Blog

all colletions

selective electron beam melting

Imagine crafting complex metal objects layer by layer, with unparalleled precision and the ability to handle even the most challenging materials. That’s the magic of Selective Electron Beam Melting (SEBM), a revolutionary 3D printing technology that’s transforming the way we design and manufacture metal components. What is selective electron beam

Martensitic Stainless Steel

Martensitic stainless steel: the name might sound like something out of a superhero movie, but this wonder material packs a serious punch in the real world. Imagine a metal that’s not only resistant to rust and corrosion but can also be hardened to incredible strength – that’s the magic of

plasam atomization

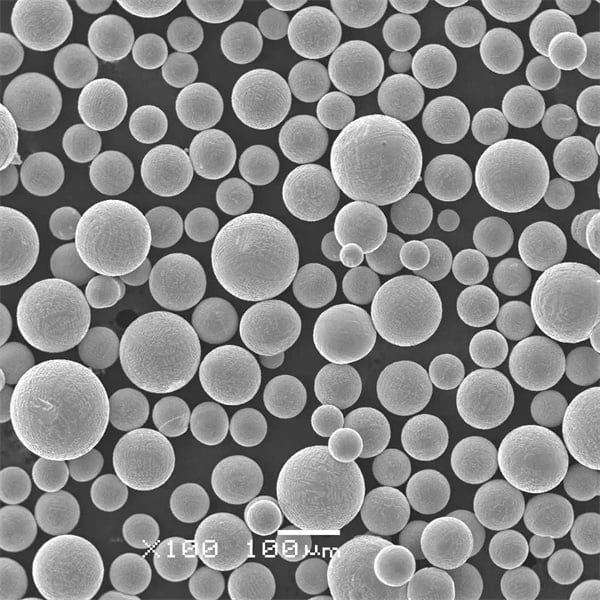

Imagine a sculptor, not wielding a chisel and hammer, but wielding a high-tech torch that breaks down molten metal into perfectly spherical particles. That’s the essence of plasam atomization, a transformative technology that’s revolutionizing the way we create advanced materials. What is plasam atomization? Plasma atomization utilizes the intense heat

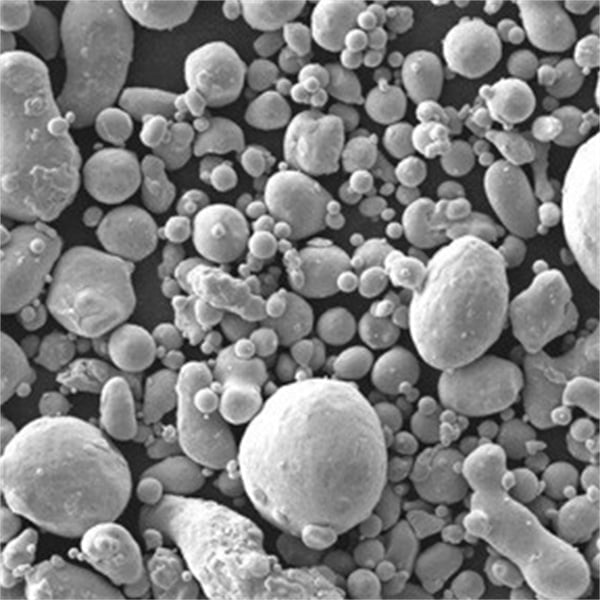

The Atomization Process

Imagine a sculptor, meticulously chipping away at a massive block of stone, transforming it into a delicate figurine. The atomization process operates on a similar principle, but instead of chisels and stone, it utilizes high-powered jets to break down molten metals or liquids into minuscule, highly-functional particles. This article delves

High Frequency Induction Melting

Imagine a furnace that heats metal not with flames or burning fuel, but with the invisible power of electricity. This isn’t science fiction; it’s the reality of high frequency induction melting, a revolutionary technology transforming the way we melt metals, particularly metal powders. What is High Frequency Induction Melting? High

Titanium Wire

Imagine a material that’s incredibly strong, yet remarkably lightweight. A metal that defies corrosion and tolerates extreme temperatures. That’s the magic of titanium wire. This seemingly unassuming strand packs a powerful punch, finding its way into countless applications across various industries. But before we delve into the world of titanium

selective electron beam melting

Imagine crafting complex metal objects layer by layer, with unparalleled precision and the ability to handle even the most challenging materials. That’s the magic of

Martensitic Stainless Steel

Martensitic stainless steel: the name might sound like something out of a superhero movie, but this wonder material packs a serious punch in the real

plasam atomization

Imagine a sculptor, not wielding a chisel and hammer, but wielding a high-tech torch that breaks down molten metal into perfectly spherical particles. That’s the

The Atomization Process

Imagine a sculptor, meticulously chipping away at a massive block of stone, transforming it into a delicate figurine. The atomization process operates on a similar

High Frequency Induction Melting

Imagine a furnace that heats metal not with flames or burning fuel, but with the invisible power of electricity. This isn’t science fiction; it’s the

Titanium Wire

Imagine a material that’s incredibly strong, yet remarkably lightweight. A metal that defies corrosion and tolerates extreme temperatures. That’s the magic of titanium wire. This

Our Product

HOT SALE PRODUCT

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731