvantitet

- Inspektions-, test- och QA-processer

CoCrMoW Pulverhantering och säkerhet

CoCrMoW Pulverhantering

| Rekommendation | Anledning |

|---|---|

| Undvik inandning | För att förhindra att lungvävnaden skadas av fina partiklar |

| Använd skyddsmask och skyddshandskar | Förhindra oavsiktligt intag genom näsa/mun |

| Hantera i väl ventilerade utrymmen | Minska cirkulationen av luftburna partiklar |

| Använd lämpliga skyddskläder | Minimera hudkontakt |

| Se till att inga antändningskällor finns i närheten | Pulver kan antändas i syrehaltig atmosfär |

| Följ antistatiska protokoll | Förhindra brand på grund av statisk urladdning vid hantering |

| Använd verktyg som inte slår gnistor | Undvik risk för antändning |

| Förvaras i slutna behållare i svalt och torrt utrymme | Förhindrar kontaminering och oxidation |

Även om CoCrMoW-pulver är relativt inert, bör rekommenderade försiktighetsåtgärder vidtas för säker hantering och bearbetning.

Inspektion och provning av CoCrMoW-pulver

Testning av CoCrMoW-pulver

| Test | Detaljer |

|---|---|

| Kemisk analys | ICP-spektroskopi används för att verifiera sammansättningen |

| Analys av partikelstorlek | Bestämmer partikelstorleksfördelningen |

| Skenbar densitet | Mätt med Hall-flödesmätare enligt ASTM B212 |

| Morfologi för pulver | Bildanalys via SEM för att kontrollera partikelform |

| Test av flödeshastighet | Bestämmer flytbarhet genom en standardiserad tratt |

| Tappdensitetstest | Densitet uppmätt efter mekanisk knackning av pulverprov |

Rigorösa tester säkerställer överensstämmelse med specifikationer som ASTM F75 och konsekvent pulver som är lämpligt för tillverkning av ortopediska implantat.

Förvaring och hantering av CoCrMoW-pulver

Förvaring av CoCrMoW-pulver

| Faktor | Effekt |

|---|---|

| Luft, syre | Risk för oxidation vid höga temperaturer |

| Fukt | Låg korrosionshastighet vid rumstemperatur |

| Organiska lösningsmedel | Kan absorbera lösningsmedel och fläckpulver |

| Syror, alkalier | Motståndskraftig mot milda syror och baser |

| Förhöjda temperaturer | Ökad reaktivitet och oxidation i luft |

| Kontaminering | Kan påverka flytbarhet, sintringsförmåga |

Rekommendationer:

- Förvaras förseglade i behållare rensade från inert gas

- Hålla temperaturen under 30°C

- Undvik kontakt med oxiderande syror och klorerade lösningsmedel

- Öppna behållare endast i kontrollerade miljöer

Med rätt försiktighetsåtgärder uppvisar CoCrMoW-pulver utmärkt stabilitet under hantering och lagring.

Jämförelse med CoCrMo-pulver

CoCrMoW vs CoCrMo pulver

| Parameter | CoCrMoW | CoCrMo |

|---|---|---|

| Täthet | 9,2 g/cc | 8,3 g/cc |

| Hårdhet | 43-52 HRC | 35-45 HRC |

| Draghållfasthet | 1310-1650 MPa | 1170-1510 MPa |

| Slitstyrka | Utmärkt | Mycket bra |

| Korrosionsbeständighet | Utmärkt | Utmärkt |

| Biokompatibilitet | Hög | Hög |

| Kostnad | Hög | Måttlig |

| Användningsområden | Ortopediska implantat, flyg- och rymdindustrin | Ortopediska implantat, tandimplantat |

- CoCrMoW har betydligt högre hållfasthet och hårdhet

- CoCrMoW ger bättre slitstyrka

- Båda erbjuder utmärkt korrosionsbeständighet och biokompatibilitet

- CoCrMoW är dyrare på grund av tillsats av W

- CoCrMoW föredras för knä- och höftledsimplantat; CoCrMo för tandvård

Volframtillsatsen ger CoCrMoW överlägsna mekaniska egenskaper jämfört med konventionella CoCrMo-legeringar.

Fördelar och nackdelar med CoCrMoW-pulver

Fördelar med CoCrMoW-pulver:

- Utmärkt hållfasthet, hårdhet och slitstyrka

- Hög biokompatibilitet och korrosionsbeständighet

- Goda egenskaper vid höga temperaturer

- Kan bearbetas via AM- eller MIM-teknik

- Lämplig för lastbärande ortopediska implantatapplikationer

- Ger ett attraktivt estetiskt utseende

Begränsningar för CoCrMoW-pulver:

- Dyrare än pulver av CoCrMo och rostfritt stål

- Lägre duktilitet och brottseghet

- Kräver skyddande atmosfär under bearbetning

- Svårt att bearbeta slutkomponenter

- Begränsad sammanfognings- och svetsbarhet

- Utsläpp av Co-joner väcker oro för hälsan

Vanliga frågor om CoCrMoW-pulver

F: Vilka är de viktigaste användningsområdena för CoCrMoW-pulver?

S: De primära användningsområdena är knä- och höftledsimplantat, dentala restaureringar som kronor och broar, maxillofaciala implantat och komponenter för flyg- och rymdindustrin som turbinblad.

F: Hur förbättrar volframtillsatsen egenskaperna hos CoCrMo-legeringen?

A: Volfram ökar avsevärt hållfastheten, hårdheten och slitstyrkan genom förstärkning i fast lösning och bildning av styva karbider. Detta resulterar i utmärkta prestanda för lastbärande implantat.

F: Vilka försiktighetsåtgärder krävs vid hantering av CoCrMoW-pulver?

A: Rekommenderade försiktighetsåtgärder inkluderar användning av skyddsmask, handskar, kläder, hantering i ventilerade utrymmen, undvikande av antändningskällor, kontroll av statisk urladdning, användning av gnistfria verktyg och förvaring av förseglade behållare på en sval och torr plats.

F: Vilka är de viktigaste skillnaderna mellan CoCrMoW-kvaliteter för medicinskt och industriellt bruk?

S: Medicinska kvaliteter har högre renhet, mindre föroreningar, kontrollerad partikelstorleksfördelning, genomgår mer rigorösa tester och tillverkas under sträng kvalitetskontroll för att uppfylla standarderna för biomedicinska implantat.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731