Blog

all colletions

The Best Aerospace Additive Manufacturing in Hamburg: A Comprehensive Guide for B2B Buyers

1. Introduction to Aerospace Additive Manufacturing in Hamburg Hamburg is a key hub for aerospace manufacturing in Europe, home to leading companies such as Airbus and Lufthansa Technik. With the growing demand for lightweight, high-performance parts, additive manufacturing (AM) in aerospace has gained significant traction in the region. Aerospace additive

Aerospace-Grade Metal 3D Printing in Abu Dhabi: A Comprehensive Guide for B2B Buyers

1. Introduction to Aerospace-Grade Metal 3D Printing The aerospace industry demands precision, lightweight materials, and high-performance components. Traditional manufacturing methods often struggle with complex geometries and material efficiency. This is where metal 3D printing revolutionizes aerospace manufacturing, providing high-strength, lightweight, and cost-efficient parts. Why Metal 3D Printing is Critical for

High-Performance Metal Parts in Busan: A Comprehensive Guide for Wholesale Buyers and Distributors

1. Introduction to High-Performance Metal Parts in Busan Busan, South Korea, is a major hub for industrial manufacturing, particularly in the production of high-performance metal parts. The city boasts a strong supply chain, advanced manufacturing technologies, and a skilled workforce, making it an attractive destination for wholesale buyers, distributors, and

Metal Fabrication with Additive Manufacturing: A Guide for B2B Buyers and Suppliers

1. Introduction to Metal Fabrication with Additive Manufacturing Metal fabrication has traditionally relied on subtractive manufacturing methods such as CNC machining and casting. However, with the rise of additive manufacturing (AM), businesses are now leveraging metal 3D printing to create complex, lightweight, and durable components with unprecedented design freedom. What

Stainless Steel Additive Manufacturing in Lyon: A Complete Guide for B2B Buyers

1. Introduction: The Rise of Stainless Steel Additive Manufacturing in Lyon Lyon, one of France’s leading industrial hubs, has become a key center for stainless steel additive manufacturing. With a strong presence in aerospace, medical, and automotive industries, the city is leveraging 3D printing technology to enhance manufacturing efficiency, reduce

High-Strength Steel 3D Printing in Munich: A Complete Guide for B2B Buyers

1. Introduction to High-Strength Steel 3D Printing What is High-Strength Steel 3D Printing? High-strength steel 3D printing is a cutting-edge manufacturing technology that enables businesses to create complex, durable, and lightweight steel components with superior mechanical properties. Using advanced additive manufacturing (AM) techniques like Selective Laser Melting (SLM) and Electron

The Best Aerospace Additive Manufacturing in Hamburg: A Comprehensive Guide for B2B Buyers

1. Introduction to Aerospace Additive Manufacturing in Hamburg Hamburg is a key hub for aerospace manufacturing in Europe, home to leading companies such as Airbus

Aerospace-Grade Metal 3D Printing in Abu Dhabi: A Comprehensive Guide for B2B Buyers

1. Introduction to Aerospace-Grade Metal 3D Printing The aerospace industry demands precision, lightweight materials, and high-performance components. Traditional manufacturing methods often struggle with complex geometries

High-Performance Metal Parts in Busan: A Comprehensive Guide for Wholesale Buyers and Distributors

1. Introduction to High-Performance Metal Parts in Busan Busan, South Korea, is a major hub for industrial manufacturing, particularly in the production of high-performance metal

Metal Fabrication with Additive Manufacturing: A Guide for B2B Buyers and Suppliers

1. Introduction to Metal Fabrication with Additive Manufacturing Metal fabrication has traditionally relied on subtractive manufacturing methods such as CNC machining and casting. However, with

Stainless Steel Additive Manufacturing in Lyon: A Complete Guide for B2B Buyers

1. Introduction: The Rise of Stainless Steel Additive Manufacturing in Lyon Lyon, one of France’s leading industrial hubs, has become a key center for stainless

High-Strength Steel 3D Printing in Munich: A Complete Guide for B2B Buyers

1. Introduction to High-Strength Steel 3D Printing What is High-Strength Steel 3D Printing? High-strength steel 3D printing is a cutting-edge manufacturing technology that enables businesses

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

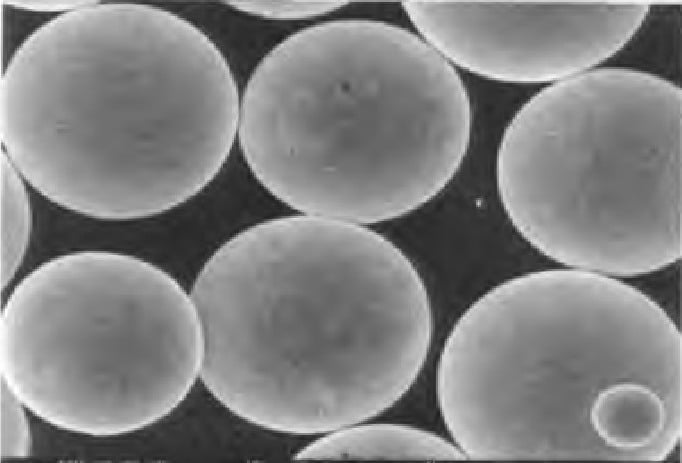

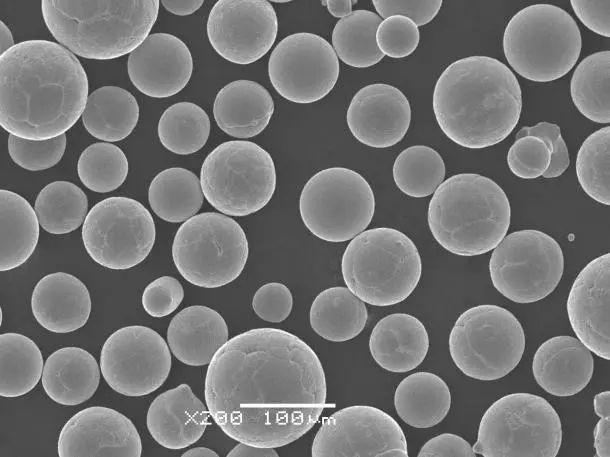

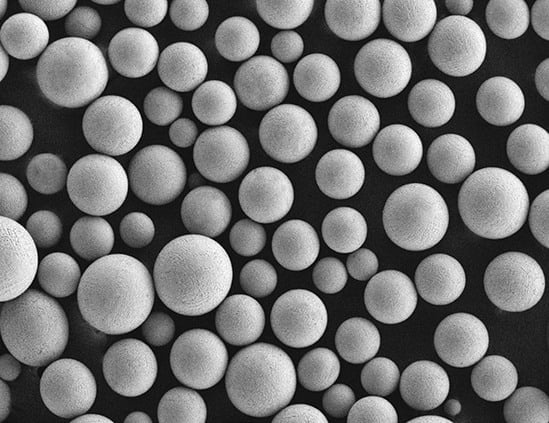

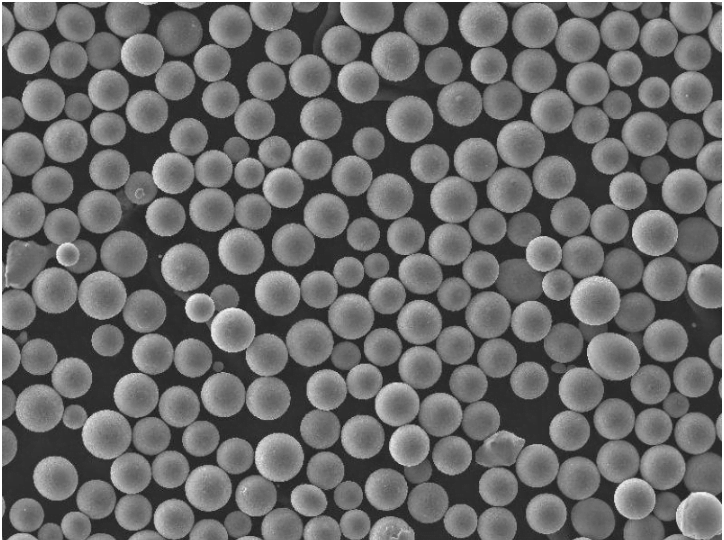

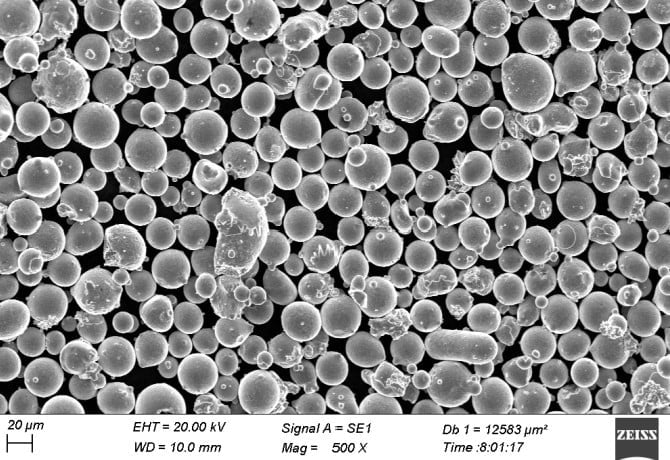

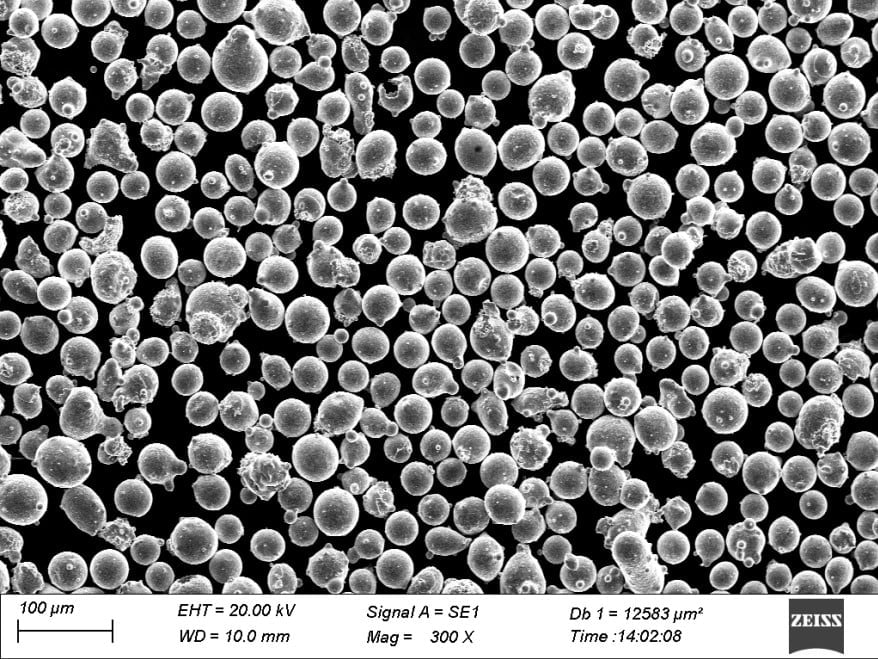

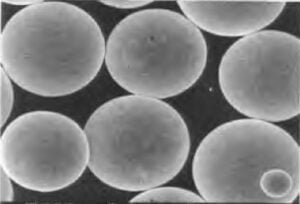

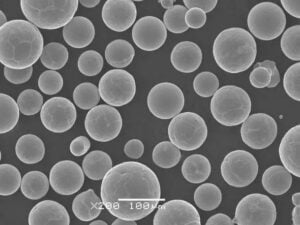

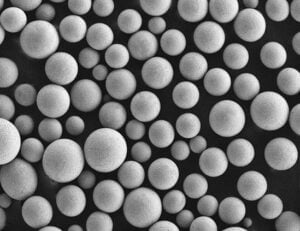

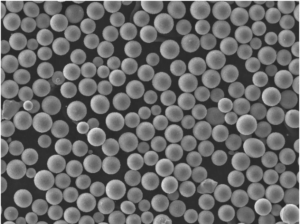

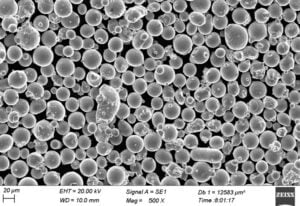

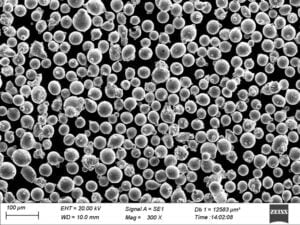

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731