Blog

all colletions

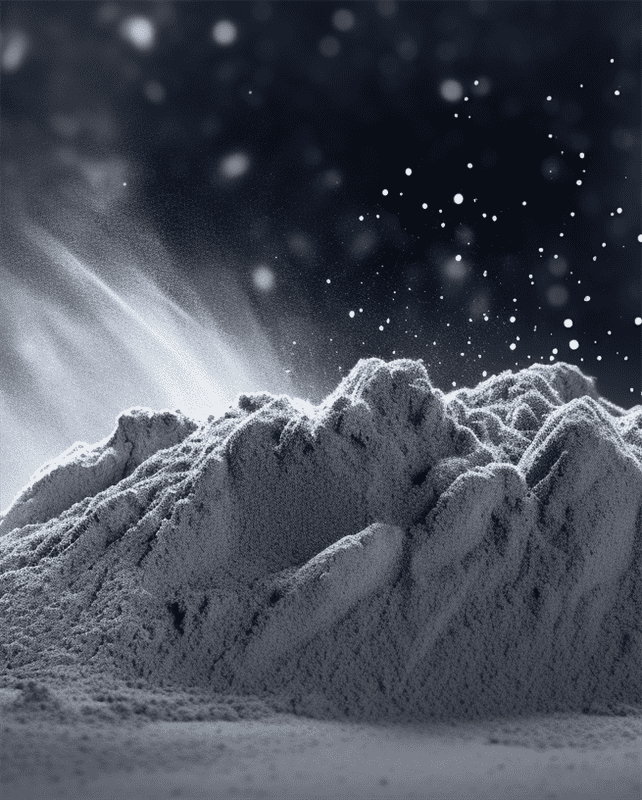

Titanium Alloy Powders: Composition, Manufacturing and Applications

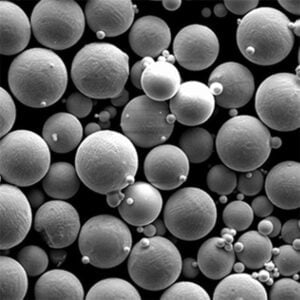

Titanium alloy powders contain titanium as the main element combined with other metals like aluminum, vanadium or iron. The alloy composition imparts enhanced properties for uses across aerospace, medical devices and more. Types of Titanium Alloy Powders Common titanium alloy formulations in powder form: Alloy Ti Content Other Elements Key

MIM Metal Powder

Metal injection molding, or MIM metal powder, is a manufacturing process gaining popularity for its ability to produce complex, high-precision metal parts in high volumes. At its core, the MIM process utilizes a feedstock consisting of fine metal powder particles mixed with a binder material. When injected into a mold,

Metal Alloy Powders

Metal alloy powders refer to particulate blends of two or more metal elements used across manufacturing, additive techniques and research applications. This guide serves as an in-depth reference on metal alloy powders – exploring types, production methods, key properties, specifications, suppliers, pricing, applications, comparisons and more. Overview of Metal Alloy

Titanium Aluminide Powder

Titanium aluminide refers to a class of lightweight, high strength intermetallic alloys composed of titanium and aluminum. This guide serves as a reference on titanium aluminide in powder format – exploring manufacturing methods, compositions, key traits and parameters, suppliers and pricing, diverse end-use applications across industries, FAQs and more. Overview

3D Printing Powders

3D printing, also known as additive manufacturing (AM), utilizes specialized powders to construct three-dimensional components in successive layering methods. This guide serves an in-depth reference on powders for 3D printing – exploring types, traits, specifications, manufacturing methods, key suppliers & pricing, applications across industries, comparisons to alternatives, FAQs and more.

HIP Technology

HIP technology or Hot Isostatic Pressing is an advanced manufacturing process to eliminate porosity, increase density, and improve mechanical properties of parts produced via additive manufacturing, casting, powder metallurgy and other techniques. HIP technology Process Table 1: Summary of The Hot Isostatic Pressing Process Parameters Details Principle High temperature +

Titanium Alloy Powders: Composition, Manufacturing and Applications

Titanium alloy powders contain titanium as the main element combined with other metals like aluminum, vanadium or iron. The alloy composition imparts enhanced properties for

MIM Metal Powder

Metal injection molding, or MIM metal powder, is a manufacturing process gaining popularity for its ability to produce complex, high-precision metal parts in high volumes.

Metal Alloy Powders

Metal alloy powders refer to particulate blends of two or more metal elements used across manufacturing, additive techniques and research applications. This guide serves as

Titanium Aluminide Powder

Titanium aluminide refers to a class of lightweight, high strength intermetallic alloys composed of titanium and aluminum. This guide serves as a reference on titanium

3D Printing Powders

3D printing, also known as additive manufacturing (AM), utilizes specialized powders to construct three-dimensional components in successive layering methods. This guide serves an in-depth reference

HIP Technology

HIP technology or Hot Isostatic Pressing is an advanced manufacturing process to eliminate porosity, increase density, and improve mechanical properties of parts produced via additive

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731