Uncategorized

all colletions

Application of Aluminum Silicon 3D Metal Powder in Aerospace

Imagine building intricate metal components layer by layer, with exceptional strength and lightweight properties. That’s the magic of Aluminum Silicon (AlSi) 3D metal powder, a revolutionary material transforming the landscape of additive manufacturing. But what exactly makes this powder so special? Let’s delve into its world, exploring its composition, properties,

Specific classification of Aluminum Alloy 3D Metal Powder

Imagine building intricate objects layer by layer, not with bricks and mortar, but with vaporized metal. This is the magic of 3D printing, and aluminum alloy powders are the tiny metallic soldiers that make it happen. But not all aluminum alloy powders are created equal. Delving into their specific classifications

The application of aluminum alloy 3D metal powder in the aerospace

The quest for lighter, stronger, and more efficient aircraft has been a constant theme in the history of aerospace engineering. In this relentless pursuit, aluminum alloys have long been a champion. However, traditional manufacturing techniques often present limitations in terms of design complexity and material waste. This is where 3D

The Advantages of WAAM 3D Printing Technology

Imagine a 3D printer that can create colossal metal structures, churning out components the size of a car or even a small building. This isn’t science fiction; it’s the reality of WAAM 3D printing technology. Buckle up, because we’re about to delve into the fascinating world of WAAM , exploring

Which metal powders are suitable for WAAM

The world of 3D printing continues to evolve at a breakneck pace, pushing the boundaries of what’s possible. Wire Arc Additive Manufacturing (WAAM) stands as a testament to this innovation, offering a robust and efficient method for constructing large-scale metal structures. But just like a master chef requires the finest

Comparison between DED technology and WAAM technology

Introduction Hook: Imagine crafting complex metal objects layer by layer, with molten metal meticulously deposited to build anything from towering wind turbine components to intricate medical implants. This captivating realm belongs to Directed Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM), two revolutionary metal additive manufacturing (AM) techniques. Problem:

Applications of WAAM in the aerospace field

The aerospace industry thrives on innovation. It’s a constant push to create lighter, stronger, and more efficient vehicles that can conquer the skies and beyond. Enter Wire Arc Additive Manufacturing (WAAM), a revolutionary 3D printing technology that’s rapidly transforming how we build aircraft and spacecraft. Imagine building complex, near-net-shape components

The working steps of WAAM

Imagine building complex metal structures layer by layer, like a culinary master crafting a magnificent cake. That’s the essence of Wire Arc Additive Manufacturing (WAAM), a revolutionary 3D printing technology that’s transforming the way we create metal parts. This comprehensive guide will delve into the captivating world of WAAM, taking

introduction to Wire Arc Additive Manufacturing

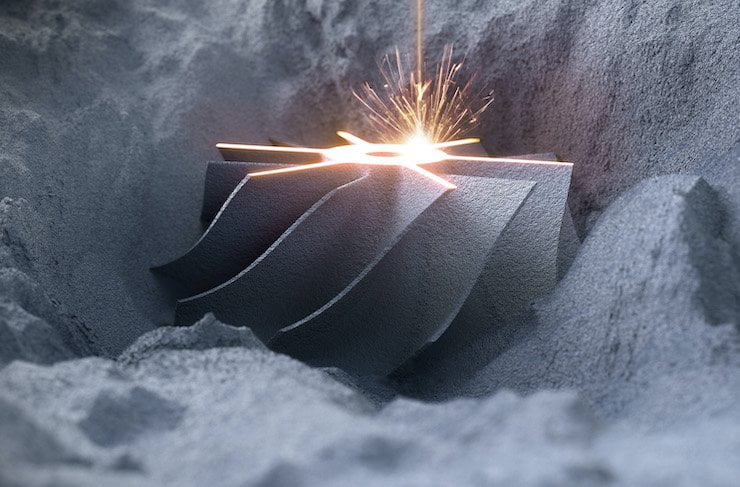

Imagine building large, robust metal parts layer by layer, not through subtractive manufacturing techniques like machining, but by adding material meticulously. This transformative technology is Wire Arc Additive Manufacturing (WAAM), poised to reshape how we create critical components across various industries. The Working Principle of Wire Arc Additive Manufacturing WAAM,

Comparison between Material Jetting and Directed Energy Deposition

Imagine a world where complex objects materialize layer by layer, not through magic, but through the marvels of 3D printing. Within this realm exist two powerful contenders: Material Jetting and Directed Energy Deposition (DED). Both utilize additive manufacturing principles, but their approaches diverge, leading to distinct advantages and limitations. So,

Application of Aluminum Silicon 3D Metal Powder in Aerospace

Imagine building intricate metal components layer by layer, with exceptional strength and lightweight properties. That’s the magic of Aluminum Silicon (AlSi) 3D metal powder, a

Specific classification of Aluminum Alloy 3D Metal Powder

Imagine building intricate objects layer by layer, not with bricks and mortar, but with vaporized metal. This is the magic of 3D printing, and aluminum

The application of aluminum alloy 3D metal powder in the aerospace

The quest for lighter, stronger, and more efficient aircraft has been a constant theme in the history of aerospace engineering. In this relentless pursuit, aluminum

The Advantages of WAAM 3D Printing Technology

Imagine a 3D printer that can create colossal metal structures, churning out components the size of a car or even a small building. This isn’t

Which metal powders are suitable for WAAM

The world of 3D printing continues to evolve at a breakneck pace, pushing the boundaries of what’s possible. Wire Arc Additive Manufacturing (WAAM) stands as

Comparison between DED technology and WAAM technology

Introduction Hook: Imagine crafting complex metal objects layer by layer, with molten metal meticulously deposited to build anything from towering wind turbine components to intricate

Applications of WAAM in the aerospace field

The aerospace industry thrives on innovation. It’s a constant push to create lighter, stronger, and more efficient vehicles that can conquer the skies and beyond.

The working steps of WAAM

Imagine building complex metal structures layer by layer, like a culinary master crafting a magnificent cake. That’s the essence of Wire Arc Additive Manufacturing (WAAM),

introduction to Wire Arc Additive Manufacturing

Imagine building large, robust metal parts layer by layer, not through subtractive manufacturing techniques like machining, but by adding material meticulously. This transformative technology is

Comparison between Material Jetting and Directed Energy Deposition

Imagine a world where complex objects materialize layer by layer, not through magic, but through the marvels of 3D printing. Within this realm exist two

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731