Powder Bed 3D Printers

Table of Contents

Overview

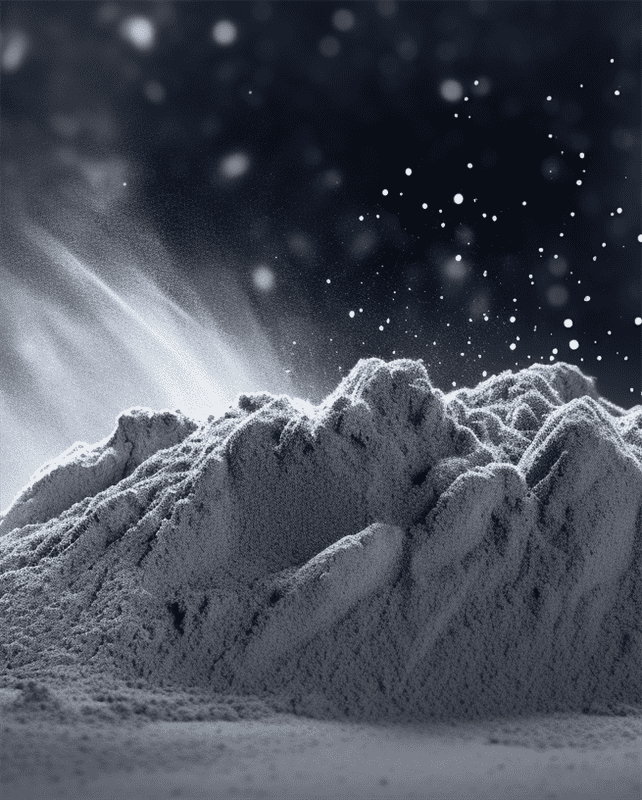

powder bed 3d printer is an additive manufacturing technology well suited to processing high performance engineering thermoplastics and metals that cannot be printed easily with extrusion based methods. A laser or electron beam selectively fuses regions of a powder bed layer-by-layer based on CAD data to construct complex 3D objects.

The main sub-categories are:

Polymer Powder Bed Fusion (PBF) utilizing a CO2 or IR laser, and Metal Powder Bed Fusion (MPBF) employing fiber lasers or electron beams. Both offer competitive part functionality impossible with traditional manufacturing techniques in terms of lightweight design, assembly consolidation, mass customization and performance enhancement.

This guide provides a technical overview of various powder bed 3D printing technologies and materials along with applications, system considerations and future trends.

Types of Powder Bed 3D Printers

There are several additive manufacturing equipment types which harness the powder bed fusion approach:

| Category | Description |

|---|---|

| Selective Laser Sintering (SLS) | Sinters polymer powder using a CO2 laser |

| Multi Jet Fusion (MJF) | Binds plastic powder with inkjetted fusing and detailing agents |

| Selective Laser Melting (SLM) | Full welding together of metallic powder by fiber laser |

| Direct Metal Laser Sintering (DMLS) | Fuses metal powder through laser melting |

| Electron Beam Melting (EBM) | Uses electron beam in vacuum to melt metal powder beds |

Polymer Powder Bed Fusion Printers

Selective laser sintering (SLS) systems distribute a thin layer of fine polymer powder across a build chamber and apply thermal energy from a CO2 laser beam according to each cross section from the 3D CAD model. The powder melts or sinters together upon heating and solidifies during cooling to become the object.

Popular materials for SLS include:

- Nylon (PA12, PA11, PA6)

- Thermoplastic Elastomers (TPE)

- TPU and other advanced flexible resins

Leading SLS printer companies include EOS, 3D Systems, Farsoon and Ricoh.

Multi Jet Fusion (MJF) also utilizes polymer powder beds, but a fusing agent and detailing agent are selectively deposited by inkjet printheads across the layers along with infrared heating to achieve high resolution prints. It enables multi-material and multi-color objects. Common MJF resins:

- HP 3D High Reusability PA12

- HP 3D High Reusability PA11

- HP 3D High Reusability TPA

HP is the foremost provider of MJF technology today through its Jet Fusion series. Desktop Metal has also released the Fiber AM system based on MJF.

Metal Powder Bed Fusion Printers

Selective Laser Melting (SLM) equipment focuses extremely precise fiber laser energy in an inert gas environment across thin layers of metallic powder to fully melt and fuse particles into dense structures layer by layer based directly on CAD geometries.

Electron Beam Melting (EBM) printers use a powerful electron beam as the consolidation heat source to fully melt metal powder particles across each layer in a vacuum atmosphere. The fast processing leads to components with properties approaching cast materials.

Common alloys for MPBF include:

- Stainless steel (316L, 17-4PH, 15-5)

- Tool steel (H13, S7)

- Titanium alloys (Ti-6Al-4V)

- Aluminum alloys (AlSi10Mg)

- Nickel superalloys (Inconel 718)

- Cobalt chromium (CoCr)

All leading metal AM equipment suppliers like EOS, Renishaw, 3D Systems, GE and SLM Solutions offer powder bed fusion machines.

Print Process for powder bed 3d printer

The generic additive manufacturing workflow steps common across the powder bed fusion variants:

- Import CAD model and orient part optimally

- Virtually slice and generate laser scanning paths

- Spread measured quantity of powder evenly across build area

- Selectively melt material according to section outline using laser or ebeam

- Lower build plate and recoat new layer powder

- Repeat layering cycle until full object and supports are built

- Remove object from powder cake and recover unmelted regions

- Post process parts – clean, heat treat, machine etc.

All powder bed processes demand extensive post processing like supports removal, surface machining and treatments before functional use.

Materials for powder bed 3d printer

Polymer Powders Properties

| Material | Density | Tensile Strength | Elongation % | Uses |

|---|---|---|---|---|

| PA12 | 0.9-1.1 g/cm3 | 45-65 MPa | 15-50% | General purpose SLS prototyping polymer |

| TPU 92A | 1.1-1.3 g/cm3 | > 6 MPa | 220-240% | Flexible, rubberlike parts via SLS |

| PEEK | 1.3-1.4 g/cm3 | 100 MPa | 30-60% | High strength engineering plastic parts |

Metal Powder Types

| Alloy | Density | Melting Point | Uses |

|---|---|---|---|

| Aluminum AlSi10Mg | 2.7 g/cm3 | 600°C | Lightweight aero and auto components |

| Titanium Ti-6Al-4V | 4.4 g/cm3 | 1655°C | Implants and high strength structures |

| Tool Steel H13 | 7.7 g/cm3 | 1320°C | Durable tooling for molding and extrusion |

| Stainless Steel 316L | 8.0 g/cm3 | 1375°C | Corrosion resistant vessels, valves, hardware |

| Inconel 718 | 8.2 g/cm3 | 1260-1336°C | Heat and creep resistant aeroengine parts at high temps |

Applications of powder bed 3d printer

Polymer Parts

- Functional prototypes with properties resembling real world plastics

- Customized consumer goods like cell phone cases or footwear

- Automotive interiors and lighting components

- Induction molds and jigs & fixtures

- High temp molds and ducting for chemicals

Metal Components

- Turbine blades and fuel injector prototypes for aerospace

- Bio-compatible titanium implants for knees, hips, cranial and spinal surgery

- Lightweight chassis, brakes and power train parts for racing cars and aircraft

- Conformal cooling channels integrated into injection molds

- Custom dental copings substructures and bridges

- Heat resistant exhaust manifolds and tooling inserts

Buyer’s Guide for Powder Bed 3D Printers

Selecting an ideal powder bed fusion system depends on:

| Criteria | Key Considerations |

|---|---|

| Build Envelope | Maximum part dimensions possible. From 5 inches to 500 mm+ |

| Materials | Available resins from polymers to reactive metals that meet application needs |

| Precision | X-Y resolutions from ~100 microns down to 5 microns for fine details |

| Surface Finish | Side wall quality ranging from 15 microns to 150+. May require post machining. |

| Automation | Manual or automated powder handling. Closed-loop processing preferred. |

| Software | Generative design integration for topology optimization. Quick slicing. |

| Price Range | Upfront system costs from $100K to over $1M. Consider operating costs too. |

| Lead Times | Installation and delivery schedules. Operator training durations. |

Some leading models span:

Starter – EOS Formiga P110 SLS system, $100K

Professional – 3D Systems DMP Factory 500, $400K

Industrial – GE Additive X Line 2000R, >$1M

Future Outlook

Powder bed fusion systems will continue evolving with:

- Larger build envelopes over 500 mm long

- Additional polymer materials like PEKK and PPSF

- Higher mechanical performance alloys

- Improved powder recyclability and closed-loop processing

- Breakthrough surface finishes without machining

- Integrated real-time melt pool monitoring and adjustments

- Additional hybrid systems with inline quality assurance

- Dramatically increased productivity through higher laser power and faster scan speeds

As technical barriers are overcome and production costs optimized, AM will transform manufacturing across sectors from aerospace, medical devices and automotive to consumer products by enabling distributed, decentralized fabrication of end-use components at commercial volumes.

FAQs

Q: How expensive are powder bed fusion metal 3D printing machines compared to plastic systems?

A: Industrial metal powder bed printers range from $300,000 to over $1 million while polymer-based equipment starts at $100,000. Operating costs are also 5-10X higher for metal materials and inert processing.

Q: What size parts can be 3D printed with powder bed fusion technology?

A: Metal machines accommodate build volumes up to 500 x 500 x 500 mm cubes typically while polymers go up to 800 x 500 x 375 mm dimensions. Larger envelopes over a meter long are also available.

Q: What materials can be processed using powder bed 3D printing?

A: All high performance and engineering-grade thermoplastics like PEEK, ULTEM, PPSF can be printed which are difficult for FDM extrusion. On metals, stainless steels, titanium and nickel alloys, tool steels, cobalt chrome and more qualify.

Q: How good is the accuracy and surface finish coming off a powder bed printer before any post-processing?

A: Dimensional accuracy after post-processing is around ±0.1-0.3% while tolerances below 50 microns are possible. As-printed surface roughness ranges considerably between 15-150 microns before any finishing.

Q: Which powder bed fusion process offers the fastest build speeds – SLS, DMLS or EBM?

A: Electron beam melting (EBM) offers extremely high build rates up to 40 cm3/hour which allows very high productivity. DMLS offers moderate speeds while SLS is comparatively quite slow.

Q: How sustainable is powder bed AM compared to machining metals and plastics?

A: All powder bed technologies reuse over 90% of unmelted powder after builds for recycling. Lightweighting optimized geometries also save materials. Energy usage remains a focus area.

Q: What factors lead to pricing of powder bed fusion printing services?

A: Material costs, build time, labor, finishing, the 3D printer model, production volume and buyer application sector majorly control price levels of industrial AM parts today.

Q: Which industries are leading adopters of powder bed fusion additive manufacturing today?

A: Aerospace, medical, automotive, machine design companies focused on jigs, fixtures and tooling form over 60% of commercial customers exploring AM production applications with polymers and metals.

Q: What specialized software is required for optimally preparing and printing 3D CAD models?

A: Slicing software like Materialise Magics and SLM Build Processor auto-orient parts for best geometry and properties and adapt scanning parameters. Some printer vendors bundle proprietary software tools.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731