The main classification of 3D printed metal powders

Table of Contents

Imagine a world where complex metal objects materialize from a bed of dust, layer by layer. This isn’t science fiction; it’s the reality of 3D printed metal powders. But what exactly are these powders, and how do they transform into the building blocks of groundbreaking innovations? Buckle up, because we’re about to embark on a journey into the fascinating world of 3D printed metal powders.

Iron Based Powders

Iron-based powders, like stainless steel, are the workhorses of the 3D printing industry. Think of them as the reliable pickup trucks of the metal powder world. They’re affordable, versatile, and offer a good balance of strength, corrosion resistance, and weldability. This makes them ideal for a wide range of applications, from automotive parts and medical implants to architectural components and household appliances.

However, iron-based powders can be a bit heavier compared to some other options, and their surface finish might not be as smooth. But hey, you can’t have it all, right? For those applications where weight is a major concern, other metal powders might be a better fit.

Examples of Iron Based Powders:

- Stainless Steel (316L, 17-4PH)

- Low-alloy Steel

Aluminum Based Powders

Aluminum-based powders are the lightweight champions of the 3D printing arena. Imagine a sleek sports car compared to the trusty pickup truck. These powders offer excellent strength-to-weight ratios, making them ideal for applications where weight is a critical factor, such as aerospace components and automotive parts. They’re also highly conductive for heat and electricity, opening doors for applications in electronics and heat sinks.

However, aluminum-based powders can be a bit more challenging to print with compared to iron-based powders. They’re also susceptible to corrosion in certain environments. So, while they excel in weight reduction, they might require additional considerations for specific applications.

Examples of Aluminum Based Powders:

- Aluminum Alloys (AlSi10Mg, AlSi7Mg0.3)

Titanium Based Powders

Titanium-based powders are the high-performance titans of the metal powder world. Think of them as the fighter jets of the group. They offer an incredible combination of strength, low weight, and excellent corrosion resistance. This makes them perfect for demanding applications in the aerospace, medical, and oil & gas industries. Titanium implants, for example, are highly biocompatible and can last a lifetime in the human body.

However, titanium-based powders are among the most expensive options, and they can be tricky to print with due to their high melting point. So, while their performance is unmatched, they come at a premium cost and require specialized expertise for printing.

Examples of Titanium Based Powders:

- Titanium Alloys (Ti6Al4V, CP Titanium)

Nickel Based Powders

Nickel-based powders are the heat resistant powerhouses of the metal powder world. Imagine them as the fireproof suits that allow firefighters to walk into infernos. These powders excel in high-temperature environments, making them ideal for applications like jet engines, turbines, and heat exchangers. They also offer good corrosion resistance and strength.

However, nickel-based powders can be quite expensive and might present some health concerns during the printing process due to the presence of nickel. So, while they can withstand scorching temperatures, proper safety protocols are essential when working with them.

Examples of Nickel Based Powders:

- Inconel 625

- Hastelloy X

Cobalt Based Powders

Cobalt-based powders are the biocompatible all-stars of the metal powder world. Think of them as the friendly robots that assist surgeons in delicate operations. These powders offer excellent biocompatibility, making them perfect for medical implants like hip replacements and dental crowns. They also boast good corrosion resistance and strength.

However, cobalt-based powders can be expensive and might have similar health concerns as nickel-based powders during printing. Additionally, cobalt can be brittle in some forms, so careful selection of the specific powder is crucial.

Examples of Cobalt Based Powders:

- CoCrMo

- Cobalt Chrome (CoCr)

Choosing the Right Metal Powder

With so many options, selecting the right metal powder for your 3D printing project can feel like playing matchmaker. You need to find the perfect match between the material properties and the specific requirements of your application. Here are some key factors to consider:

- Strength and Weight: Do you need a material that’s incredibly strong for structural components, or is lightweight a priority for applications like aerospace parts? Iron-based powders offer a good balance, while aluminum shines in weight reduction. Titanium takes the crown for high-strength, lightweight applications, but at a cost.

- Corrosion Resistance: Will your printed part be exposed to harsh environments or chemicals? Stainless steel excels in corrosion resistance, while aluminum might need additional treatments depending on the environment. Titanium offers excellent natural resistance in many applications.

- Biocompatibility: Is the part going to be implanted in the human body? Cobalt-based powders are biocompatible superstars, making them ideal for medical implants. Titanium also boasts good biocompatibility for specific applications.

- Printability: How easy is the powder to work with during the 3D printing process? Iron-based powders are generally considered more printer-friendly compared to titanium or aluminum. Printing parameters and expertise can play a big role here.

- Cost: Let’s be honest, budget matters. Iron-based powders are typically the most affordable option, while titanium and nickel-based powders come at a premium.

Here’s a handy comparison table to summarize the key characteristics of different metal powders:

| Property | Iron Based | Aluminum Based | Titanium Based | Nickel Based | Cobalt Based |

|---|---|---|---|---|---|

| Strength | Good | Good | Excellent | Excellent | Good |

| Weight | Heavy | Light | Light | Moderate | Moderate |

| Corrosion Resistance | Excellent | Moderate | Excellent | Excellent | Good |

| Biocompatibility | No | No | Good | No | Excellent |

| Printability | Easy | Moderate | Difficult | Difficult | Moderate |

| Cost | Low | Moderate | High | High | High |

Remember, this table is a general guide, and specific powder variations within each category can have different properties. It’s always best to consult with a 3D printing expert to determine the most suitable metal powder for your unique project needs.

Advanced Considerations for 3D printed metal powders

Now that you have a grasp on the main types of metal powders, let’s delve a little deeper. Here are some additional factors to consider when choosing a metal powder:

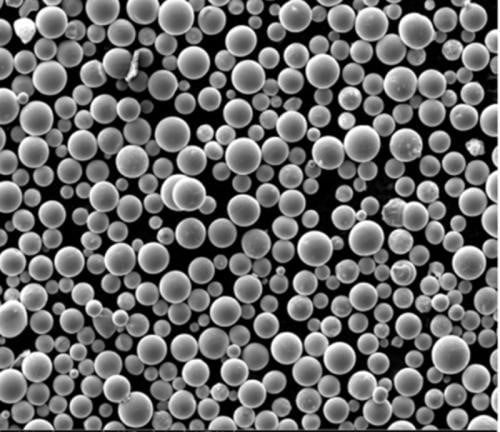

- Particle Size and Distribution: The size and distribution of the metal powder particles significantly impact the printability, surface finish, and mechanical properties of the final part. Finer particles generally lead to smoother finishes but might be trickier to print.

- Powder Flowability: How easily does the powder flow? Good flowability ensures consistent layer formation during the printing process, leading to better part quality.

- Sphericity: The shape of the powder particles also plays a role. Spherical particles tend to flow better and pack more densely, leading to stronger parts.

- Powder Purity: The presence of impurities in the powder can affect the printability and final properties of the part. Using high-purity powders ensures optimal results.

- Recyclability: With sustainability becoming a growing concern, the ability to recycle used metal powder is a valuable consideration. Some metal powders can be recycled to a certain extent, reducing waste and cost.

Future of Metal Powders

The world of 3D printed metal powder is constantly evolving. Researchers are developing new and innovative powders with improved properties. Here are some exciting trends to watch out for:

- Multi-material powders: Imagine printing a part with different materials in specific regions. Multi-material powders are being developed to achieve this, enabling parts with varying functionalities within a single print.

- Nanopowders: Powders with extremely small particle sizes (nanoparticles) are being explored. These nanopowders offer the potential for even higher strength, improved surface finishes, and the creation of new material properties.

- Sustainable Powders: The development of powders made from recycled materials or with lower environmental impact is a growing focus. This aligns with the push for more sustainable manufacturing practices.

FAQ

Q: What are the main types of metal powders used in 3D printing?

A: The main types of metal powders used in 3D printing include:

- Iron-based powders: Affordable, versatile, and offer a good balance of strength, corrosion resistance, and weldability. Examples include stainless steel and low-alloy steel.

- Aluminum-based powders: Lightweight champions with excellent strength-to-weight ratio, ideal for aerospace and automotive parts. Examples include Aluminum Alloys (AlSi10Mg, AlSi7Mg0.3).

- Titanium-based powders: High-performance titans offering exceptional strength, low weight, and excellent corrosion resistance. Used in demanding applications like aerospace, medical, and oil & gas industries. Examples include Titanium Alloys (Ti6Al4V, CP Titanium).

- Nickel-based powders: Heat resistant powerhouses that excel in high-temperature environments like jet engines and turbines. Examples include Inconel 625 and Hastelloy X.

- Cobalt-based powders: Biocompatible all-stars, perfect for medical implants due to their excellent biocompatibility and corrosion resistance. Examples include CoCrMo and Cobalt Chrome (CoCr).

Q: How do I choose the right metal powder for my 3D printing project?

A: Choosing the right metal powder involves considering several factors:

- Strength and Weight: Do you need high strength or lightweight properties? Iron offers a good balance, aluminum excels in weight reduction, while titanium is a leader in high-strength, lightweight applications.

- Corrosion Resistance: Will the part be exposed to harsh environments? Stainless steel offers excellent resistance, while aluminum might require additional treatments depending on the situation.

- Biocompatibility: Is the part for medical implants? Cobalt-based powders are ideal for biocompatibility.

- Printability: How easy is the powder to work with? Iron-based powders are generally easier to print compared to titanium or aluminum.

- Cost: Iron-based powders are typically the most affordable, while titanium and nickel-based options come at a premium.

Q: What are some additional factors to consider when choosing a metal powder?

A: Beyond the basics, consider:

- Particle Size and Distribution: Impacts printability, surface finish, and mechanical properties. Finer particles might be trickier to print but offer smoother finishes.

- Powder Flowability: Good flow ensures consistent layer formation during printing, leading to better part quality.

- Sphericity: The shape of particles affects flow and packing density. Spherical particles tend to flow better and create stronger parts.

- Powder Purity: Impurities can affect printability and final properties. Use high-purity powders for optimal results.

- Recyclability: With sustainability in mind, consider the ability to recycle used powder to reduce waste and cost.

Q: What are some future trends in metal powders for 3D printing?

A: The future is exciting:

- Multi-material powders: Imagine printing a part with different materials in specific regions. This enables parts with varying functionalities within a single print.

- Nanopowders: Powders with extremely small particles offer the potential for even higher strength, improved finishes, and creation of new material properties.

- Sustainable Powders: Development of powders made from recycled materials or with lower environmental impact aligns with the push for sustainable manufacturing.

Conclusion

Metal powders for 3D printing are the building blocks of a revolution. From the workhorse reliability of iron-based powders to the cutting-edge performance of titanium and nickel alloys, each option unlocks a unique set of possibilities. As technology continues to evolve, the future of metal powders is bright, promising even more innovative materials and applications. So, the next time you see a complex metal object, remember the magic that happens behind the scenes – the dance of metal powders transforming into groundbreaking realities.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Read More »About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.