Plasma Rotating Electrode Process (PREP) for Superior Metal Powders

Table of Contents

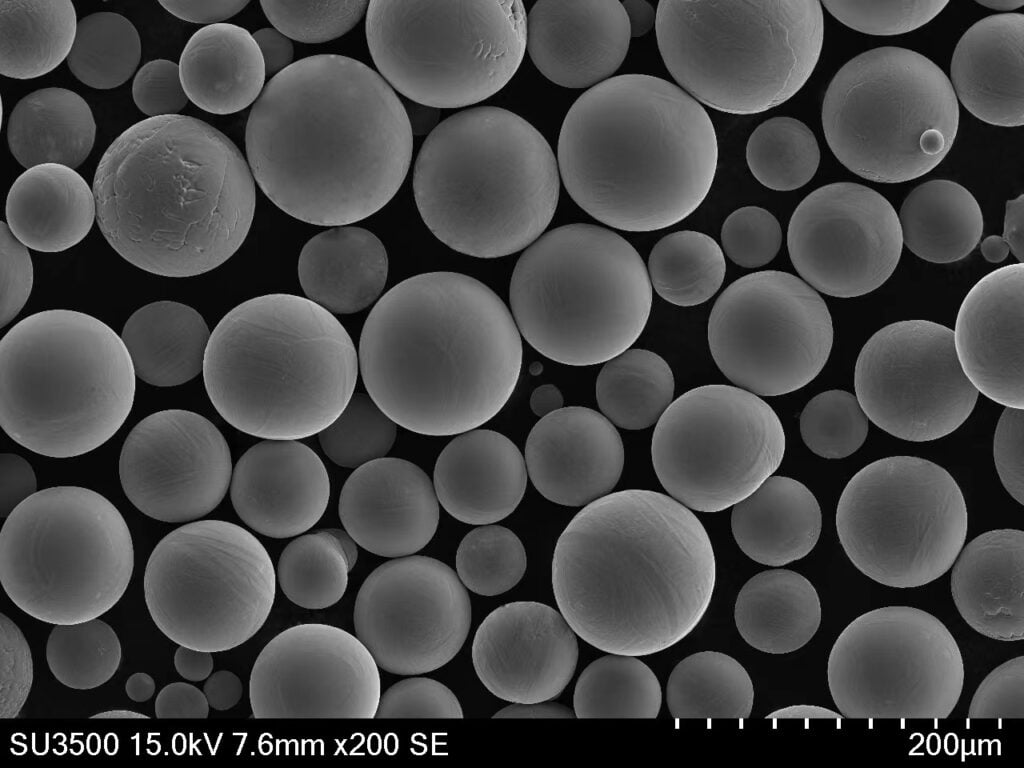

Imagine a world where metal components are crafted not through traditional means, but by meticulously building them layer by layer using tiny, perfectly spherical metal particles. This futuristic vision is the cornerstone of Additive Manufacturing (AM), also known as 3D printing. But what about the magic ingredient that brings these intricate objects to life? Enter the Plasma Rotating Electrode Process (PREP), a revolutionary technique for producing high-quality metal powders specifically designed for AM applications.

The Essence of PREP: A High-Tech Ballet

PREP operates like a meticulously choreographed ballet within a controlled environment. Here’s a breakdown of the key steps:

- The Stage: A sealed chamber filled with an inert gas, typically argon or helium, ensures minimal contamination during the process.

- The Star Performer: A rod of the desired metal, acting as the electrode, takes center stage.

- The Spotlight: An intense plasma torch, generated by ionizing the inert gas, bathes the electrode tip in extreme heat, causing it to melt.

- The Grand Jeté: As the electrode spins at high speeds, centrifugal force takes over, flinging molten metal droplets outwards.

- The Grand Finale: These droplets rapidly cool and solidify in the inert gas atmosphere, transforming into near-perfect spherical metal particles – the coveted metal powder for AM.

The Allure of PREP Powders: A Cut Above the Rest

PREP-derived metal powders boast a unique set of characteristics that make them ideal for AM:

- Spherical Shape: Unlike irregularly shaped powders, PREP particles are near-perfect spheres. This translates to superior flowability within AM machines, leading to consistent layer formation and a smoother printing experience.

- High Purity: The controlled environment of the PREP chamber minimizes oxygen and other gas pickup, resulting in metal powders with exceptional purity. This translates to superior mechanical properties and fewer defects in the final printed part.

- Narrow Size Distribution: PREP powders exhibit a tight range of particle sizes. This consistency ensures even packing density during printing, minimizing internal voids and enhancing the overall strength of the finished product.

- Low Internal Porosity: The rapid solidification process inherent to PREP minimizes the formation of internal pores within the metal particles. This translates to denser and more robust printed parts.

A Menagerie of Metal Marvels: Exploring PREP Powders

The versatility of PREP shines through in the vast array of metal powders it can produce. Let’s delve into some of the most sought-after examples:

1. Titanium Powders (Ti-6Al-4V, Ti-2Al-Nb, etc.)

- Applications: Aerospace components, medical implants, sporting goods

- Why PREP is Ideal: PREP delivers high-purity titanium powders with excellent biocompatibility, crucial for medical implants. Additionally, the process ensures minimal oxygen pickup, which is vital for the strength and fatigue resistance required in aerospace parts.

2. Nickel-based Superalloys (Inconel 625, Inconel 718, etc.)

- Applications: High-temperature components in jet engines, gas turbines, and rocket engines

- Why PREP is Ideal: PREP-manufactured superalloy powders retain their exceptional high-temperature strength and oxidation resistance, making them perfect for withstanding the harsh environments encountered in jet engines and turbines.

3. Stainless Steel Powders (316L, 17-4PH, etc.)

- Applications: Surgical instruments, chemical processing equipment, food-grade components

- Why PREP is Ideal: PREP offers stainless steel powders with superior corrosion resistance and biocompatibility, ideal for applications in healthcare and the food industry. The near-spherical shape of the powders also facilitates intricate geometries often required in surgical tools.

4. Aluminum Powders (AlSi10Mg, AlSi7Mg0.3, etc.)

- Applications: Automotive components, consumer electronics housings, lightweight aerospace parts

- Why PREP is Ideal: PREP-produced aluminum powders offer excellent flowability and a good balance between strength and weight, making them perfect for applications where lightweighting is crucial.

5. Cobalt-Chrome Alloys (CoCrMo)

- Applications: Biomedical implants, joint replacements

- Why PREP is Ideal: The high purity and biocompatibility of PREP-derived CoCrMo powders make them a reliable choice for demanding medical applications like joint replacements.

6. Copper Powders

- Applications: Heat sinks, electrical components, electromagnetic shielding

- Why PREP is Ideal: The high thermal conductivity of PREP copper powders makes them ideal for applications requiring efficient heat dissipation.

7. Refractory Metal Powders (Tungsten, Molybdenum, etc.)

- Applications: High-temperature furnace components, rocket nozzles, welding electrodes

- Why PREP is Ideal: PREP excels at creating refractory metal powders with high melting points and excellent thermal stability, making them suitable for withstanding the extreme temperatures encountered in rocket nozzles and furnaces.

8. Precious Metal Powders (Gold, Silver, Platinum, etc.)

- Applications: Jewelry, electronics, dental applications

- Why PREP is Ideal: The tight size distribution and high purity of PREP precious metal powders ensure consistent material properties and minimize waste during AM processes, making them ideal for high-value applications like jewelry and electronics.

9. Magnesium Powders

- Applications: Lightweight aerospace components, biodegradable implants

- Why PREP is Ideal: PREP-derived magnesium powders offer exceptional weight savings and good biodegradability, making them attractive for applications where weight reduction and biocompatibility are paramount.

10. Amorphous Metal Powders

- Applications: High-performance transformers, magnetic shielding, sporting goods

- Why PREP is Ideal: The rapid solidification inherent to PREP allows for the creation of amorphous metal powders with unique properties like high strength, excellent wear resistance, and superior magnetic properties.

Beyond the Glitter: A Balanced View of PREP Powders

While PREP powders offer a compelling array of benefits, it’s important to acknowledge some considerations:

- Cost: The complex setup and energy requirements of the PREP process can translate to higher powder costs compared to some alternative methods.

- Production Rate: PREP production can be slower compared to other techniques, impacting lead times for high-volume applications.

- Material Limitations: While PREP is versatile, it might not be suitable for all types of metals, particularly those with high vapor pressures or reactivity.

The PREP vs. The Rest: Weighing Your Options

When choosing a metal powder for AM, PREP faces competition from other techniques like gas atomization (GA) and water atomization (WA). Here’s a breakdown to help you decide:

| Metric | PREP | Gas Atomization (GA) | Water Atomization (WA) |

|---|---|---|---|

| Shape | Highly spherical | Mostly spherical, some satellites | Irregular shapes |

| Purity | Very high | High | Moderate |

| Size Distribution | Narrow | Moderately narrow | Wide |

| Porosity | Low | Moderate | High |

| Cost | High | Moderate | Low |

| Production Rate | Moderate | High | High |

PREP emerges as the champion for applications demanding exceptional powder quality, tight tolerances, and superior mechanical properties in the final printed part. However, for less critical applications or high-volume production, GA or WA might offer a more cost-effective solution.

Finding Your Perfect Match: The PREP Powder Supplier Landscape

Now that you’re familiar with the magic of PREP powders, let’s explore the landscape of potential suppliers:

- Met3DP: A leading manufacturer offering a wide range of high-quality metal powders for AM, including innovative alloys like TiNi, TiTa, and CoCrMo.

- Höganäs: A global provider of metal powders known for their consistent quality and expertise in a variety of materials.

- LPW Technology: A prominent player in the AM industry, LPW also offers a selection of PREP-manufactured metal powders for their own powder bed fusion systems.

- Carpenter Additive: A specialist in high-performance materials, Carpenter Additive provides PREP powders for demanding applications in aerospace and medical sectors.

- AM powders: This US-based company focuses on delivering high-purity metal powders for various AM technologies, including PREP powders.

Pricing can vary depending on the specific metal powder, order quantity, and supplier. It’s recommended to contact multiple suppliers to compare pricing and request quotes based on your specific needs.

Frequently Asked Questions (FAQ) About PREP Metal Powders

Q: What are the size ranges of PREP metal powders?

A: PREP powders typically range in size from 10 to 150 microns, with the specific range depending on the desired application and the capabilities of the AM machine being used.

Q: Can I use PREP powders with different AM technologies?

A: Yes, PREP powders are compatible with various AM processes, including laser powder bed fusion (LPBF), electron beam melting (EBM), and binder jetting. However, it’s crucial to consult the machine manufacturer’s recommendations for compatible

Q: Are PREP metal powders safe to handle?

A: Metal powders in general, including those produced by PREP, can pose health risks if inhaled. Proper safety precautions like using a fume hood and wearing personal protective equipment (PPE) are essential when handling these powders.

Q: How does the surface roughness of PREP powders compare to other methods?

A: PREP powders generally have a smoother surface finish compared to powders produced by gas atomization or water atomization. This smoother surface can contribute to improved flowability and better packing density during AM, leading to potentially denser and stronger printed parts.

Q: What are some emerging applications for PREP metal powders?

A: The future of PREP powders is bright! Here are some exciting possibilities:

- Bioprinting: The exceptional biocompatibility of certain PREP powders makes them promising candidates for creating intricate structures for tissue engineering and regenerative medicine.

- Multi-material Printing: Researchers are exploring the potential of using PREP powders in combination with other materials to create components with unique functional properties.

- Space Exploration: The ability of PREP to produce high-performance metal powders is attracting interest for manufacturing lightweight and robust components for spacecraft.

The Final Verdict: PREP Powders – A Powerful Tool for AM

The Plasma Rotating Electrode Process (PREP) stands out as a sophisticated technique for creating high-quality metal powders. These powders offer a unique combination of benefits, including exceptional shape, purity, and size distribution, making them ideal for Additive Manufacturing applications demanding superior performance. While factors like cost and production rate require consideration, PREP remains a powerful tool in the AM arsenal, pushing the boundaries of what’s possible in the exciting world of 3D printing.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731