Metal Powder 3D Printers

Table of Contents

Overview

Metal powder 3D printers use a laser or electron beam to selectively melt and fuse metallic powder into a solid 3D object. This additive manufacturing technology enables complex geometries and lightweight parts to be created directly from 3D CAD data.

Compared to traditional subtractive methods like CNC machining, metal 3D printing can construct intricate designs without the typical constraints of tool access or high part counts from assembly. It provides design freedom and reduced time-to-market for lightweight components across aerospace, automotive, medical, and general industrial applications.

However, the process can be slower and more expensive per part depending on volume requirements. Achieving dense, void-free components with the desired mechanical properties requires optimizing multiple printing parameters and post-processing steps.

Types of Metal Powder 3D Printers

There are two main technologies used in metal powder bed fusion – Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). The key differences lie in the heat source, atmospheric conditions, powder options, and applications:

| Parameter | DMLS | EBM |

|---|---|---|

| Heat Source | Fiber laser | Electron beam |

| Atmosphere | Inert argon | Vacuum |

| Materials | Al, Ti, Ni alloys, tool steels | Ti alloys, some Ni alloys |

| Resolution | Higher, thin walls down to 0.3mm | Moderate, minimum wall 0.8mm |

| Accuracy | ± 0.1-0.2% with 20-50 micron detail | ± 0.2% with 50-200 micron detail |

| Surface Finish | Smooth as-printed surface | Comparatively rough surface |

| Speed | Moderate build rates | Very fast build rates |

| Applications | Dental, medical, aerospace components | Orthopedic implants, aerospace structures |

DMLS Printers use a high power fiber laser precisely controlled by galvo scanners or mirrors to selectively melt microscopic layers of metallic powder in an inert argon atmosphere. Complex and delicate structures with finer details can be produced to a high accuracy and smooth surface finish.

Popular DMLS systems include the EOS M series, GE Additive Concept Laser machines, Renishaw RenAM 500 quad laser printer, and the open-source Lulzbot TAZ Pro.

EBM Printers harness an electron beam as the high intensity heat source to fully melt metal powder layers in a vacuum. The fast scanning beam enables very high build rates, but coarser resolution around 100 microns.

EBM can efficiently print porous structures used as bone implants. Leading EBM systems are manufactured by ARCAM, now a GE Additive brand, which builds the Arcam EBM Spectra H, Q10plus, and Q20plus printers.

Metal Powder Materials

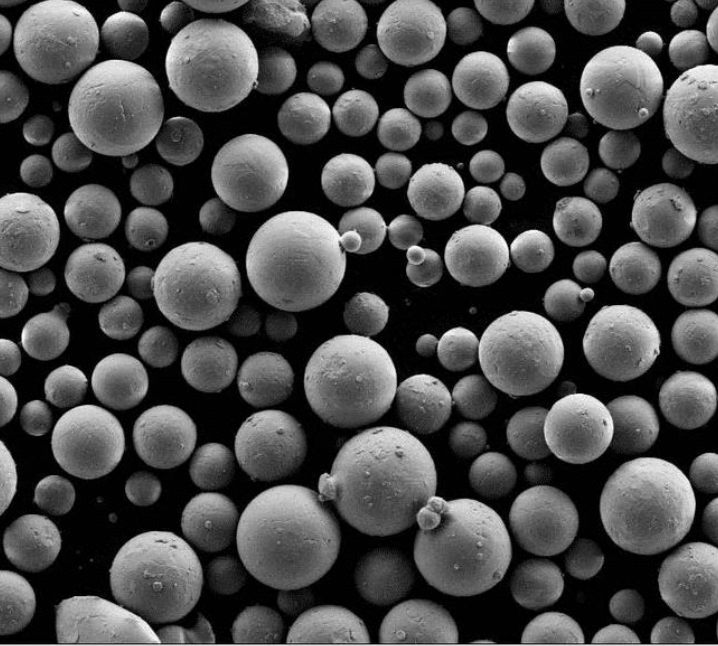

Most commercial metal powders for powder bed 3D printing meet the following specifications:

| Parameter | Typical Range |

|---|---|

| Particle size | 10 – 45 microns |

| Flowability | Suitable for layer deposition |

| Purity | >99.5% |

| Shape | Spherical, Satellite, Irregular |

| Apparent density | 60-80% of solid density |

| Tap density | Up to 98% solid density after compaction |

Common alloys used are titanium, aluminum, stainless steel, nickel superalloys, and cobalt-chrome. Many are customized for AM processes and optimized after repeated recycling.

Grade 5 titanium Ti6Al4V is popular for its strength-to-weight ratio and biocompatibility. Aluminum AlSi10Mg alloy and maraging steel components have high strength. Cobalt chrome is used extensively for dental and medical implants.

Nickel superalloys like Inconel 718 and 625 offer excellent heat and corrosion resistance at high temperatures. Tool steels can be hardened after printing to 60 HRC for extreme wear resistance.

Exotic metal powders are being qualified as the technology expands – aluminum-magnesium-scandium, copper-nickel-tin, precious metals like gold, platinum and silver have been printed.

Printing Process

Though DMLS and EBM vary in hardware, the generic metal powder bed fusion steps are:

- 3D CAD model designed accounting for AM design principles

- STL file processed through slicing software

- Powder deposition mechanism spreads measured layer

- Laser or ebeam scans slice pattern according to file

- Process repeats until full object is built on a baseplate

- Excess powder supports part and absorbs stresses

- Printer recovers unmelted powder for reuse after filtration

- Completed 3D printed build removed from machine

For metals, the following post-processing is critical prior to putting a part in service:

- Support removal via cutting, blasting, or chemical dissolution

- Hot isostatic pressing to eliminate internal voids

- Heat treatments for altering microstructure

- Surface finishing – bead blasting, grinding, polishing

- Precision machining to meet tolerance requirements

- Quality checks per application – dimensional accuracy, density, mechanical properties, microstructure, surface defects

3D printing metals opens up key applications due to:

Design Complexity – intricate cooling channels, lattices, bionic shapes

Customization – patient-specific implants, tailored alloys

Weight Reduction – lighter aero and auto components

Part Consolidation – integrated assemblies printed as one part

Rapid Prototyping – faster iteration of designs

Pros and Cons of Metal 3D Printing

| Advantages | Disadvantages |

|---|---|

| Design freedom for complex, organic shapes | Relatively slow build speeds |

| Lightweighting by optimizing mass distribution | Limitations on part size based on printer model |

| Faster time-to-market of products | Currently expensive technology for production |

| Customization and personalization | Extensive post-processing required |

| High strength and hardness attainable | Anisotropic material properties |

| Intricate lattice and foam structures | Must design to accommodate AM principles |

Buyers Guide – Metal Powder Bed 3D Printers

Choosing the best metal powder bed fusion 3D printing system for industrial manufacturing depends on:

1) Build Envelope: Maximum part dimensions – popular sizes from 100-500mm cubes

2) Laser / Electron Beam: Power rating from 50W-5kW; higher power enables faster builds

3) Materials: Cost, mechanical requirements, ease of post-processing, certification levels

4) Accuracy/Surface Finish: Dimensional precision and tolerances achievable; target roughness

5) Automation: Powder handling systems, sieving, recycling, and controls software

6) Price: Equipment cost ranging from $100k to over $1M; consider operating costs

7) Lead Time + Service: Install schedules from vendors; access to applications expertise

| Specification | Beginner | Professional | Industrial |

|---|---|---|---|

| Build Volume | 5 x 5 x 5 inches | 10 x 10 x 12 inches | 750 x 380 x 380 mm |

| Laser Power | 100-200 W | 400-500 W | 1 kW |

| Layer Height | 20-50 μm | 20-30 μm | 20-50 μm |

| Materials | stainless steels | ~10 metal options | Ti, Al, Ni alloys, more |

| Accuracy | ± 0.5-1 mm | ± 0.1-0.2 mm | ± 0.075-0.2 mm |

| Surface Roughness | 15 μm Ra | 7-10 μm | 5-15 μm |

| Automation | Manual powder handling | Automated depowdering | Closed-loop powder processing |

| Price Range | $100-250K | $300-750K | Over $1 million |

Applications of Metal 3D Printing

Aerospace

- Lightweighted aerostructures and components – titanium and aluminum alloys

- Integrated assemblies consolidated into one printed part

- Complex engine sections with conformal cooling channels

- Quick prototypes for design validation

Medical Devices

- Custom cranial, spinal, and orthopedic implants – titanium and cobalt chrome

- Bio-models for surgical planning and guides

- Patient matching implants and instrumentation

Automotive

- Lightweight chassis and structural parts in aluminum and steel

- Personalized automotive components

- Complex parts consolidation – engine blocks with cooling

Industrial Manufacturing

- Lightweighting components and structural optimization

- Part consolidation to improve functionality

- On-demand spare parts with reduced lead times

- Metal injection molding tooling inserts with conformal cooling

Suppliers of Metal Powder Bed 3D Printers

| Manufacturer | Models | Description |

|---|---|---|

| GE Additive | Concept Laser M2, Mlab, Xline 2000R | Laser powder bed printers acquired from Concept Laser |

| 3D Systems | DMP Flex 350, Factory 500 | Laser melting printers for metals with dual lasers |

| Renishaw | RenAM 500M | Modular laser system with quad laser configuration |

| SLM Solutions | SLM 280 2.0, SLM 500 HL | Selective laser melting machines, pioneers in powder bed fusion |

| Trumpf | TruPrint 3000 | Automated laser metal 3D printer series made in Germany |

| AddUp | FormUp 350 | Modular, double laser printer targeting aerospace |

| Sisma | Sisma MYSINT100 | Low-cost introductory metal laser melting system |

| Additive Industries | MetalFAB1 | High productivity metal AM system for series production |

| OR Laser / Matsuura | LUMEX Avance-25 | Hybrid subtractive + laser metal 3D printer |

| Mazak | INTEGREX i-AM | Done-in-one hybrid metal 3D printer with milling |

| DMG Mori | Lasertec 12 SLM | Powder nozzle + Laser metal 3D printer + 5 axis milling |

| ARCAM / GE Additive | Arcam Q20plus | EBM technology printer for orthopedic implants |

| Velo3D | Sapphire | SupportFree metal printer for low angle features |

| Desktop Metal | Production System | Binder jetting + sintering workflow for metal 3D printing |

| Markforged | Metal X | Bound metal deposition printer affordable for workshops |

| Tiertime | UP300M | Laser powder bed fusion machine ‘made in China’ |

| Farsoon | FS721M | Industrial grade metal powder bed system |

| 3DGence | DOUBLE P255 | Laser & EBM metal printer combo hybrid system |

| Aidro | hydrim M3 | Multi-laser metal printer focused on hydraulics |

| Aurora Labs | RMP-1 | Multi-laser printer targeting high throughput |

Metal Powder for 3D Printing – Suppliers

| Company | Products | Description |

|---|---|---|

| AP&C | Titanium, nickel, cobalt alloys | Powders for aerospace and medical |

| Carpenter Additive | 17-4PH, 316L, cobalt chrome, Inconel | Broad portfolio of 3D printing alloys |

| Sandvik Osprey | Ti6Al4V, stainless steels, Ni alloys | Spherical powders customized for AM |

| Praxair | Titanium, nickel, tool steel alloys | High purity reactive and refractory metals |

| LPW Technology | Aluminum alloy powders | Specialists in aluminum materials |

| Höganäs | Stainless steels, soft magnetic alloys | Shaped metal powders from atomization |

| EOS | EOS MaragingSteel MS1, StainlessSteel 316L | Materials and parameters from system OEM |

Cost Analysis

Like most additive technologies, metal powder bed fusion is currently more expensive for individual parts produced compared to conventional mass manufacturing.

However, it offers cost savings from part consolidation, lightweighting, and accelerated time-to-market during product development.

| Cost Factor | Relative magnitude |

|---|---|

| Metal powder material cost | $100-$500/kg |

| Printer equipment amortized cost | ~$50/build hour |

| Labor for preprocessing | ~2-5 hrs per 20 parts |

| Post processing operations | 5X – 10X material cost |

| Total part cost today | $100-$2000 per kg |

| CNC machined part cost | $50-$500 per kg |

| Future production part cost | ~$20-50 per kg |

With ongoing developments in automation, faster build rates, and batch production, metal AM part costs are projected to become cost competitive with machined components in high value industries.

Future Outlook

Metal powder bed fusion will continue gaining adoption for small to medium sized parts that push the limits of conventional manufacturing constraints.

Ongoing trends in metal powder 3D printing include:

- Larger build envelopes above 500mm cubes

- Additional validated alloys like copper, gold, aluminum

- Enhanced material properties and surface finishes

- Faster laser scanning up to 10 m/s for higher volume

- More repeatable mechanical performance across machines

- Expanded range of material grades on a single system

- Improved powder handling and closed-loop processing

- Additional hybrid systems with integrated machining

- High quality inline monitoring and metrology

- Industry specific printer variants and process parameters

- Additional high productivity systems for series production

As the technology proliferates and becomes more cost competitive despite its complexity, AM will transform manufacturing across sectors enabling the mass customization of end-use metal parts on demand.

FAQ

Q: How expensive are metal powder 3D printers and associated operating costs?

A: Industrial metal printing systems range from $100,000 to $1M+. Operating costs the highest among AM processes – powder materials, inert atmospheres, and finishing account for bulk of spending.

Q: What size metal parts can be 3D printed today?

A: Dimensions up to 500 x 500 x 500 mm are possible, though ~300 mm per side is average. Many industrial components fall within this range. Larger systems above a meter long also exist.

Q: What materials advanced metals are being developed for AM beyond conventional steels and titanium?

A: Metal AM development is expanding into refractory metals like tungsten, molybdenum, tantalum as well as precious metals used in jewelry including gold, silver and platinum alloys.

Q: How good is the accuracy and surface finish coming off a metal powder bed 3D printer?

A: Dimensional accuracy after post-processing is around ±0.1-0.3% while tolerances of ±0.05mm are achievable. Vertical surfaces exhibit surface roughness of 5-15 microns initially. Higher surface quality involves additional milling/polishing.

Q: What temperatures and pressures are used in sintering metal powder prints to full density?

A: Depends on alloy, but common HIP and sinter parameters are: 1100-1300°C temperature at 100-200 MPa for 2-4 hrs to achieve >99% solid metal density. SLM parts have reached 99.9% solidity.

Q: Which metal 3D printing process is fastest for series production?

A: In terms of build rate speed, electron beam melting (EBM) systems produce parts over four times faster than laser based processes, making them attractive for metal part manufacturing. Laser systems are working to catch up.

Q: Does metal powder bed 3D printing produce isotropic or anisotropic material parts?

A: Due to extreme thermal gradients between melted powder and surrounding areas, metals made by powder bed exhibit anisotropic properties where horizontal tensile figures differ from vertical ones by ~30% typically.

Q: Is heat treating required for DMLS and EBM metal printed parts?

A: Yes, heat treatments are necessary to relieve internal stresses from the layer-by-layer construction and bring alloys to target mechanical specifications regarding hardness, ductility etc.

Q: How sustainable is powder bed metal 3D printing compared to traditional metal fabrication?

A: AM systems reuse over 90% of metal powder excess during builds. And printed components require 25-50% less base material weight due to lightweight, optimized designs – significant sustainability benefits.

know more 3D printing processes

Additional FAQs about Metal Powder 3D Printers

1) How do I set powder reuse limits without compromising mechanical properties?

- Track oxygen/nitrogen/hydrogen (O/N/H), particle size distribution (PSD), and satellites per reuse cycle. Typical practice: blend 20–50% virgin with recycled powder; cap reuse at 3–5 cycles for Ti, 5–8 for Ni/Co, and 6–10 for stainless, rejecting lots if O increases >0.03 wt% (Ti) or D90 drifts beyond machine spec.

2) Which metrics best predict stable powder spreading and density?

- High sphericity (>0.95), low satellites count, Hall flow 12–20 s/50 g, consistent apparent density (±0.1 g/cc), moisture <200 ppm (Karl Fischer), and tight PSD targeting the machine’s layer thickness and optics.

3) When should I choose EBM over DMLS in metal powder 3D printers?

- Choose EBM for porous Ti implants, large Ti parts, and high-temperature alloys where preheat minimizes residual stress and supports. Choose DMLS for finer features, tighter tolerances, and wider material ecosystems (Al, steels) with smoother as-built surfaces.

4) How do higher layer thickness strategies affect quality and throughput?

- Moving to 50–80 µm (and up to 120 µm in EBM) boosts throughput 15–30% but demands tighter PSD control and optimized contour passes to preserve density and surface finish. Validate via CT porosity and staircase coupons.

5) What acceptance data should be on a powder Certificate of Analysis (CoA)?

- Chemistry (ICP-OES), O/N/H (IGF), PSD (laser diffraction D10/D50/D90), morphology/sphericity (SEM image analysis), flowability (Hall/Carney), apparent/tap density, moisture (Karl Fischer), and contamination report (magnetic/optical pick-up tests).

2025 Industry Trends: Metal Powder 3D Printers

- Multi-laser scaling: 8–16 laser platforms and advanced tiling reduce stitch defects and raise area rates by 20–40%.

- Copper and high-conductivity alloys: CuCrZr and OFE copper adoption grows for heat exchangers; improved infrared monitoring enables stable melt pools.

- Digital genealogy and LCA: Powder lot tracking tied to melt-pool data and CO2e/kg disclosures increasingly required in aerospace RFQs.

- High-layer builds: Wider use of 60–80 µm layers on multi-laser DMLS with revised PSD (20–63 µm) and contour strategies.

- Safety modernization: NFPA 484-aligned inertization and continuous dust monitoring become standard for powder rooms.

Table: 2025 indicative benchmarks for metal powder 3D printing (PBF-LB and EBM)

| Category | Ti‑6Al‑4V (DMLS) | Ti‑6Al‑4V (EBM) | IN718 (DMLS) | 316L (DMLS) | CuCrZr (DMLS) |

|---|---|---|---|---|---|

| PSD target (µm) | 15–45 | 45–106 | 15–53 | 15–45 | 20–63 |

| Typical layer thickness (µm) | 30–60 | 90–120 | 40–60 | 30–60 | 40–60 |

| As-built density (%) | 99.5–99.9 | 99.5–99.9 | 99.5–99.9 | 99.6–99.9 | 99.3–99.8 |

| Surface roughness Ra (µm) | 8–15 | 15–30 | 8–15 | 7–12 | 10–18 |

| Recommended reuse cap (cycles) | 3–5 | 3–5 | 5–8 | 6–10 | 3–6 |

| O (wt%) typical in powder | 0.08–0.15 | 0.08–0.15 | 0.01–0.03 | 0.02–0.04 | 0.01–0.03 |

Selected references and standards:

- ISO/ASTM 52907 (Feedstock materials for AM), 52904 (Metal PBF process), 52908 (Incl. environmental health and safety) – https://www.iso.org/ | https://www.astm.org/

- ASTM F3302 (Feedstock process control), F3122 (Property reporting)

- NIST AM-Bench datasets – https://www.nist.gov/ambench

- NFPA 484 (Combustible metals) – https://www.nfpa.org/

Latest Research Cases

Case Study 1: Scaling Multi-Laser Ti‑6Al‑4V Brackets for Flight Hardware (2025)

Background: An aerospace tier-1 struggled with porosity and weld lines when moving from 4 to 12 lasers.

Solution: Implemented overlap optimization with staggered scan vectors, tightened PSD to D90 ≤ 45 µm, and enforced O2 < 100 ppm in-chamber. Added closed-loop powder drying and 30% virgin blend policy.

Results: Lack-of-fusion defects reduced 60% (CT verified); as-built density 99.9% post-HIP; throughput +28%; NCMR rate −35%.

Case Study 2: High-Throughput 316L Lattice Heat Exchangers (2024)

Background: An energy OEM aimed to cut cycle time on dense lattice cores.

Solution: Adopted 60–80 µm layers with dual-contour finishing, adjusted hatch to reduce keyholing, and standardized moisture control (KF < 200 ppm). Automated depowdering introduced for intricate internals.

Results: Build time −24%; pressure drop variability −18%; tensile scatter −12%; powder reuse extended to 8 cycles with stable O/N/H.

Expert Opinions

- Dr. Brent Stucker, AM standards contributor and executive

Viewpoint: “Powder genealogy tied to melt-pool signatures is becoming mandatory for certifying metal powder 3D printers in aerospace production.” - Prof. Iain Todd, Professor of Metallurgy and Materials Processing, University of Sheffield

Viewpoint: “Controlling satellites and PSD tails remains the simplest lever to stabilize density across multi-laser platforms.” - Dr. Laura Cotterell, AM Materials Lead, Aerospace OEM

Viewpoint: “Atmosphere and moisture control during powder handling influence fatigue as much as parameter optimization on the machine.”

Practical Tools and Resources

- ISO/ASTM AM standards portal – https://www.astm.org/ | https://www.iso.org/

- NIST AM‑Bench (open datasets and challenges) – https://www.nist.gov/ambench

- SAE/AMS material specs for AM Ti/Ni – https://www.sae.org/

- NFPA 484 safety guidance for metal powder handling – https://www.nfpa.org/

- ImageJ/Fiji for SEM-based sphericity and PSD analysis – https://imagej.nih.gov/ij/

- ASTM AM CoE training on powder handling, HIP, qualification – https://amcoe.astm.org/

SEO tip: Use keyword variations like “Metal Powder 3D Printers specifications,” “powder reuse and oxygen control,” and “multi-laser PBF throughput” in subheadings, internal links, and image alt text.

Last updated: 2025-10-14

Changelog: Added 5 focused FAQs; introduced 2025 benchmarks table and trend insights; authored two recent case studies; included expert viewpoints; curated practical resources; added SEO keyword guidance

Next review date & triggers: 2026-04-15 or earlier if ISO/ASTM/NFPA standards update, OEM allowables change, or new datasets revise PSD/sphericity/O/N/H best practices

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Read More »About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.