Uncategorized

all colletions

Tungsten Powder Suppliers

Tungsten powder is a key material across several industries due to its high density, strength, and thermal stability. Choosing the right tungsten powder supplier is vital to get the appropriate grade, quality and support for your application. Applications of Tungsten Powder Table 1: Major Applications of Tungsten Powder Industry Applications

Introduction to atomized powders

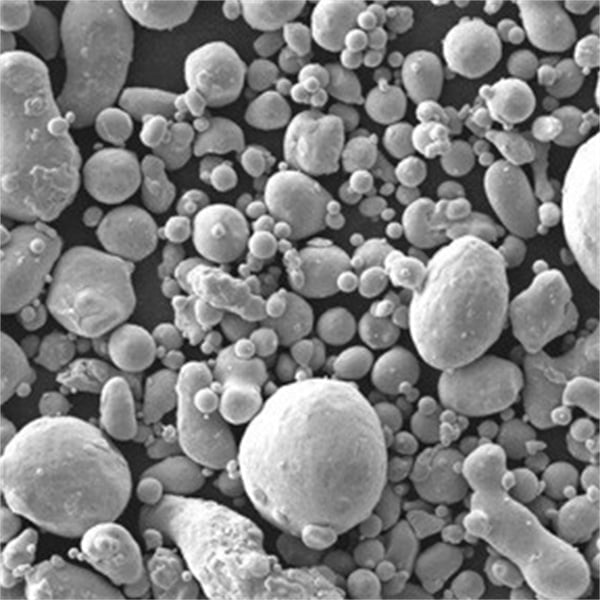

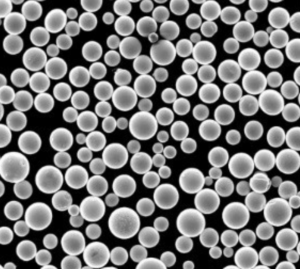

Atomized powder is a type of metal or alloy powder made by atomization, a process where molten metal is turned into fine droplets that solidify into powder particles. This powder production method allows for precise control over powder characteristics like particle size, shape, and composition. Atomized powders have become an

HIP metal powders

HIP or hot isostatic pressing uses heat and pressure to consolidate biocompatible metal powders into complex shapes suitable for hip replacement implants needing a balance of strength, longevity and bone integration ability. This guide covers key alloy types, production methods, characteristics, applications, specifications and comparisons of HIP metal powders for

Metal Alloy Powder Material

Metal alloy powders refer to fine particulate blends of metal elements that when consolidated create high performance components exploiting customized mechanical, thermal, electrical and corrosion properties unavailable in single metal forms. This guide details composition, production methods, characteristics, applications, specifications and comparisons for widely used nickel, aluminum, steel and titanium

Aluminium Alloy Powder

Aluminium alloy powder refers to powder metallurgy forms of aluminium alloys. Aluminium powders find use in various applications due to their lightweight, high strength, corrosion resistance, thermal conductivity, and electrical conductivity. Overview of Aluminium Alloy Powder Aluminium alloy powder is produced by atomization of molten alloys into fine droplets which

Metal Alloy Powders

Metal alloy powders comprise diverse precise blends of metal elements produced through atomization processing into fine spherical particles ideal for advanced fabrication techniques. This guide serves technical professionals a comprehensive reference on metal powder alloy grades spanning typical compositions, mechanical properties data, manufacturing methods, key applications, and leading global suppliers.

Refractory Powder Materials

Refractory Powder Materials represent a specialized class of inorganic non-metallic materials exhibiting extremely high heat resistance used across demanding industries. This comprehensive guide serves technical professionals and buyers understanding all key characteristics of refractory powders – spanning typical composition, critical properties data, manufacturing processes, applications, specifications and suppliers. Overview of

Molybdenum Disilicide Powder

Molybdenum disilicide (MoSi2) is an intermetallic compound valued for high temperature stability, oxidation resistance, and thermal shock characteristics. As a powder, it serves thermal spray, sintering, and composite markets. This guide reviews MoSi2 powder specifications, manufacturing methods, usage examples, vendors, costs, limitations and alternatives to inform materials engineers. Molybdenum Disilicide

3D Printer Aluminum Powder

3d printer aluminum powder serves as a core metal feedstock for powder bed fusion additive manufacturing across aerospace, automotive and general industrial markets. This guide reviews aluminum grades, powder specifications, printing process considerations, sintering methods, mechanical properties, post-processing, applicable components and more around leveraging aluminum powder in laser powder bed

Atomized Metal Powders:Applications, Specifications and Comparisons

Atomized metal powders enable manufacturing methods like additive manufacturing and thermal spray needing feedstock with tailored particle sizes, shapes and metallurgical properties. This guide reviews production processes, specifications, suitable metals, usages, vendor selection and alternatives around commercial atomized powders. atomized metal powders Overview Atomization converts molten metal streams into fine

Tungsten Powder Suppliers

Tungsten powder is a key material across several industries due to its high density, strength, and thermal stability. Choosing the right tungsten powder supplier is

Introduction to atomized powders

Atomized powder is a type of metal or alloy powder made by atomization, a process where molten metal is turned into fine droplets that solidify

HIP metal powders

HIP or hot isostatic pressing uses heat and pressure to consolidate biocompatible metal powders into complex shapes suitable for hip replacement implants needing a balance

Metal Alloy Powder Material

Metal alloy powders refer to fine particulate blends of metal elements that when consolidated create high performance components exploiting customized mechanical, thermal, electrical and corrosion

Aluminium Alloy Powder

Aluminium alloy powder refers to powder metallurgy forms of aluminium alloys. Aluminium powders find use in various applications due to their lightweight, high strength, corrosion

Metal Alloy Powders

Metal alloy powders comprise diverse precise blends of metal elements produced through atomization processing into fine spherical particles ideal for advanced fabrication techniques. This guide

Refractory Powder Materials

Refractory Powder Materials represent a specialized class of inorganic non-metallic materials exhibiting extremely high heat resistance used across demanding industries. This comprehensive guide serves technical

Molybdenum Disilicide Powder

Molybdenum disilicide (MoSi2) is an intermetallic compound valued for high temperature stability, oxidation resistance, and thermal shock characteristics. As a powder, it serves thermal spray,

3D Printer Aluminum Powder

3d printer aluminum powder serves as a core metal feedstock for powder bed fusion additive manufacturing across aerospace, automotive and general industrial markets. This guide

Atomized Metal Powders:Applications, Specifications and Comparisons

Atomized metal powders enable manufacturing methods like additive manufacturing and thermal spray needing feedstock with tailored particle sizes, shapes and metallurgical properties. This guide reviews

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731