Tantalum Medical Implants Manufacturing in South Korea: A Comprehensive Guide for B2B Buyers

Table of Contents

1. Introduction: The Growing Demand for Tantalum Medical Implants

Tantalum is emerging as a preferred material for medical implants due to its biocompatibility, corrosion resistance, and mechanical strength. These properties make it ideal for orthopedic, dental, and cardiovascular implants.

Why Tantalum for Medical Implants?

- Biocompatibility: Tantalum is highly resistant to body fluids, reducing the risk of rejection.

- Osseointegration: It promotes bone growth, making it ideal for orthopedic applications.

- Corrosion Resistance: Unlike titanium, tantalum does not corrode in the human body.

- High Strength: Suitable for load-bearing implants such as hip and knee replacements.

Applications of Tantalum Implants

| Category | Example Applications |

|---|---|

| Orthopedic | Hip and knee replacements, spinal implants |

| Dental | Dental implants, bone grafting materials |

| Cardiovascular | Stents, pacemaker electrodes |

As the South Korean medical sector advances, the demand for high-quality tantalum implants is rising. This blog explores the market trends, key suppliers, and how to source these implants efficiently.

2. Market Trends & Growth Potential in South Korea

South Korea’s Medical Device Market

South Korea is one of the leading markets for medical device manufacturing. The country boasts a highly advanced healthcare system, strong research institutions, and a growing demand for biocompatible implant materials.

Market Growth Factors

- Aging Population: South Korea has one of the fastest-aging populations in the world, increasing the need for orthopedic and dental implants.

- Government Support: The South Korean government encourages medical technology innovation through funding and subsidies.

- Advancements in 3D Printing: The rise of 3D-printed tantalum implants is transforming the industry.

Tantalum’s Competitive Edge Over Titanium and Other Metals

| Feature | Tantalum | Titanium | Stainless Steel |

|---|---|---|---|

| Biocompatibility | Excellent | Good | Moderate |

| Corrosion Resistance | Excellent | Good | Low |

| Osseointegration | High | Moderate | Low |

| Strength | High | High | Moderate |

With higher biocompatibility and superior mechanical properties, tantalum is increasingly replacing titanium in hip, knee, and spinal implants.

3. Key Factors to Consider When Choosing a Tantalum Implant Supplier

Choosing the right tantalum implant supplier is crucial for ensuring quality, reliability, and regulatory compliance. Here are key factors to consider:

1. Material Quality & Certification

Look for suppliers that provide medical-grade tantalum with certifications such as:

- ISO 13485 (Medical Device Quality Management)

- FDA Approval

- CE Marking

2. Manufacturing Capabilities

Suppliers should have advanced manufacturing technologies, including:

- 3D printing for custom implants

- Vacuum sintering for high-purity tantalum

- Precision machining

3. Scalability and Lead Times

For large-scale orders, ensure the supplier can meet bulk production demands while maintaining consistent quality.

4. Customization & R&D Support

If you require customized implants, choose a supplier with strong R&D capabilities. 3D printing technology is revolutionizing the implant industry, allowing for patient-specific solutions.

5. Pricing & Bulk Order Discounts

Compare pricing structures and inquire about bulk discounts for wholesale orders. Reliable suppliers offer transparent pricing and cost-effective solutions.

| Factor | Why It’s Important |

|---|---|

| Material Certification | Ensures compliance with medical standards |

| Manufacturing Capability | Impacts product quality and customization options |

| Scalability | Determines ability to meet bulk orders |

| Customization | Essential for patient-specific implants |

| Price & Discounts | Affects cost-effectiveness for large-scale buyers |

4. Top Tantalum Medical Implant Manufacturers in South Korea

South Korea has a rapidly growing medical device industry, with several key manufacturers specializing in tantalum medical implants. Below are some of the leading suppliers known for their quality, innovation, and compliance with global medical standards.

Leading Tantalum Implant Manufacturers in South Korea

| Company Name | Specialization | Key Strengths |

|---|---|---|

| Korea Medical Devices Co. | Orthopedic and dental implants | FDA-approved, ISO 13485 certified |

| MedTech Korea | 3D printed tantalum implants | Advanced additive manufacturing technology |

| BioTantalum Inc. | Custom cardiovascular and orthopedic implants | Focus on biocompatibility and patient-specific designs |

| NanoMed Korea | Nano-coated tantalum implants | Specializes in anti-corrosion coatings |

| Metal3DP | High-precision 3D printing of tantalum medical implants | Industry-leading metal powder and AM technology |

Key Considerations When Choosing a Manufacturer

- Regulatory Compliance: Ensure the manufacturer meets ISO 13485, FDA, and CE Marking standards.

- Production Technology: Look for 3D printing capabilities to manufacture customized, high-precision implants.

- Supply Chain Reliability: Choose manufacturers with a proven track record of delivering high-quality implants on time.

- Bulk Order Capability: If you require wholesale orders, ensure the manufacturer has scalability.

5. Why More Medical Companies Are Choosing 3D Printed Tantalum Implants

The Rise of 3D Printing in Medical Implants

Traditional manufacturing methods such as casting and machining have limitations in creating complex, patient-specific implants. 3D printing (Additive Manufacturing) is revolutionizing the industry by enabling:

- Customization of implants based on patient anatomy

- Lattice structures for improved osseointegration

- Reduced material waste and faster production cycles

Advantages of 3D Printed Tantalum Implants

| Feature | Traditional Manufacturing | 3D Printing (Additive Manufacturing) |

|---|---|---|

| Customization | Limited | Fully customizable to patient needs |

| Production Time | Longer due to machining | Faster, direct digital fabrication |

| Osseointegration | Moderate | High due to porous structures |

| Material Waste | High | Low, only material needed is used |

| Complexity | Limited | Can produce intricate geometries |

Why Medical Companies Are Switching to 3D Printing

- Patient-Specific Solutions: Custom implants tailored to individual bone structures improve surgical outcomes.

- Improved Bone Integration: Porous tantalum structures created via 3D printing enhance bone in-growth.

- Faster Production & Reduced Costs: Elimination of expensive machining processes helps cut costs.

6. Why Choose Metal3DP as Your Tantalum Implant Supplier?

Metal3DP is a leading provider of additive manufacturing solutions, specializing in high-performance metal powders and 3D printing technologies. Our expertise in metal additive manufacturing makes us the perfect choice for tantalum medical implants.

Key Reasons to Choose Metal3DP

1. Industry-Leading 3D Printing Technology

We utilize Selective Electron Beam Melting (SEBM) and Laser Powder Bed Fusion (LPBF) to create high-precision, medical-grade tantalum implants.

- Superior print accuracy

- High mechanical strength

- Advanced lattice structures for osseointegration

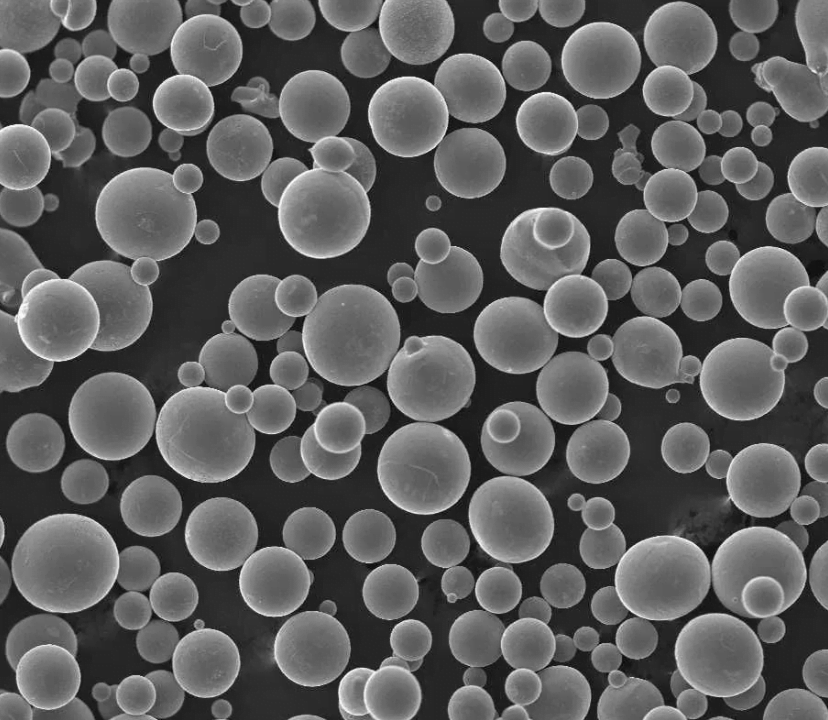

2. High-Quality Tantalum Powder for Medical Applications

Our gas atomized tantalum powders are optimized for 3D printing and medical applications.

- High sphericity for smooth powder flow

- Excellent purity for biocompatibility

- Optimized particle size distribution for precision printing

🔗 Learn more about our metal 3D printing technology here.

3. Customization & Bulk Manufacturing Capabilities

We offer customized implant designs based on patient CT scans, ensuring perfect anatomical fit. Our large-scale production facilities can handle bulk orders for hospitals, distributors, and implant manufacturers.

4. Regulatory Compliance & Medical Industry Expertise

Metal3DP ensures that all materials and manufacturing processes comply with:

- ISO 13485 Medical Device Standard

- FDA & CE Certification Requirements

- Industry-leading testing protocols for biocompatibility

🔗 Explore our printing methods for medical implants here.

5. Competitive Pricing & Reliable Global Supply Chain

We offer cost-effective pricing for bulk orders while ensuring on-time delivery to global customers.

| Feature | Metal3DP Advantage |

|---|---|

| 3D Printing Technology | Industry-leading SEBM & LPBF |

| Tantalum Powder Quality | High sphericity & purity |

| Customization | Patient-specific implants |

| Bulk Manufacturing | Scalable production |

| Regulatory Compliance | ISO 13485, FDA, CE Marking |

7. How to Order Wholesale Tantalum Medical Implants from South Korea

If you’re looking to source high-quality tantalum medical implants in bulk from South Korea, it’s important to follow a structured process to ensure product quality, regulatory compliance, and cost efficiency.

Step-by-Step Guide to Ordering Tantalum Medical Implants

Step 1: Define Your Requirements

Before reaching out to suppliers, determine:

- Types of implants needed (e.g., orthopedic, dental, cardiovascular)

- Customization requirements (e.g., patient-specific designs, porous structures)

- Order quantity (small batch or large-scale production)

- Regulatory compliance needs (e.g., ISO 13485, FDA, CE Marking)

Step 2: Research and Shortlist Reliable Suppliers

Look for reputable manufacturers in South Korea with:

- ISO-certified production facilities

- Proven expertise in tantalum and 3D printing technologies

- Experience with international exports

🔗 Learn more about Metal3DP’s expertise in additive manufacturing here.

Step 3: Request Samples & Verify Quality

Before committing to a bulk order, request sample implants to evaluate:

- Material purity and quality

- Surface finish and mechanical properties

- Osseointegration capability

Step 4: Confirm Pricing & Payment Terms

- Discuss bulk order discounts and long-term supply agreements.

- Ensure transparent pricing with no hidden costs.

- Choose favorable payment terms (e.g., L/C, T/T, PayPal for smaller orders).

Step 5: Place Your Order & Ensure Regulatory Compliance

- Submit purchase order (PO) with all specifications.

- Ensure the supplier provides certifications and compliance documents.

- Confirm shipping timelines and logistics arrangements.

Step 6: Arrange Shipping & Import Documentation

For global buyers, consider:

- Air freight for urgent orders

- Sea freight for cost-effective bulk shipments

- Customs clearance and import regulations in your country

| Order Process Step | Key Considerations |

|---|---|

| Define Requirements | Implant type, customization, regulatory needs |

| Find Reliable Suppliers | ISO-certified, experienced in exports, quality assurance |

| Request Samples | Verify biocompatibility and mechanical properties |

| Confirm Pricing | Bulk discounts, transparent pricing, payment terms |

| Place Order | Ensure compliance, review certifications |

| Arrange Shipping | Choose air/sea freight, manage customs clearance |

🔗 Explore our tantalum implant product line here.

8. FAQs: Common Questions About Buying Tantalum Medical Implants

Q1: Why is tantalum preferred over titanium for medical implants?

Tantalum offers superior biocompatibility, corrosion resistance, and osseointegration compared to titanium. It is particularly beneficial for orthopedic and dental implants requiring enhanced bone in-growth.

Q2: What certifications should I look for in a tantalum implant supplier?

Ensure the supplier complies with:

- ISO 13485 (Medical Device Quality Management System)

- FDA Approval (for US markets)

- CE Marking (for European markets)

Q3: Can tantalum implants be customized for specific patients?

Yes, 3D printing technology allows for patient-specific implant designs, improving surgical success rates.

🔗 Learn more about our advanced 3D printing methods here.

Q4: What is the minimum order quantity (MOQ) for wholesale tantalum implants?

MOQ varies depending on the supplier. Metal3DP offers flexible order sizes, from small batches to large-scale production.

Q5: How long does it take to manufacture and deliver bulk orders?

Production time depends on:

- Order size

- Customization requirements

- Shipping method (air vs. sea freight)

Typically, standard orders take 4-8 weeks, while customized implants may take longer.

Q6: How does Metal3DP ensure the quality of tantalum implants?

Metal3DP employs:

- Gas atomization for high-purity tantalum powders

- Selective Electron Beam Melting (SEBM) and LPBF for precision 3D printing

- Stringent quality control and certification compliance

9. Conclusion: Partner with Metal3DP for High-Quality Tantalum Implants

South Korea is emerging as a key player in tantalum medical implant manufacturing, with advanced 3D printing capabilities revolutionizing the industry. As the demand for biocompatible and high-performance implants continues to grow, sourcing from a trusted supplier is essential.

Why Metal3DP is Your Best Choice for Tantalum Medical Implants

✅ Industry-leading additive manufacturing technology

✅ High-purity tantalum powders optimized for medical applications

✅ Customizable implant designs for patient-specific cases

✅ ISO/FDA/CE-certified production processes

✅ Scalable manufacturing for bulk orders and global distribution

Get in Touch with Metal3DP Today!

Looking for a reliable tantalum implant supplier? Contact Metal3DP for wholesale orders, customized solutions, and expert consultation.

🔗 Visit our website for more details: https://met3dp.com/

📩 Contact Us: Reach out to our sales team for pricing and order inquiries.

By following this guide, medical device distributors, hospitals, and implant manufacturers can confidently source high-quality tantalum medical implants from South Korea. Partner with Metal3DP today to experience the future of medical implant technology!

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731