Detailed Analysis of EBM Process Flow

Table of Contents

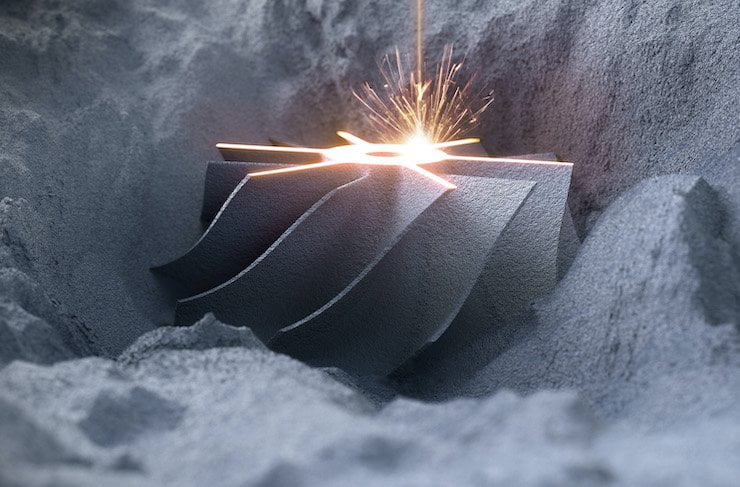

Electron Beam Melting (EBM) is a revolutionary 3D printing technology that’s rapidly transforming the manufacturing landscape. Imagine building complex metal parts layer by layer using a focused electron beam – that’s the essence of EBM! But have you ever wondered what goes on behind the scenes of this high-tech process? Buckle up, because we’re about to embark on a detailed analysis of the EBM process flow, dissecting each stage to unveil its magic.

Preparation Work for EBM Process Flow

Before the electron beam starts its dance, some crucial groundwork needs to be laid. Here’s what sets the stage:

- CAD Design: Everything starts with a digital blueprint. Your 3D model, meticulously crafted using CAD software, acts as the blueprint for the EBM machine to follow.

- Metal Powder Selection: The heart of EBM lies in the metal powder used. These fine, metallic particles (typically ranging from 20 to 100 microns) come in various flavors, each with unique properties. We’ll delve deeper into the fascinating world of metal powders in a moment.

- Machine Setup and Calibration: The EBM machine itself is a marvel of engineering. It houses a high-powered electron gun, a vacuum chamber to maintain a pristine environment, and a build platform that meticulously lowers with each layer. Calibration ensures the electron beam strikes the powder bed with pinpoint accuracy, a crucial step for achieving dimensional precision.

Metal Powder Selection: A Powder Powerhouse

As mentioned earlier, metal powder is the lifeblood of EBM. Here’s a closer look at some of the most popular options, along with their key characteristics:

| Metal Powder | Composition | Properties | Applications |

|---|---|---|---|

| Ti-6Al-4V (Titanium Alloy) | 6% Aluminum, 4% Vanadium, Titanium Balance | High strength-to-weight ratio, excellent biocompatibility | Aerospace components, biomedical implants, prosthetics |

| Stainless Steel 316L | Chromium, Nickel, Molybdenum, Iron Balance | Corrosion resistance, good mechanical properties | Medical devices, chemical processing equipment, marine components |

| Inconel 625 (Superalloy) | Nickel, Chromium, Molybdenum, Columbium, Iron Balance | High-temperature strength, oxidation resistance | Gas turbine components, rocket engine parts, heat exchangers |

| CoCrMo (Cobalt-Chromium Molybdenum Alloy) | Cobalt, Chromium, Molybdenum | Biocompatible, wear-resistant | Joint replacements, dental implants |

| Aluminum Alloys (AlSi10Mg, etc.) | Aluminum with Silicon, Magnesium | Lightweight, good strength | Automotive components, aerospace structures, heat sinks |

| Copper | Pure Copper | High thermal conductivity, good electrical conductivity | Heat exchangers, electrical components, waveguides |

| Tungsten | Pure Tungsten | High melting point, high density | Moulding tools, electrodes, ballistic applications |

| Maraging Steel | Nickel, Molybdenum, Titanium, Iron Balance | High strength, good ductility | Aerospace components, firearms parts, tooling |

| Nickel Superalloys (Inconel 718, etc.) | Complex compositions with Nickel, Chromium, Molybdenum | Exceptional high-temperature performance | Turbine blades, rocket engine parts, heat exchangers |

| Titanium Alloys (CP Ti, etc.) | Commercially Pure Titanium | Excellent biocompatibility, good corrosion resistance | Medical implants, dental applications, chemical processing equipment |

This list is just a glimpse into the vast array of metal powders available for EBM. The choice of powder depends on the desired properties of the final part, such as strength, weight, corrosion resistance, biocompatibility, and thermal conductivity.

Electron Beam Scanning of EBM Process Flow

Now comes the magic! The electron gun within the EBM machine hums to life, generating a highly focused beam of electrons. This beam acts like a virtual paintbrush, selectively melting the metal powder according to the pre-programmed CAD design. Here’s a breakdown of the scanning process:

- Deflection System: The electron beam isn’t a rigid line. A sophisticated deflection system controls its movement, directing it across the powder bed to precisely define the desired pattern for each layer.

- Scan Strategies: There are various scan strategies employed in EBM, each with its advantages. Common approaches include raster scanning, vector scanning, and island scanning. The choice of strategy depends on factors like part geometry, surface finish requirements, and thermal management.

- Beam Power Control: The power of the electron beam plays a crucial role. Higher power results in deeper melting and potentially faster build times. However, meticulous control is essential to prevent overheating and distortion of the part. Imagine balancing a searing hot paintbrush on a bed of metal powder – that’s the delicate dance of EBM!

-

Ti45Nb Powder for Additive Manufacturing

Ti45Nb Powder for Additive Manufacturing -

TiNb Alloy Powder

TiNb Alloy Powder -

TiNbZrSn Alloy Powder

TiNbZrSn Alloy Powder -

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing -

CPTi Powder

CPTi Powder -

TC18 Powder : Unlocking the Power of Titanium Carbide

TC18 Powder : Unlocking the Power of Titanium Carbide -

TC11 Powder : A Comprehensive Guide

TC11 Powder : A Comprehensive Guide -

TC4 ELI Powder

TC4 ELI Powder -

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

Layer by Layer Manufacturing of EBM Process Flow

EBM builds parts in a truly additive fashion, one layer at a time. Here’s how this layer-by-layer magic unfolds:

- Recoat Blade: After each layer is scanned by the electron beam, a recoat blade meticulously spreads a fresh layer of metal powder across the build platform. This ensures a continuous supply of material for the next layer to be melted.

- Thermal Management: EBM involves localized melting, but heat doesn’t stay confined. The machine employs various techniques, like preheating the build platform and using support structures, to manage thermal gradients and prevent warping or cracking in the part.

- Layer Thickness: The thickness of each layer in EBM can vary depending on the desired resolution and build time. Typical layer thicknesses range from 30 to 100 microns, offering a balance between detail and efficiency.

Imagine building a complex structure brick by brick, but instead of bricks, you’re using layers of melted metal – that’s the essence of EBM’s layer-by-layer manufacturing process. This approach allows for the creation of intricate geometries and internal features that would be impossible with traditional subtractive techniques like machining.

Post Processing of EBM Process Flow

The journey doesn’t end after the final layer is melted. Here’s what follows:

- Stress Relief: EBM parts can experience residual stress due to the thermal cycles involved in the process. Stress relief annealing helps to alleviate these stresses, improving the part’s dimensional stability and mechanical properties.

- Support Structure Removal: Similar to removing scaffolding from a building, support structures used during the EBM process need to be removed. This can be done through various methods, such as wire EDM or mechanical cutting.

- Surface Finishing: As-built EBM surfaces can be slightly rough due to the nature of the process. Post-processing techniques like machining, polishing, or blasting can be used to achieve the desired surface finish.

Think of post-processing as the final touches on your masterpiece. These steps ensure the EBM part meets the required dimensional accuracy, mechanical properties, and surface aesthetics.

Advantages and Limitations of EBM

EBM boasts several compelling advantages:

- Design Freedom: EBM excels at creating complex geometries, including internal features and lattice structures, that are difficult or impossible with traditional methods.

- High-Performance Materials: The process is compatible with a wide range of high-performance metal powders, enabling the creation of parts with exceptional strength, heat resistance, and biocompatibility.

- Near-Net-Shape Manufacturing: EBM minimizes material waste compared to subtractive techniques, offering a more sustainable and cost-effective approach for certain applications.

However, EBM also has limitations to consider:

- Build Time: EBM can be a slower process compared to some other 3D printing methods, especially for larger parts.

- Surface Roughness: As-built EBM surfaces can be slightly rough, requiring additional post-processing for some applications.

- Cost: EBM machines and metal powders can be expensive, making the process more suitable for high-value parts or applications where its unique capabilities are essential.

EBM is a powerful tool, but like any tool, it’s best suited for specific jobs. Understanding its strengths and weaknesses allows you to make informed decisions about its suitability for your project.

FAQ

Here are some frequently asked questions about the EBM process flow, answered in a clear and concise format:

| Question | Answer |

|---|---|

| What are the benefits of EBM over other 3D printing methods? | EBM offers superior design freedom, enables the use of high-performance metal powders, and minimizes material waste compared to some subtractive techniques. |

| What are some limitations of EBM? | EBM can be slower than other methods, may require post-processing for surface finish, and can be more expensive due to machine and material costs. |

| What types of metal powders can be used in EBM? | A wide range of metal powders can be used, including titanium alloys, stainless steel, superalloys, cobalt-chrome, aluminum alloys, and more. |

| What are some applications of EBM? | EBM is used in various industries, including aerospace, biomedical, automotive, and energy, for creating high-performance metal parts. |

| How does the electron beam scan the powder bed? | A sophisticated deflection system controls the electron beam, directing it across the powder bed to define the desired pattern for each layer. |

Conclusion

Electron Beam Melting (EBM) is more than just a 3D printing technology; it’s a gateway to a world of possibilities. By meticulously melting metal powder layer by layer, EBM unlocks the creation of complex, high-performance parts that were once thought impossible. From intricate aerospace components to life-saving biomedical implants, EBM is pushing the boundaries of design and manufacturing.

As with any complex technology, understanding the EBM process flow is crucial. We’ve delved into each stage, from the meticulous preparation work to the layer-by-layer magic and the finishing touches of post-processing. This knowledge empowers you to make informed decisions about whether EBM is the right tool for your project.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731