Rapid Solidification of Steel Droplets

Table of Contents

Overview

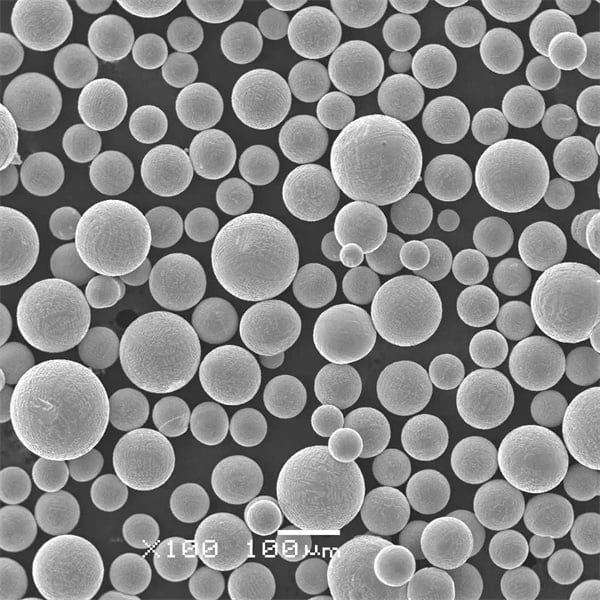

Rapid solidification is a cutting-edge technology in the field of metallurgy, particularly for the production of steel droplets. This process involves the ultra-quick cooling of molten steel to form fine microstructures that enhance the material’s properties. In this article, we’ll dive deep into the specifics of rapid solidification, the types of steel powders produced, their compositions, properties, applications, and much more. We’ll also provide comparative tables for an easy understanding of different models and their characteristics.

Understanding Rapid Solidification

Rapid solidification of steel droplets refers to the process of quickly cooling molten steel droplets to form solid steel with refined microstructures. This technique improves mechanical properties, such as strength and toughness, and enhances the material’s performance in various applications. The rapid cooling rates can reach up to millions of degrees per second, resulting in non-equilibrium microstructures that are impossible to achieve through traditional cooling methods.

Why is Rapid Solidification Important?

| Aspect | Detailed Explanation |

|---|---|

| Enhanced Mechanical Properties | Rapid solidification significantly improves the mechanical properties of steel by creating a fine-grained microstructure. This fine structure increases hardness and strength, making the material more durable and resistant to mechanical stresses. Traditional cooling methods result in larger grains, which can lead to weaknesses at grain boundaries. Rapid solidification minimizes grain size, leading to a more uniform and robust structure. This is crucial for applications requiring high strength and durability, such as in aerospace and automotive industries, where materials must withstand extreme conditions and stresses. |

| Improved Wear Resistance | Wear resistance is critical for materials used in high-stress environments. Rapid solidification enhances the wear resistance of steel by producing a more homogeneous microstructure with fewer defects and impurities. This uniformity reduces weak points where wear can begin, extending the lifespan of components. In cutting tools and machinery parts, the enhanced wear resistance provided by rapidly solidified steel results in longer-lasting tools that maintain their cutting edge and structural integrity over time. This improvement translates to cost savings and increased efficiency in industrial applications, as components require less frequent replacement and maintenance. |

| Superior Corrosion Resistance | Rapid solidification significantly enhances corrosion resistance by refining the microstructure and reducing the size of grain boundaries, thus decreasing the susceptibility of steel to corrosion. This uniform structure prevents the formation and propagation of corrosive elements within the material. In industries such as marine and chemical processing, where components are frequently exposed to harsh environments, superior corrosion resistance ensures longer service life and reduced maintenance costs. This makes rapidly solidified steel an ideal material choice for applications demanding high resistance to oxidation and chemical attack, ensuring reliability and longevity in corrosive conditions. |

| Better Machinability | The fine and uniform microstructure resulting from rapid solidification greatly improves the machinability of steel. Machinability refers to the ease with which a material can be cut, shaped, or finished. Traditional steel with larger grain structures can be challenging to machine due to uneven hardness and the presence of impurities that cause tool wear and tear. Rapidly solidified steel, with its refined structure, allows for smoother and more precise machining processes. This is particularly beneficial in manufacturing sectors where precision and efficiency are paramount, such as in the production of medical devices and high-precision instruments. The improved machinability also reduces manufacturing costs and increases the overall quality of the final products. |

| Enhanced Thermal Stability | Rapid solidification contributes to enhanced thermal stability of steel, allowing the material to retain its properties at elevated temperatures. The fine microstructure obtained through rapid cooling helps maintain the steel’s strength and hardness even when subjected to high temperatures. This is essential for applications in industries such as aerospace and power generation, where components often operate under extreme thermal conditions. Improved thermal stability ensures that steel components can perform reliably without degradation over prolonged periods of exposure to high temperatures. This characteristic is vital for the safety and efficiency of systems that rely on stable material properties in high-heat environments. |

| Reduced Segregation | Segregation refers to the non-uniform distribution of alloying elements within a material, leading to weak points and inconsistencies in the final product. Rapid solidification minimizes segregation by trapping alloying elements within the rapidly forming microstructure. This uniform distribution enhances the overall properties of the steel, making it more homogeneous and consistent. In applications such as aerospace and automotive manufacturing, where material consistency is crucial for safety and performance, the reduced segregation achieved through rapid solidification is highly beneficial. This ensures that components meet stringent quality standards and perform reliably under demanding conditions. |

| Higher Performance Alloys | Rapid solidification enables the development of higher performance alloys that are difficult or impossible to produce through conventional methods. By controlling cooling rates and solidification pathways, metallurgists can design alloys with specific properties tailored to demanding applications. These high-performance alloys often exhibit superior strength, toughness, and corrosion resistance compared to traditional alloys. This capability opens up new possibilities for innovation in material science and engineering, enabling the creation of components that meet the stringent requirements of modern technology and industrial applications. The ability to produce custom alloys with enhanced properties drives advancements across various sectors, from aerospace to biomedical engineering. |

| Amorphous and Nanocrystalline Structures | Rapid solidification can produce amorphous and nanocrystalline structures that offer unique properties not found in conventional crystalline materials. Amorphous metals, also known as metallic glasses, have a disordered atomic structure that provides excellent strength and elasticity. Nanocrystalline materials, with grain sizes in the nanometer range, exhibit exceptional hardness and wear resistance. These unique structures are valuable in advanced applications such as biomedical implants, electronic components, and high-performance coatings. The ability to create these specialized materials through rapid solidification expands the range of potential applications and enhances the performance of existing technologies, offering new solutions for high-tech industries. |

| Cost Efficiency in Production | While the initial setup for rapid solidification technology can be costly, the long-term benefits often lead to cost savings in production. Improved material properties, such as enhanced wear resistance and machinability, reduce the need for frequent replacements and maintenance. Additionally, the ability to produce high-performance alloys and specialized structures can lead to the development of more efficient and durable products. In the long run, these advantages translate to lower operational costs and increased productivity. Industries that invest in rapid solidification technology can achieve a competitive edge by producing superior products with lower lifecycle costs, leading to greater profitability and sustainability. |

| Environmental Benefits | Rapid solidification contributes to environmental sustainability by improving the durability and efficiency of steel components. The enhanced wear and corrosion resistance of rapidly solidified steel results in longer-lasting products, reducing the need for frequent replacements and, consequently, the consumption of raw materials. Moreover, the improved machinability reduces energy consumption during manufacturing processes. By extending the lifespan of products and making production more efficient, rapid solidification helps minimize waste and resource usage, contributing to more sustainable industrial practices. This is increasingly important as industries strive to meet environmental regulations and reduce their carbon footprint, ensuring that manufacturing processes are both economically and environmentally responsible. |

| Innovative Applications | The unique properties of rapidly solidified steel open up opportunities for innovative applications that were previously unattainable with traditional materials. For example, in the medical field, rapidly solidified steel can be used to create highly durable and biocompatible surgical instruments and implants. In the electronics industry, the magnetic properties of certain rapidly solidified steels can be utilized to develop advanced sensors and data storage devices. The ability to tailor the properties of steel through rapid solidification enables the development of new products and technologies that can address the evolving needs of various industries. This adaptability and innovation potential make rapid solidification a key technology for future advancements in material science and engineering. |

| Increased Product Quality | Rapid solidification leads to higher product quality by ensuring a more uniform and consistent microstructure. This uniformity reduces the occurrence of defects and imperfections in the final product, resulting in higher reliability and performance. For manufacturers, producing high-quality components is crucial for maintaining customer satisfaction and meeting industry standards. The improved quality achieved through rapid solidification enhances the reputation of manufacturers and allows them to deliver products that meet or exceed expectations. This is particularly important in sectors where product failure can have serious consequences, such as aerospace, automotive, and medical devices. The consistent quality and performance of rapidly solidified steel ensure that end products are safe, reliable, and high-performing. |

| Advanced Manufacturing Techniques | The adoption of rapid solidification technology drives the advancement of manufacturing techniques. The need to control rapid cooling rates and solidification pathways encourages the development of new equipment and processes that can handle these requirements. This technological innovation not only improves the capabilities of existing manufacturing methods but also leads to the creation of entirely new techniques. For instance, additive manufacturing, or 3D printing, can greatly benefit from rapid solidification by producing components with enhanced properties and complex geometries. The synergy between rapid solidification and advanced manufacturing techniques paves the way for cutting-edge production methods that can revolutionize various industries. These advancements ensure that manufacturers stay at the forefront of technology, enabling them to produce superior products more efficiently and cost-effectively. |

| Research and Development | Rapid solidification plays a significant role in research and development within the field of materials science. The ability to produce materials with unique microstructures and properties provides researchers with valuable insights into the fundamental behaviors of metals and alloys. This knowledge can be used to develop new theories and models that advance our understanding of material science. Additionally, the exploration of rapid solidification techniques can lead to the discovery of new materials with unprecedented properties. The ongoing research and development driven by rapid solidification contribute to the continuous improvement of materials and the expansion of technological capabilities. These efforts support the creation of next-generation materials and products, ensuring that industries can meet future challenges and demands with innovative solutions. |

| Versatility in Applications | The versatility of rapidly solidified steel makes it suitable for a wide range of applications. From high-performance aerospace components to everyday consumer goods, the enhanced properties of these materials can be tailored to meet specific requirements. This adaptability allows industries to leverage the benefits of rapid solidification across various sectors, optimizing performance and efficiency in diverse applications. Whether it’s the production of durable automotive parts or the creation of cutting-edge electronic devices, rapidly solidified steel offers a versatile solution that can address multiple challenges and improve overall product performance. This broad applicability ensures that the technology remains relevant and valuable across different |

Types of Steel Powders Produced by Rapid Solidification

Here are some specific metal powder models produced via rapid solidification, along with their descriptions:

| Model | Composition | Properties | Applications |

|---|---|---|---|

| RS-1 | Fe-Cr-Ni | High corrosion resistance, ductile | Medical implants, marine equipment |

| RS-2 | Fe-C-Mo | Excellent hardness, wear-resistant | Cutting tools, gears |

| RS-3 | Fe-Cr-Mo-V | High toughness, impact resistance | Automotive components, heavy machinery |

| RS-4 | Fe-Ni-Cr-Mo | Good thermal stability, strong | Aerospace parts, high-temperature applications |

| RS-5 | Fe-Co-Cr | Magnetic properties, durable | Magnetic sensors, electronic devices |

| RS-6 | Fe-Si-Mn | High strength, lightweight | Structural components, lightweight frameworks |

| RS-7 | Fe-Ti-Al | High heat resistance, robust | Engine parts, high-stress components |

| RS-8 | Fe-Cu-Sn | Excellent machinability, tough | Precision instruments, valves |

| RS-9 | Fe-B-Si | Amorphous structure, high strength | Transformer cores, magnetic applications |

| RS-10 | Fe-Cr-Ni-Mo | Superb corrosion and oxidation resistance | Chemical processing equipment, pipelines |

Properties and Characteristics of Rapidly Solidified Steel Powders

| Property | Description |

|---|---|

| Grain Size | Ultra-fine, typically in the nanometer to micrometer range |

| Hardness | Enhanced due to fine microstructure |

| Toughness | Improved impact resistance and durability |

| Corrosion Resistance | Superior protection against rust and chemical attack |

| Wear Resistance | High resistance to abrasion and surface degradation |

| Machinability | Easier to shape and finish due to uniform properties |

| Thermal Stability | Maintains properties at high temperatures |

| Magnetic Properties | Tailored magnetic characteristics for specific applications |

Applications of Rapid Solidification of Steel Droplets

Rapidly solidified steel powders are used in a wide array of industries due to their superior properties. Here’s a look at some of the common applications:

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Turbine blades, structural components | High strength-to-weight ratio, thermal stability |

| Automotive | Engine parts, transmission gears | Enhanced wear resistance, improved performance |

| Medical Devices | Surgical tools, implants | Corrosion resistance, biocompatibility |

| Electronics | Magnetic sensors, cores | Tailored magnetic properties, durability |

| Industrial Tools | Cutting tools, molds | Increased hardness, prolonged tool life |

| Marine | Propeller blades, marine fittings | Excellent corrosion resistance |

| Energy | Pipeline components, reactor parts | Oxidation resistance, structural integrity |

| Construction | High-strength frameworks, reinforcements | Lightweight yet strong, long-lasting |

| Consumer Goods | High-end sporting equipment, household tools | Improved performance, robustness |

| Chemical Processing | Equipment, pipelines | Superior chemical resistance, durability |

Specifications, Sizes, Grades, and Standards

| Specification | Description |

|---|---|

| Particle Size | Range from nanometers to micrometers |

| Grades | Varied based on composition and application |

| Standards | ASTM, ISO, and other industry-specific standards |

| Sizes | Customizable according to manufacturing requirements |

Suppliers and Pricing Details

Here’s a look at some of the leading suppliers of rapidly solidified steel powders and their pricing details:

| Supplier | Model | Price per Kg (USD) | Availability |

|---|---|---|---|

| PowderTech Inc. | RS-1 | $100 | In stock |

| MetalMasters | RS-2 | $150 | On order |

| Advanced Alloys | RS-3 | $120 | In stock |

| SteelInnovations | RS-4 | $130 | Limited availability |

| NanoMetals | RS-5 | $200 | On order |

| RapidMet | RS-6 | $90 | In stock |

| PrimeMaterials | RS-7 | $170 | On order |

| AlloyExperts | RS-8 | $110 | In stock |

| FineSteel | RS-9 | $160 | Limited availability |

| SuperiorMetals | RS-10 | $140 | In stock |

Comparing Pros and Cons of Rapid Solidification of Steel Droplets

| Aspect | Advantages | Limitations |

|---|---|---|

| Microstructure | Ultra-fine grains, improved properties | Complex processing technology |

| Mechanical Properties | Enhanced strength, toughness, and wear resistance | Higher production costs compared to traditional methods |

| Corrosion Resistance | Superior protection against rust and chemicals | Limited to specific applications requiring these properties |

| Manufacturing | Easier machining and finishing | Requires advanced equipment and expertise |

| Applications | Wide range of high-performance uses | May not be necessary for low-performance, cost-sensitive applications |

FAQs About Rapid Solidification of Steel Droplets

| Question | Answer |

|---|---|

| What is rapid solidification? | Rapid solidification is a process where molten steel is cooled quickly to form fine microstructures. |

| Why is rapid solidification important? | It enhances mechanical properties, wear resistance, and machinability of steel. |

| What are the key properties of rapidly solidified steel powders? | They include fine grain size, high hardness, improved toughness, and excellent corrosion resistance. |

| Where are these steel powders used? | They are used in aerospace, automotive, medical devices, electronics, and more. |

| How does rapid solidification improve material properties? | By creating ultra-fine grain structures and enhancing uniformity. |

| What are some common steel powder models? | Models include RS-1 to RS-10, each with specific compositions and applications. |

| What are the limitations of rapid solidification? | High production costs and complex technology requirements. |

| How does the process affect machinability? | It improves machinability due to the uniformity and refined microstructure of the steel. |

| Can rapid solidification be applied to other metals? | Yes, the process can be applied to various metals to enhance their properties. |

| Who are the leading suppliers of these powders? | Suppliers include PowderTech Inc., MetalMasters, Advanced Alloys, and more. |

Conclusion

Rapid solidification of steel droplets is a revolutionary technology that significantly enhances the properties of steel powders, making them ideal for high-performance applications across various industries. By understanding the different models, properties, applications, and suppliers, manufacturers can make informed decisions to leverage these advanced materials for their specific needs. Whether you’re in aerospace, automotive, or electronics, rapidly solidified steel powders offer unmatched benefits that can drive innovation and efficiency in your operations.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731