Binder Jet 3D Printing

Table of Contents

Welcome to the fascinating world of binder jet 3D printing! If you’re curious about this cutting-edge technology, you’re in the right place. In this guide, we’ll dive deep into every aspect of binder jet 3D printing, from the basics to the intricate details, complete with tables, comparisons, and FAQs. Ready to explore? Let’s get started!

Overview of Binder Jet 3D Printing

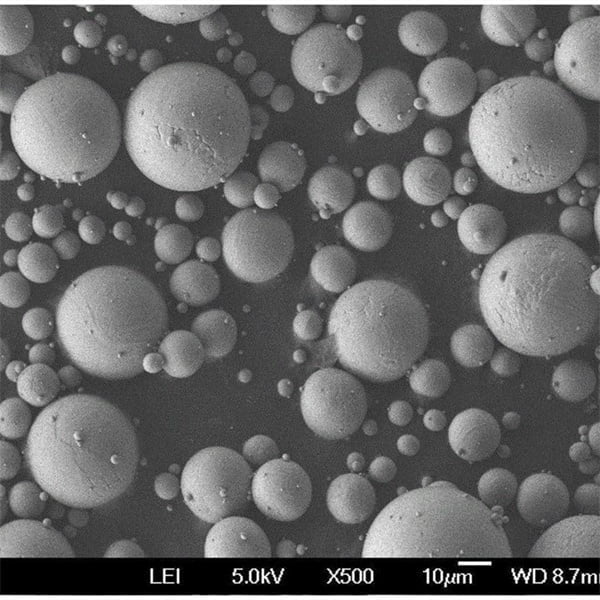

Binder jet 3D printing is a revolutionary additive manufacturing process. Unlike traditional methods, it uses a binding agent to adhere powder particles together, layer by layer, to create complex and precise parts. This technique is gaining popularity across various industries due to its versatility and efficiency.

Key Highlights:

- Process: Utilizes a binding agent to fuse powder materials.

- Materials: Compatible with metals, ceramics, and composites.

- Applications: Automotive, aerospace, medical, and more.

- Advantages: Cost-effective, scalable, and capable of producing intricate designs.

Types of Metal Powders for Binder Jet 3D Printing

Choosing the right metal powder is crucial for achieving optimal results in binder jet 3D printing. Here, we’ll discuss some specific models and their unique properties.

| Metal Powder Model | Description |

|---|---|

| 316L Stainless Steel | Known for its excellent corrosion resistance and mechanical properties. Ideal for medical devices. |

| Inconel 625 | A nickel-based superalloy with high strength and resistance to extreme environments. |

| Copper | Offers excellent thermal and electrical conductivity, making it suitable for electronics. |

| Aluminum AlSi10Mg | Lightweight with good mechanical properties, commonly used in aerospace and automotive. |

| Titanium Ti6Al4V | High strength-to-weight ratio and biocompatibility, perfect for aerospace and medical implants. |

| Tool Steel H13 | Provides high hardness and resistance to wear and heat, ideal for tooling applications. |

| Nickel Alloy 718 | High strength and oxidation resistance, used in high-temperature applications. |

| Cobalt-Chrome | Excellent wear and corrosion resistance, often used in dental and orthopedic implants. |

| 316 Stainless Steel | Offers a balance of strength, corrosion resistance, and cost-effectiveness. |

| Bronze | Known for its durability and thermal conductivity, used in decorative and industrial parts. |

Composition and Properties of Metal Powders

Understanding the composition and properties of these metal powders is essential for selecting the right material for your specific application. Let’s break down the key characteristics.

| Metal Powder Model | Composition | Properties |

|---|---|---|

| 316L Stainless Steel | Fe, Cr, Ni, Mo | High corrosion resistance, good mechanical properties, non-magnetic. |

| Inconel 625 | Ni, Cr, Mo, Nb | High strength, excellent oxidation and corrosion resistance, good weldability. |

| Copper | Cu | Excellent thermal and electrical conductivity, ductile, corrosion-resistant. |

| Aluminum AlSi10Mg | Al, Si, Mg | Lightweight, high strength-to-weight ratio, good casting properties. |

| Titanium Ti6Al4V | Ti, Al, V | High strength, low density, excellent biocompatibility, corrosion-resistant. |

| Tool Steel H13 | Fe, Cr, Mo, V, Si | High hardness, heat resistance, wear resistance, good toughness. |

| Nickel Alloy 718 | Ni, Cr, Fe, Mo, Nb | High strength, excellent oxidation and corrosion resistance, good fatigue resistance. |

| Cobalt-Chrome | Co, Cr, Mo | High wear resistance, excellent corrosion resistance, biocompatible. |

| 316 Stainless Steel | Fe, Cr, Ni | Balance of strength and corrosion resistance, cost-effective. |

| Bronze | Cu, Sn | Durable, good thermal conductivity, corrosion-resistant, aesthetically pleasing. |

Applications of Binder Jet 3D Printing

Binder jet 3D printing is making waves in various industries. Here are some notable applications where this technology shines.

| Industry | Application | Metal Powder Model |

|---|---|---|

| Automotive | Lightweight structural components, engine parts | Aluminum AlSi10Mg, Inconel 625 |

| Aerospace | Turbine blades, structural components, satellite parts | Titanium Ti6Al4V, Nickel Alloy 718 |

| Medical | Dental implants, orthopedic implants, surgical instruments | Cobalt-Chrome, 316L Stainless Steel |

| Electronics | Heat sinks, electrical connectors, circuit boards | Copper, Aluminum AlSi10Mg |

| Tooling | Molds, dies, cutting tools | Tool Steel H13, Inconel 625 |

| Energy | Turbine components, heat exchangers | Nickel Alloy 718, Inconel 625 |

| Consumer Goods | Jewelry, decorative items, customized products | Bronze, Copper |

| Defense | Lightweight armor, weapon components | Titanium Ti6Al4V, Inconel 625 |

| Construction | Architectural models, custom metal parts | Bronze, 316L Stainless Steel |

| Research | Prototyping, material testing, custom experimental setups | Various based on research needs |

Specifications, Sizes, Grades, and Standards

When it comes to binder jet 3D printing, adhering to specific standards and choosing the right sizes and grades is critical. Here’s a breakdown of these specifications for different metal powders.

| Metal Powder Model | Specifications | Sizes | Grades | Standards |

|---|---|---|---|---|

| 316L Stainless Steel | ASTM A276, ASTM A240 | 15-45 µm | 316L | ISO 5832-1, UNS S31603 |

| Inconel 625 | ASTM B443, AMS 5599 | 15-53 µm | 625 | AMS 5666, UNS N06625 |

| Copper | ASTM B152, ASTM B187 | 20-45 µm | ETP, OFHC | UNS C11000, UNS C10100 |

| Aluminum AlSi10Mg | ISO 3522, ASTM B918 | 20-63 µm | AlSi10Mg | DIN EN 1706, UNS A03600 |

| Titanium Ti6Al4V | ASTM B348, ASTM F1472 | 15-45 µm | Ti6Al4V | AMS 4911, UNS R56400 |

| Tool Steel H13 | ASTM A681, SAE J438 | 15-53 µm | H13 | UNS T20813, ISO 4957 |

| Nickel Alloy 718 | ASTM B637, AMS 5662 | 15-53 µm | 718 | UNS N07718, ISO 15156-3 |

| Cobalt-Chrome | ASTM F1537, ASTM F75 | 15-45 µm | CoCrMo | ISO 5832-12, UNS R31538 |

| 316 Stainless Steel | ASTM A276, ASTM A240 | 15-45 µm | 316 | ISO 5832-1, UNS S31600 |

| Bronze | ASTM B427, ASTM B505 | 20-45 µm | Various | UNS C90700, UNS C90500 |

Suppliers and Pricing Details

Selecting the right supplier and understanding pricing details are essential for budgeting and planning. Here are some reputable suppliers along with estimated pricing.

| Supplier | Metal Powder Model | Pricing (per kg) | Contact Information |

|---|---|---|---|

| Höganäs | 316L Stainless Steel | $80 – $120 | www.hoganas.com |

| Carpenter Technology | Inconel 625 | $100 – $150 | www.cartech.com |

| GKN Additive | Copper | $50 – $70 | www.gknpm.com |

| Sandvik | Aluminum AlSi10Mg | $60 – $90 | www.materials.sandvik |

| Arcam AB | Titanium Ti6Al4V | $200 – $300 | www.arcam.com |

| Aubert & Duval | Tool Steel H13 | $70 – $110 | www.aubertduval.com |

| ATI Specialty Materials | Nickel Alloy 718 | $150 – $200 | www.atimetals.com |

| EOS GmbH | Cobalt-Chrome | $200 – $250 | www.eos.info |

| LPW Technology | 316 Stainless Steel | $80 – $120 | www.lpwtechnology.com |

| Metal Powder Works | Bronze | $40 – $60 | www.metalpowderworks.com |

Pros and Cons of Binder Jet 3D Printing

Understanding the advantages and limitations of binder jet 3D printing can help you make informed decisions. Let’s break it down.

Advantages of Binder Jet 3D Printing

| Advantage | Description |

|---|---|

| Cost-Effective | Lower material and production costs compared to other 3D printing methods. |

| Scalability | Suitable for both small-scale and large-scale production runs. |

| Design Flexibility | Capable of producing complex geometries and intricate designs. |

| Material Variety | Compatible with a wide range of materials, including metals, ceramics, and composites. |

| No Thermal Distortion | No thermal stresses or distortions, as the process occurs at room temperature. |

Disadvantages of Binder Jet 3D Printing

| Disadvantage | Description |

|---|---|

| Post-Processing Required | Requires additional steps such as curing, sintering, or infiltrating. |

| Lower Strength | Parts may have lower mechanical strength compared to other 3D printing methods. |

| Powder Management | Handling and recycling powder can be challenging and requires proper equipment. |

| Surface Finish | May require additional finishing to achieve smooth surfaces. |

| Porosity | Parts can be porous, affecting their structural integrity and performance. |

FAQ

| Question | Answer |

|---|---|

| What is binder jet 3D printing? | Binder jet 3D printing is an additive manufacturing process that uses a binding agent to fuse powder particles. |

| What materials can be used in binder jet 3D printing? | A variety of materials including metals, ceramics, and composites can be used. |

| What are the advantages of binder jet 3D printing? | Cost-effective, scalable, design flexibility, material variety, and no thermal distortion. |

| What are the disadvantages of binder jet 3D printing? | Requires post-processing, lower strength, powder management, surface finish, and porosity issues. |

| Which industries benefit from binder jet 3D printing? | Automotive, aerospace, medical, electronics, tooling, energy, consumer goods, defense, construction, and research. |

| How does binder jet 3D printing compare to other 3D printing methods? | It is generally more cost-effective and versatile but may require more post-processing and have lower part strength. |

| Can binder jet 3D printing produce complex designs? | Yes, it excels in producing complex geometries and intricate designs. |

| What is the cost of metal powders for binder jet 3D printing? | The cost varies by material, ranging from $40 to $300 per kilogram. |

| What post-processing steps are required for binder jet 3D printing? | Common steps include curing, sintering, and infiltrating to enhance part strength and finish. |

| Is binder jet 3D printing suitable for mass production? | Yes, it is scalable and can be used for both small-scale and large-scale production runs. |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731