The Environmental Impact of 3D Printing Metal Powder

Table of Contents

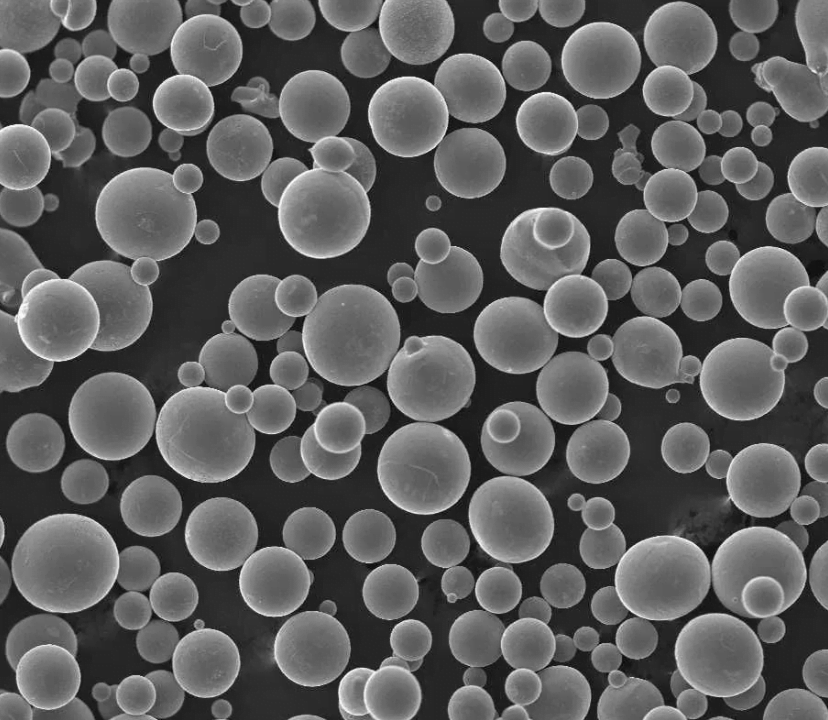

Imagine a world where complex metal parts materialize from a bed of shimmering dust, revolutionizing manufacturing. This is the alluring promise of 3D printing with metal powder. But like any powerful technology, it waltzes with a complex environmental partner. Let’s delve into the intricate dance between 3D printing metal powder and our planet, exploring both its potential for sustainability and the environmental concerns that need to be addressed.

The Environmental Impact of 3D Printing Metal Powder

The environmental impact of 3D printing metal powder isn’t a singular, menacing giant. It’s more like a multifaceted diamond, each facet reflecting a different aspect of the issue. Here, we’ll break down the key areas of concern:

- Dust Pollution: Metal powders are incredibly fine, akin to flour. During printing and handling, these tiny particles can become airborne, posing a health risk to workers and potentially polluting the surrounding environment. Imagine inhaling microscopic metal flakes – not exactly a recipe for a healthy respiratory system.

- Water Pollution: Wastewater from the printing process can contain traces of metal particles and other contaminants. If not properly treated, this wastewater can end up in rivers and streams, disrupting delicate ecosystems. Think of it like a single drop of ink staining a pristine white tablecloth – the impact might be small, but it can spread and cause harm.

- Solid Waste: Unlike traditional manufacturing, which often generates significant scrap metal, 3D printing boasts a reputation for material efficiency. However, unused metal powder and support structures used during printing still contribute to solid waste. It’s a bit like leftover ingredients after baking a cake – you might not throw away the entire batter, but there’s still waste to manage.

The Balancing Act: Advantages We Can’t Ignore

Before we paint 3D printing metal powder as the environmental villain, let’s acknowledge the potential benefits it offers:

- Reduced Material Waste: Compared to traditional subtractive manufacturing techniques like machining, 3D printing often uses less material overall. Imagine carving a intricate sculpture from a block of wood versus building it layer-by-layer with only the necessary material – that’s the essence of material efficiency in 3D printing.

- Lightweight Designs: 3D printing allows for the creation of complex, lightweight structures. This translates to lighter airplanes, cars, and other products, leading to reduced fuel consumption and lower emissions. Think of it like a bird’s feather – lightweight yet incredibly strong – that’s the kind of design flexibility 3D printing offers.

- On-Demand Manufacturing: 3D printing allows for localized production, potentially reducing the need for long-distance transportation and its associated carbon footprint. Imagine printing a spare part on-site instead of shipping it across continents – that’s the potential for a more streamlined and environmentally conscious supply chain.

Finding the Sweet Spot: Measures to Minimize Environmental Impact

The key to a sustainable future with 3D printing metal powder lies in mitigating its environmental downsides. Here are some promising approaches:

- Improved Powder Handling: Developing enclosed printing systems with efficient dust filtration can significantly reduce the risk of airborne metal particles. Imagine a high-tech dustbuster specifically designed for capturing these tiny metal flecks.

- Wastewater Treatment: Implementing robust wastewater treatment systems specifically designed for metal-laden water can ensure that contaminants don’t enter our waterways. Picture a sophisticated filtration system that acts like a bodyguard for our rivers and streams.

- Powder Recycling: Research into efficient metal powder recycling technologies is crucial. Imagine giving leftover metal powder a second life, just like we recycle aluminum cans – it’s a closed-loop system that minimizes waste.

- Sustainable Metal Sources: Sourcing metal powders from ethically mined and recycled materials can significantly reduce the environmental impact of the entire process. Picture using responsibly sourced ingredients for a delicious meal – it’s about ethical manufacturing practices.

FAQ

| Question | Answer |

|---|---|

| Is 3D printing metal powder safe? | With proper safety protocols and equipment, 3D printing metal powder can be safe. However, proper ventilation and dust collection systems are crucial to minimize exposure to metal particles. |

| Can metal powder from 3D printing pollute the environment? | Yes, if not handled and disposed of properly, metal powder can pollute air and water sources. Responsible waste management and wastewater treatment are essential. |

| Is 3D printing metal powder better for the environment than traditional manufacturing? | It depends. While 3D printing can offer reduced material waste and lighter designs, the environmental impact also depends on factors like energy consumption and powder recycling practices. |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731