Single-Furnace VIGA Equipment

Table of Contents

Welcome to the ultimate guide on Single-Furnace VIGA (Vacuum Induction Gas Atomization) Equipment. If you’re delving into the world of advanced metallurgy and metal powder production, you’re in the right place. We’re going to break down everything you need to know about single-furnace VIGA systems, covering their functionality, advantages, applications, and much more.

Overview of Single-Furnace VIGA Equipment

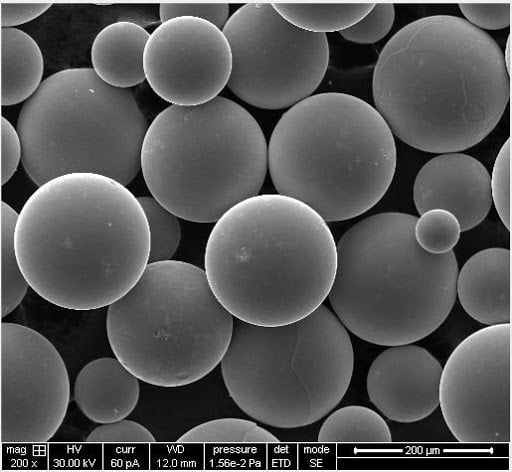

Single-furnace VIGA equipment represents a state-of-the-art method for producing high-quality metal powders. These systems utilize vacuum induction melting combined with gas atomization to create fine, spherical powders with superior properties. This technique is critical for industries requiring precise material characteristics, such as aerospace, automotive, and biomedical sectors.

Types of Metal Powders Produced by Single-Furnace VIGA

Let’s start with a look at some specific metal powder models produced by single-furnace VIGA equipment. Here’s a detailed list to get you acquainted:

| Metal Powder Model | Composition | Key Properties | Applications |

|---|---|---|---|

| 316L Stainless Steel | Fe, Cr, Ni, Mo | Corrosion resistance, high strength | Medical implants, marine equipment |

| 17-4 PH Stainless Steel | Fe, Cr, Ni, Cu, Nb | High strength, corrosion resistance | Aerospace parts, chemical processing |

| Ti-6Al-4V Titanium Alloy | Ti, Al, V | High strength-to-weight ratio, biocompatibility | Aerospace components, medical devices |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Heat resistance, oxidation resistance | Jet engine parts, nuclear reactors |

| Cobalt-Chromium Alloy | Co, Cr, Mo, W | Wear resistance, high hardness | Dental implants, orthopedic devices |

| AlSi10Mg Aluminum Alloy | Al, Si, Mg | Lightweight, good casting properties | Automotive parts, aerospace structures |

| Maraging Steel | Fe, Ni, Co, Mo | High strength, excellent toughness | Tooling, aerospace structures |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Creep strength, thermal stability | Gas turbines, heat exchangers |

| Copper Alloy C18150 | Cu, Cr, Zr | High electrical conductivity, good strength | Electrical components, welding electrodes |

| Nickel Superalloy Nimonic 90 | Ni, Cr, Co, Ti, Al | Oxidation resistance, high temperature strength | Turbine blades, exhaust valves |

Applications of Single-Furnace VIGA Equipment

The versatility of single-furnace VIGA equipment is evident from its broad range of applications. Here are some specific uses:

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Turbine blades, structural components | High strength-to-weight ratio, resistance to high temperatures |

| Automotive | Engine parts, lightweight structures | Improved fuel efficiency, durability |

| Biomedical | Implants, surgical instruments | Biocompatibility, precision |

| Energy | Nuclear reactor components, heat exchangers | Resistance to corrosion and high temperatures |

| Tooling | Molds, dies | Wear resistance, longevity |

| Electronics | Conductive components | High electrical conductivity, reliability |

Detailed Specifications, Sizes, and Standards

Understanding the specifications and standards of metal powders produced by VIGA equipment is crucial for selecting the right material for your needs. Here’s a breakdown:

| Metal Powder Model | Particle Size Range | Standards | Typical Applications |

|---|---|---|---|

| 316L Stainless Steel | 15-45 µm | ASTM F138, ISO 5832-1 | Medical, marine |

| 17-4 PH Stainless Steel | 20-63 µm | AMS 5643, ASTM A693 | Aerospace, chemical |

| Ti-6Al-4V Titanium Alloy | 15-45 µm | ASTM F1472, ISO 5832-3 | Aerospace, medical |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Jet engines, nuclear |

| Cobalt-Chromium Alloy | 10-50 µm | ASTM F1537, ISO 5832-12 | Dental, orthopedic |

| AlSi10Mg Aluminum Alloy | 20-60 µm | ISO 3522, ASTM B85 | Automotive, aerospace |

| Maraging Steel | 10-45 µm | AMS 6514, ASTM A538 | Tooling, aerospace |

| Haynes 282 | 20-53 µm | AMS 5918, ASTM B637 | Gas turbines, heat exchangers |

| Copper Alloy C18150 | 15-45 µm | ASTM B820, AMS 4596 | Electrical, welding |

| Nickel Superalloy Nimonic 90 | 20-53 µm | AMS 5829, ASTM B637 | Turbine blades, exhaust valves |

Suppliers and Pricing Details

When it comes to purchasing metal powders produced via single-furnace VIGA equipment, knowing your suppliers and pricing is key. Here’s a list of some prominent suppliers and their approximate pricing:

| Supplier | Metal Powder Models | Pricing (per kg) | Additional Services |

|---|---|---|---|

| Höganäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Custom sizing, technical support |

| Carpenter Technology | 17-4 PH, Maraging Steel | $60-$250 | Metallurgical consulting, custom alloys |

| Sandvik | Cobalt-Chromium, Haynes 282 | $80-$300 | Quality testing, R&D support |

| LPW Technology | AlSi10Mg, Copper Alloy C18150 | $40-$150 | Powder lifecycle management, traceability |

| AP&C (GE Additive) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Advanced characterization, recycling services |

| Praxair Surface Technologies | Inconel 718, Nimonic 90 | $70-$280 | Application engineering, coating solutions |

Advantages and Disadvantages of Single-Furnace VIGA Equipment

Let’s delve into the pros and cons of using single-furnace VIGA systems for metal powder production:

| Advantages | Disadvantages |

|---|---|

| High Purity: The vacuum environment minimizes contamination. | Cost: High initial investment and operational costs. |

| Uniform Particle Size: Consistent powder quality. | Complexity: Requires skilled operators and maintenance. |

| Versatility: Suitable for a wide range of metal alloys. | Energy Consumption: Significant power usage. |

| Improved Material Properties: Enhanced mechanical properties of powders. | Limited Capacity: Single furnace limits production volume compared to multi-furnace setups. |

FAQs

| Question | Answer |

|---|---|

| What is single-furnace VIGA equipment used for? | It is used for producing high-quality metal powders for various industries like aerospace, automotive, and biomedical. |

| How does single-furnace VIGA equipment work? | It uses vacuum induction melting combined with gas atomization to produce fine, spherical metal powders. |

| What are the benefits of using VIGA for metal powder production? | Benefits include high purity, uniform particle size, and improved material properties. |

| What metals can be processed using VIGA equipment? | A wide range including stainless steels, titanium alloys, nickel superalloys, and more. |

| Are there any limitations to using single-furnace VIGA equipment? | Yes, including high cost, complexity, and limited production capacity. |

| Which industries benefit most from VIGA-produced powders? | Aerospace, automotive, biomedical, energy, tooling, and electronics industries. |

| What are the typical particle sizes for VIGA-produced powders? | Particle sizes typically range from 10 to 63 microns, depending on the alloy and specific requirements. |

| How does VIGA compare to other powder production methods? | VIGA offers higher purity and better control over particle size but can be more expensive and complex than other methods like water atomization. |

Conclusion

Single-furnace VIGA equipment is a game-changer in the field of metal powder production, offering unparalleled purity, consistency, and versatility. Whether you’re working in aerospace, automotive, or biomedical industries, understanding the intricacies of VIGA technology can help you make informed decisions and leverage the benefits of high-quality metal powders.

If you have any more questions or need specific information, feel free to reach out. Dive into the world of advanced metallurgy with single-furnace VIGA equipment and elevate your material capabilities to new heights!

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731