Metal Powder for Transportation

Table of Contents

Overview

Metal powders are revolutionizing the transportation industry by offering advanced materials that enhance performance, reduce weight, and improve fuel efficiency. These fine particles of metal, meticulously engineered, are used in a variety of applications from automotive components to aerospace parts. This article delves into the specifics of metal powders, exploring their types, compositions, characteristics, applications, and more. We’ll look at popular metal powder models, provide detailed tables for quick reference, and answer frequently asked questions.

What is Metal Powder?

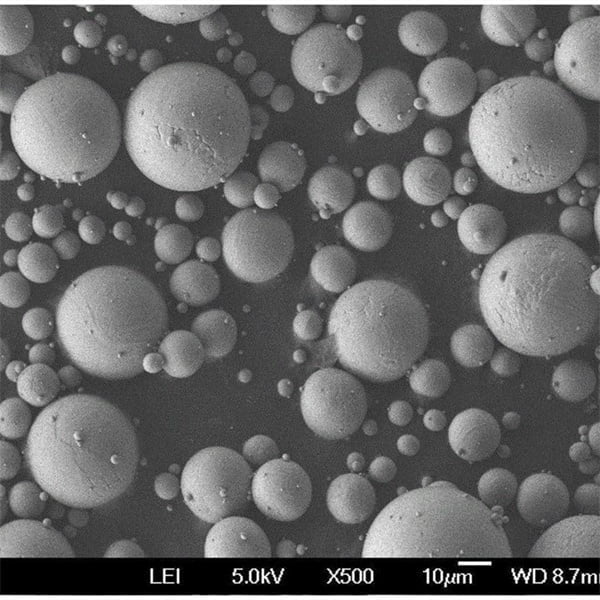

Metal powder refers to finely divided particles of metals or alloys that are used as raw materials in various manufacturing processes. These powders can be produced through several methods including atomization, reduction, and electrolysis. They are used extensively in powder metallurgy, additive manufacturing, and thermal spray applications.

Why is Metal Powder Important for Transportation?

In transportation, the use of metal powders offers several advantages:

- Lightweight Components: Reducing the weight of vehicles leads to better fuel efficiency and lower emissions.

- Enhanced Strength: Certain metal powders provide high strength-to-weight ratios, crucial for automotive and aerospace applications.

- Complex Geometries: Metal powders enable the production of complex shapes and structures through additive manufacturing, which would be impossible or very costly with traditional methods.

Types of Metal Powders for Transportation

Here’s a look at some of the most commonly used metal powders in the transportation sector:

Aluminum Powder

- Composition: Pure aluminum or aluminum alloys

- Characteristics: Lightweight, corrosion-resistant, good thermal and electrical conductivity

- Applications: Automotive engine components, aerospace parts

Titanium Powder

- Composition: Pure titanium or titanium alloys

- Characteristics: High strength-to-weight ratio, excellent corrosion resistance

- Applications: Aircraft components, automotive parts

Stainless Steel Powder

- Composition: Iron-based alloys with chromium, nickel, and molybdenum

- Characteristics: Corrosion resistance, high strength, good machinability

- Applications: Automotive exhaust systems, structural parts

Nickel Alloy Powder

- Composition: Nickel-based alloys with chromium, molybdenum, and cobalt

- Characteristics: High temperature resistance, corrosion resistance

- Applications: Turbine blades, engine components

Copper Powder

- Composition: Pure copper or copper alloys

- Characteristics: Excellent electrical and thermal conductivity

- Applications: Electrical components, heat exchangers

Iron Powder

- Composition: Pure iron or iron alloys

- Characteristics: Magnetic properties, good strength

- Applications: Automotive parts, brake pads

Cobalt Powder

- Composition: Pure cobalt or cobalt alloys

- Characteristics: High temperature resistance, wear resistance

- Applications: Aerospace components, medical implants

Magnesium Powder

- Composition: Pure magnesium or magnesium alloys

- Characteristics: Extremely lightweight, good machinability

- Applications: Aerospace parts, automotive components

Tungsten Powder

- Composition: Pure tungsten or tungsten alloys

- Characteristics: High density, high melting point

- Applications: Aerospace components, radiation shielding

Zinc Powder

- Composition: Pure zinc or zinc alloys

- Characteristics: Good corrosion resistance, low melting point

- Applications: Galvanization, batteries

Composition of Metal Powder for Transportation

| Type | Main Components | Secondary Components | Properties |

|---|---|---|---|

| Aluminum Powder | Aluminum | Silicon, Magnesium | Lightweight, Corrosion-resistant |

| Titanium Powder | Titanium | Aluminum, Vanadium | High Strength-to-Weight Ratio |

| Stainless Steel Powder | Iron, Chromium, Nickel | Molybdenum, Carbon | Corrosion-resistant, High Strength |

| Nickel Alloy Powder | Nickel, Chromium, Molybdenum | Cobalt, Iron | High Temperature Resistance |

| Copper Powder | Copper | Zinc, Tin | Excellent Electrical Conductivity |

| Iron Powder | Iron | Carbon, Silicon | Magnetic Properties, Good Strength |

| Cobalt Powder | Cobalt | Chromium, Tungsten | High Temperature Resistance, Wear Resistance |

| Magnesium Powder | Magnesium | Aluminum, Zinc | Extremely Lightweight, Good Machinability |

| Tungsten Powder | Tungsten | Carbon, Nickel | High Density, High Melting Point |

| Zinc Powder | Zinc | Aluminum, Copper | Good Corrosion Resistance, Low Melting Point |

Characteristics of Metal Powder for Transportation

Each type of metal powder brings unique characteristics to the table. Here’s a closer look at what makes these powders ideal for transportation applications:

- Aluminum Powder: Its lightweight nature makes it perfect for reducing the overall weight of vehicles without compromising strength.

- Titanium Powder: Offers exceptional strength and resistance to corrosion, making it suitable for high-performance parts in both aerospace and automotive industries.

- Stainless Steel Powder: Known for its durability and resistance to rust, it’s often used in parts exposed to harsh environments.

- Nickel Alloy Powder: Withstands high temperatures and corrosive environments, ideal for engine components.

- Copper Powder: Its excellent conductivity makes it invaluable for electrical components and thermal management systems.

- Iron Powder: Commonly used for its magnetic properties and strength, essential in various automotive parts.

- Cobalt Powder: High wear resistance and temperature stability make it perfect for demanding aerospace applications.

- Magnesium Powder: Its light weight significantly contributes to weight reduction in vehicles, enhancing fuel efficiency.

- Tungsten Powder: Known for its density and ability to withstand extreme temperatures, it’s often used in high-stress components.

- Zinc Powder: Its corrosion resistance makes it suitable for protective coatings and batteries.

Applications of Metal Powder for Transportation

| Application | Metal Powder Type | Details |

|---|---|---|

| Automotive Engine Components | Aluminum, Iron, Titanium | Lightweight and strong materials to improve performance |

| Aerospace Parts | Titanium, Cobalt, Nickel | High strength-to-weight ratio and temperature resistance |

| Electrical Components | Copper, Aluminum | Excellent conductivity for wiring and connectors |

| Heat Exchangers | Copper, Aluminum | Efficient thermal management in vehicles |

| Brake Pads | Iron, Copper | Enhanced friction and durability |

| Turbine Blades | Nickel, Titanium | High temperature resistance for engine efficiency |

| Galvanization | Zinc, Aluminum | Corrosion protection for vehicle bodies |

| Medical Implants | Cobalt, Titanium | Biocompatible and strong materials |

| Radiation Shielding | Tungsten, Lead | High density materials to protect against radiation |

| Fuel Cells | Platinum, Nickel | Catalytic properties for efficient energy conversion |

Specifications, Sizes, Grades, and Standards of Metal Powder for Transportation

| Metal Powder Type | Specifications | Sizes | Grades | Standards |

|---|---|---|---|---|

| Aluminum Powder | ASTM B928 | 5-100 microns | 6061, 7075 | ASTM, ISO |

| Titanium Powder | ASTM B348 | 10-150 microns | Grade 5, Grade 23 | ASTM, AMS |

| Stainless Steel Powder | ASTM A564 | 10-150 microns | 304L, 316L | ASTM, ISO |

| Nickel Alloy Powder | AMS 5666 | 15-200 microns | Inconel 625, 718 | AMS, ASTM |

| Copper Powder | ASTM B212 | 1-100 microns | C11000, C21000 | ASTM, ISO |

| Iron Powder | ASTM B839 | 10-150 microns | 1000, 4000 | ASTM, ISO |

| Cobalt Powder | AMS 5842 | 5-100 microns | MP35N, L605 | AMS, ASTM |

| Magnesium Powder | ASTM B92 | 5-100 microns | AZ31, AZ91 | ASTM, AMS |

| Tungsten Powder | ASTM B777 | 0.5-100 microns | W1, W2 | ASTM, ISO |

| Zinc Powder | ASTM B846 | 1-100 microns | Zn98, Zn99 | ASTM, ISO |

Suppliers and Pricing Details of Metal Powder for Transportation

| Supplier | Metal Powder Type | Price Range (per kg) | Availability |

|---|---|---|---|

| Höganäs AB | Iron, Stainless Steel | $15 – $50 | Global |

| GKN Powder Metallurgy | Aluminum, Copper, Nickel | $20 – $80 | Global |

| Carpenter Technology | Titanium, Cobalt | $50 – $200 | Global |

| LPW Technology | Nickel, Stainless Steel | $30 – $100 | Global |

| AP&C | Titanium, Aluminum | $40 – $150 | Global |

| American Elements | Magnesium, Tungsten | $20 – $100 | Global |

| ECKA Granules | Zinc, Copper | $10 – $60 | Global |

| PyroGenesis | Aluminum, Titanium | $35 – $120 | Global |

| Sandvik | Stainless Steel, Nickel | $25 – $90 | Global |

| Arcam AB | Titanium, Cobalt | $45 – $180 | Global |

Pros and Cons of Metal Powders for Transportation

| Metal Powder Type | Advantages | Disadvantages |

|---|---|---|

| Aluminum Powder | Lightweight, corrosion-resistant | Lower strength compared to some metals |

| Titanium Powder | High strength-to-weight ratio, corrosion-resistant | Expensive, difficult to machine |

| Stainless Steel Powder | Corrosion-resistant, durable | Heavier than aluminum and titanium |

| Nickel Alloy Powder | High temperature resistance, corrosion-resistant | Expensive |

| Copper Powder | Excellent electrical conductivity | Prone to oxidation |

| Iron Powder | Magnetic properties, strong | Corrosion if not protected |

| Cobalt Powder | High temperature and wear resistance | Expensive, brittle |

| Magnesium Powder | Extremely lightweight | Flammable, corrosion issues |

| Tungsten Powder | High density, high melting point | Very heavy, expensive |

| Zinc Powder | Good corrosion resistance, low melting point | Lower strength |

Comparing Metal Powders for Transportation Applications

When it comes to choosing the right metal powder for a specific transportation application, it’s essential to weigh the pros and cons of each type. For instance, if you’re looking for lightweight materials to improve fuel efficiency, aluminum and magnesium powders are excellent choices. On the other hand, if you need materials that can withstand high temperatures and harsh environments, titanium and nickel alloy powders are more suitable despite their higher costs.

Detailed Descriptions of Specific Metal Powder Models

1. Höganäs Ancorsteel 1000B

- Type: Iron Powder

- Composition: Pure iron

- Applications: Automotive parts, structural components

- Properties: High strength, good machinability

2. GKN AM™ Aluminum Alloy 6061

- Type: Aluminum Powder

- Composition: Aluminum with silicon and magnesium

- Applications: Engine components, lightweight structures

- Properties: Lightweight, corrosion-resistant

3. Carpenter Puris™ 5+

- Type: Titanium Powder

- Composition: Titanium with aluminum and vanadium

- Applications: Aerospace components, medical implants

- Properties: High strength-to-weight ratio, biocompatible

4. LPW Inconel 718

- Type: Nickel Alloy Powder

- Composition: Nickel with chromium, molybdenum, and niobium

- Applications: Turbine blades, engine parts

- Properties: High temperature resistance, corrosion-resistant

5. AP&C Ti-6Al-4V

- Type: Titanium Powder

- Composition: Titanium with aluminum and vanadium

- Applications: Aerospace parts, automotive components

- Properties: High strength, lightweight

6. Sandvik Osprey™ 316L

- Type: Stainless Steel Powder

- Composition: Iron with chromium, nickel, and molybdenum

- Applications: Structural parts, medical devices

- Properties: Corrosion-resistant, high strength

7. American Elements Magnesium AZ91

- Type: Magnesium Powder

- Composition: Magnesium with aluminum and zinc

- Applications: Lightweight automotive parts, aerospace components

- Properties: Extremely lightweight, good machinability

8. ECKA Granules Copper C11000

- Type: Copper Powder

- Composition: Pure copper

- Applications: Electrical components, heat exchangers

- Properties: Excellent electrical conductivity

9. PyroGenesis Plasma Atomized Aluminum 7075

- Type: Aluminum Powder

- Composition: Aluminum with zinc and magnesium

- Applications: High-strength aerospace components, automotive parts

- Properties: Lightweight, high strength

10. Arcam Titanium Ti-6Al-4V ELI

- Type: Titanium Powder

- Composition: Titanium with aluminum and vanadium

- Applications: Medical implants, aerospace components

- Properties: Biocompatible, high strength

FAQ

| Question | Answer |

|---|---|

| What are metal powders used for in transportation? | Metal powders are used to create lightweight, high-strength components for vehicles and aircraft. |

| How are metal powders made? | Metal powders are produced through methods like atomization, reduction, and electrolysis. |

| Which metal powder is the best for lightweight applications? | Aluminum and magnesium powders are best for lightweight applications due to their low density. |

| What are the benefits of using titanium powder? | Titanium powder offers a high strength-to-weight ratio and excellent corrosion resistance. |

| Can metal powders be recycled? | Yes, many metal powders can be recycled, reducing waste and environmental impact. |

| Are metal powders safe to handle? | Proper safety measures should be followed, as some metal powders can be hazardous if inhaled or if they react with other substances. |

| What industries use metal powders the most? | The automotive and aerospace industries are the primary users of metal powders, but they are also used in electronics, medical devices, and more. |

| How do metal powders improve fuel efficiency? | By reducing the weight of components, metal powders help improve fuel efficiency and reduce emissions. |

| What is the difference between pure metal powders and alloy powders? | Pure metal powders consist of a single metal, while alloy powders are composed of two or more metals, offering combined properties. |

| Where can I buy metal powders? | Metal powders can be purchased from suppliers like Höganäs AB, GKN Powder Metallurgy, and Carpenter Technology. |

Conclusion

Metal powders are a cornerstone of modern transportation technology, offering materials that are not only strong and durable but also lightweight and efficient. By understanding the various types, compositions, and applications of these powders, manufacturers can optimize their designs and processes, leading to better performance and sustainability. Whether you’re looking to enhance fuel efficiency, reduce emissions, or create complex components, metal powders provide the versatility and capability needed to meet the demands of the transportation industry.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731