High Thermal Conductivity Alloys

Table of Contents

Overview of High Thermal Conductivity Alloys

High thermal conductivity alloys are a class of materials designed to efficiently transfer heat. These alloys are critical in various industries, including electronics, automotive, aerospace, and power generation. Their ability to dissipate heat quickly and effectively ensures the performance and longevity of components and systems.

Thermal conductivity measures a material’s ability to conduct heat. High thermal conductivity alloys are engineered to maximize this property, making them indispensable in applications where efficient heat dissipation is crucial.

Why are these alloys important? Imagine your computer overheating because it can’t get rid of the heat generated by its processor. High thermal conductivity alloys solve such problems by quickly moving heat away from sensitive components, preventing damage and maintaining optimal performance.

Types of High Thermal Conductivity Alloys

1. Copper Alloys

Copper is renowned for its excellent thermal conductivity. When alloyed with other metals, it can offer enhanced mechanical properties while maintaining high thermal conductivity.

Types and Characteristics:

| Alloy Type | Composition | Properties | Characteristics |

|---|---|---|---|

| C11000 | 99.9% Copper | High thermal and electrical conductivity | Soft, ductile, excellent for electrical applications |

| C17200 | Copper-Beryllium | High strength, good thermal conductivity | Resistant to fatigue, suitable for springs and connectors |

| C18200 | Copper-Chromium | High hardness, good thermal conductivity | Used in welding electrodes, resistant to wear and deformation |

| C18150 | Copper-Chromium-Zirconium | Good balance of strength and conductivity | Ideal for resistance welding, high durability |

2. Aluminum Alloys

Aluminum is another metal with good thermal conductivity, often used when weight reduction is essential.

Types and Characteristics:

| Alloy Type | Composition | Properties | Characteristics |

|---|---|---|---|

| 1050 | 99.5% Aluminum | Excellent thermal conductivity, soft | Used in heat exchangers, good formability |

| 6061 | Al-Mg-Si alloy | Good thermal conductivity, strong, weldable | Common in aerospace and automotive applications |

| 7075 | Al-Zn-Mg-Cu alloy | High strength, moderate thermal conductivity | Suitable for high-stress applications |

3. Silver Alloys

Silver boasts the highest thermal conductivity among metals, but its use is limited due to cost.

Types and Characteristics:

| Alloy Type | Composition | Properties | Characteristics |

|---|---|---|---|

| Ag-Cu | Silver-Copper | Extremely high thermal conductivity | Used in specialized electronics and thermal management systems |

| Ag-Pd | Silver-Palladium | High thermal conductivity, tarnish-resistant | Suitable for high-reliability electrical contacts |

4. Gold Alloys

Gold alloys are used in applications requiring high thermal conductivity and excellent corrosion resistance.

Types and Characteristics:

| Alloy Type | Composition | Properties | Characteristics |

|---|---|---|---|

| Au-Cu | Gold-Copper | High thermal conductivity, corrosion-resistant | Used in high-end electronics, aerospace applications |

| Au-Ni | Gold-Nickel | Good thermal conductivity, improved strength | Ideal for connectors and contacts in harsh environments |

5. Diamond Composites

Diamond composites offer unparalleled thermal conductivity, though they are costly and challenging to produce.

Types and Characteristics:

| Alloy Type | Composition | Properties | Characteristics |

|---|---|---|---|

| Cu-Diamond | Copper-Diamond | Exceptional thermal conductivity | Used in high-power laser diodes and semiconductor devices |

| Al-Diamond | Aluminum-Diamond | High thermal conductivity, lightweight | Ideal for aerospace applications requiring heat dissipation |

Applications of High Thermal Conductivity Alloys

High thermal conductivity alloys are employed across various sectors to manage heat efficiently. Let’s explore some key applications:

| Application | Alloys Used | Benefits |

|---|---|---|

| Electronics | C11000, 1050, Ag-Cu | Efficient heat dissipation, preventing overheating |

| Automotive | 6061, 7075, Cu-Diamond | Enhances engine performance, prolongs component life |

| Aerospace | Al-Diamond, 7075, Au-Cu | Reduces weight while managing heat in high-stress environments |

| Power Generation | C18150, C18200, Al-Diamond | Improves efficiency of turbines and generators |

| Medical Devices | Ag-Pd, Au-Ni | Ensures reliability and longevity of sensitive instruments |

Specifications and Standards for High Thermal Conductivity Alloys

Understanding the specifications and standards is crucial when selecting the right alloy for an application.

| Alloy Type | Standard | Thermal Conductivity (W/m·K) | Typical Uses |

|---|---|---|---|

| C11000 | ASTM B152 | 385 | Electrical applications, heat exchangers |

| 6061 | ASTM B221 | 167 | Structural components, heat sinks |

| 7075 | ASTM B209 | 130 | Aerospace, military applications |

| Ag-Cu | ASTM B780 | 429 | High-performance electronics |

| Cu-Diamond | Custom | >1000 | High-power semiconductor devices |

Suppliers and Pricing Details for High Thermal Conductivity Alloys

Finding reliable suppliers and understanding the pricing of these specialized materials can be challenging. Here’s a snapshot of some suppliers and price ranges:

| Supplier | Alloy Types Offered | Price Range (per kg) |

|---|---|---|

| Materion | Cu-Be, Cu-Cr-Zr | $50 – $150 |

| Kaiser Aluminum | 1050, 6061, 7075 | $5 – $50 |

| Ames Goldsmith | Ag-Cu, Ag-Pd | $500 – $2000 |

| Plansee | Cu-Diamond, Al-Diamond | Custom pricing |

Advantages and Disadvantages of High Thermal Conductivity Alloys

When choosing high thermal conductivity alloys, it’s important to weigh their benefits and limitations:

| Advantage | Description |

|---|---|

| High Efficiency | Excellent heat dissipation capabilities |

| Durability | Often combined with high strength and corrosion resistance |

| Versatility | Suitable for various applications across industries |

| Disadvantage | Description |

|---|---|

| Cost | High-performance alloys can be expensive |

| Complexity | Some alloys require specialized manufacturing processes |

FAQ

| Question | Answer |

|---|---|

| What is thermal conductivity? | It is a measure of a material’s ability to conduct heat. |

| Why are high thermal conductivity alloys important? | They efficiently transfer heat, preventing overheating in devices. |

| Which metals have the highest thermal conductivity? | Silver, copper, and gold are among the top metals with high thermal conductivity. |

| Can aluminum alloys be used for high thermal conductivity applications? | Yes, especially in situations where weight reduction is also needed. |

| What industries benefit from these alloys? | Electronics, automotive, aerospace, power generation, and medical sectors. |

Conclusion

High thermal conductivity alloys play a crucial role in modern technology, ensuring that heat is effectively managed across various applications. From the highly conductive copper alloys to the advanced diamond composites, these materials offer unique properties that cater to the needs of different industries. Whether you’re designing a cutting-edge electronic device or a high-performance automotive engine, selecting the right alloy can make all the difference in performance and reliability.

Understanding the types, properties, applications, and specifications of these alloys empowers engineers and designers to make informed decisions, ultimately leading to better and more efficient products. As technology continues to advance, the demand for high thermal conductivity alloys will only grow, underscoring their importance in our increasingly thermal-centric world.

Share On

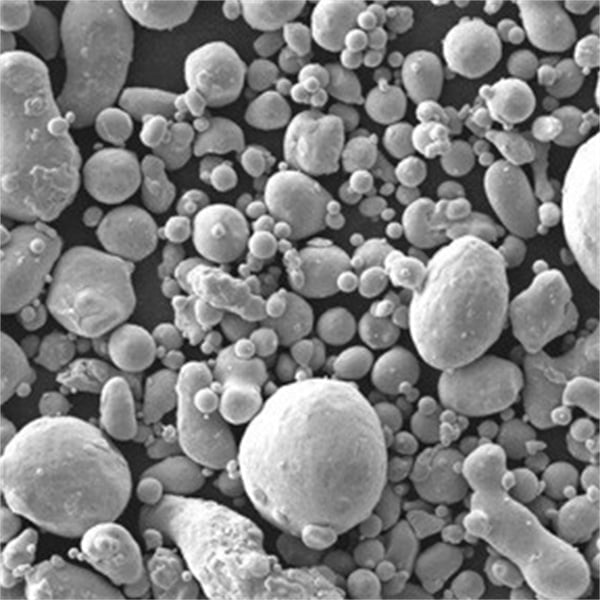

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731