Metal 3D Printing Service

Get quality metal 3D-printed prototypes and production parts.

Why work with Metal 3DP

At Metal3DP, our mission is to simplify the complexities of metal part production. From collaborating with our skilled Design & Engineering Team to leveraging our state-of-the-art Metal Competence Center in Bremen, we enable you to harness the agility and efficiency of metal 3D printing over traditional methods. Whether you require prototypes or large-scale production runs, Metal3DP is your trusted partner throughout the entire process.

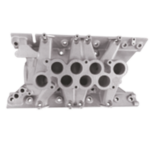

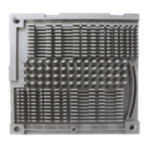

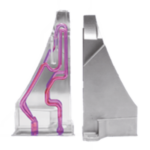

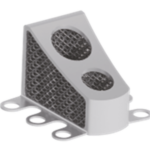

Metal 3D printing technology is commonly used for:

- Prototyping in production-grade materials

- Complex geometries

- Functional, end-use parts

- Reducing metal components in an assembly

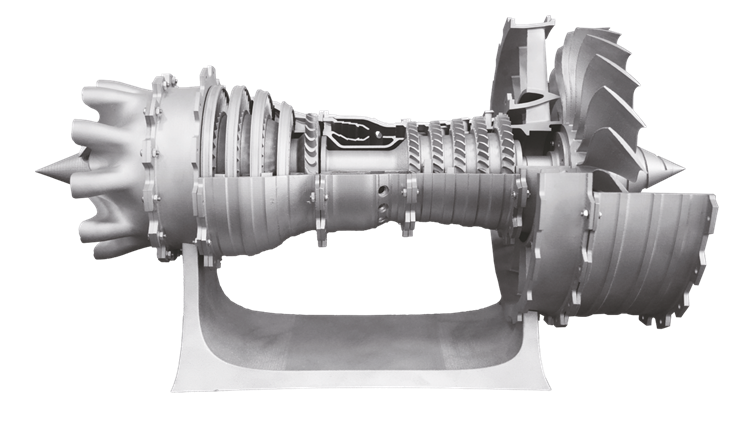

aerospace

Industrial Molds

3C electronics

shipbuilding

biomedical

automobile

oil and nuclear

scientific

Metal 3D Printing Capabilities

At Metal3DP, we provide essential guidelines for metal 3D printing that focus on optimizing part manufacturability, elevating cosmetic appearance, and minimizing production time.

Max Dimensions

| US | Metric | |

| Normal Resolution | 9.6 in. x 9.6 in. x 13.0 in. |

245mm x 245mm x 330mm

|

| Normal Resolution (X Line*) | 31.5 in. x 15.7 in. x 19.7 in. |

400mm x 800mm x 500mm

|

| High Resolution | 3.5 in. x 3.5 in. x 2.7 in. Al: 3.8 in. x 3.8 in. x 3.7 in. |

88mm x 88mm x 70mm

Al: 98mm x 98mm x 94mm

|

| *At this time, Inconel 718 and Aluminum are the only materials available on our large format, X Line machine | ||

Layer Thickness

| US | Metric | |

| Normal Resolution | 0.0012 in. | 30 microns |

| Normal Resolution (X Line*) | Inconel: 0.00236 in. Aluminum: 0.00157 in. |

Inconel: 60 microns

Aluminum: 40 microns

|

| High Resolution | 0.00079 in. | 20 microns |

| *At this time, Inconel 718 and Aluminum are the only materials available on our large format, X Line machine | ||

Minimum Feature Size

| US | Metric | |

| Normal Resolution | 0.015 in (0.030 in. for Aluminum) |

0.381mm

(0.762mm for Aluminum)

|

| Normal Resolution (X Line*) | 0.015 in. (0.030 in. for Aluminum) |

0.381mm

(0.762mm for Aluminum)

|

| High Resolution | 0.006 in. Aluminum: 0.015 in. |

0.153mm

Aluminum: 0.381mm

|

| *At this time, Inconel 718 and Aluminum are the only materials available on our large format, X Line machine | ||

Tolerances

For well-designed parts, tolerances of +0.003 in. (0.076mm) plus 0.1% of nominal length can typically be achieved. Note that tolerances may change depending on part geometry.

Metal 3D Printing Material Options

Here are the metal alloys available for 3D printing through Metal3DP. We offer a range of heat treatments tailored to each material’s specifications.

Stainless Steel (17-4 PH)

Consider Stainless Steel 17-4 PH for your stainless steel needs at Metal3DP. Renowned for its exceptional hardness and corrosion resistance, this precipitation hardened stainless steel offers superior tensile and yield strength compared to 316L. However, it’s important to note that it exhibits less elongation at break. Final parts crafted from 17-4 PH undergo vacuum solution heat treatment and H900 aging.

Primary Advantages:

- Heat treated for optimal hardness and strength

- Exceptional corrosion resistance

Stainless Steel (316L)

Opt for Stainless Steel 316L at Metal3DP for the fabrication of acid and corrosion-resistant components. Chosen when flexibility is paramount, 316L offers superior malleability compared to 17-4 PH. Parts printed in 316L undergo stress relief application for enhanced performance.

Primary Advantages:

- Exceptional resistance to acid and corrosion

- High ductility

Aluminum (AlSi10Mg)

Opt for Aluminum (AlSi10Mg) at Metal3DP, akin to a 3000 series alloy commonly utilized in casting and die casting. This material boasts a commendable strength-to-weight ratio, coupled with high temperature and corrosion resistance. Additionally, AlSi10Mg showcases excellent fatigue, creep, and rupture strength, alongside notable thermal and electrical conductivity properties. Final parts crafted in AlSi10Mg undergo stress relief application for optimal performance.

Primary Advantages:

- Remarkable stiffness and strength in proportion to weight

- Superior thermal and electrical conductivity

Inconel 718

Opt for Inconel at Metal3DP, a high-strength, corrosion-resistant nickel-chromium superalloy tailored for components enduring extreme temperatures and mechanical loads. Parts printed in Inconel 718 undergo stress relief application, with the option for solution and aging per AMS 5663 to boost tensile strength and hardness.

Primary Advantages:

- Exceptional resistance to oxidation and corrosion

- Outstanding tensile, fatigue, creep, and rupture strength

Cobalt Chrome (Co28Cr6Mo)

Metal3DP offers Cobalt Chrome (CoCr28Mo6 Powder), a superalloy celebrated for its exceptional strength-to-weight ratio and a myriad of benefits. With outstanding tensile and creep performance, this material ensures reliability even under extreme conditions. Moreover, its corrosion resistance adds to its appeal, making it an ideal choice for demanding applications.

Primary Advantages:

- Exceptional tensile and creep performance

- Superior corrosion resistance

Titanium (Ti6Al4V)

Opt for Titanium (Ti6Al4V) at Metal3DP, a versatile alloy widely recognized for its exceptional mechanical properties. Compared to Ti grade 23 annealed, Ti6Al4V offers comparable tensile strength, elongation, and hardness, making it a reliable choice for various applications. Parts crafted in Ti6Al4V undergo vacuum stress relief application for optimal performance.

Primary Advantages:

- Superior stiffness and strength in proportion to weight

- Excellent resistance to high temperatures and corrosion

| Materials | Resolution | Condition | Ultimate Tensile Strength (ksi) |

Yield Stress (ksi) |

Elongation (%) |

Hardness |

|---|---|---|---|---|---|---|

| Stainless Steel (17-4 PH) |

20 μm | Solution & Aged (H900) | 199 | 178 | 10 | 42 HRC |

| 30 μm | Solution & Aged (H900) | 198 | 179 | 13 | 42 HRC | |

| Stainless Steel (316L) |

20 μm | Stress Relieved | 82 | 56 | 78 | 90 HRB |

| 30 μm | Stress Relieved | 85 | 55 | 75 | 88 HRB | |

| Aluminum (AlSi10Mg) |

20 μm | Stress Relieved | 39 | 26 | 15 | 42 HRB |

| 30 μm | Stress Relieved | 50 | 33 | 8 | 59 HRB | |

| 40 μm | Stress Relieved | 43 | 27 | 10 | 50 HRB | |

| Cobalt Chrome (Co28Cr6Mo) |

20 μm | As Built | 182 | 112 | 17 | 39 HRC |

| 30 μm | As Built | 176 | 119 | 14 | 38 HRC | |

| Inconel 718 | 20 μm | Stress Relieved | 143 | 98 | 36 | 33 HRC |

| 30 μm | Stress Relieved | 144 | 91 | 39 | 30 HRC | |

| 30 μm | Solution & Aged per AMS 5663 | 208 | 175 | 18 | 46 HRC | |

| 60 μm | Stress Relieved | 139 | 83 | 40 | 27 HRC | |

| 60 μm | Solution & Aged per AMS 5663 | 201 | 174 | 19 | 45 HRC | |

| Titanium (Ti6Al4V) |

20 μm | Stress Relieved | 153 | 138 | 15 | 35 HRC |

| 30 μm | Stress Relieved | 144 | 124 | 18 | 33 HRC |

20 μm = high resolution (HR)

30, 40, and 60 μm = normal resolution (NR)

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Post-Processing Capabilities for Metal 3D-Printed Parts

Surface Finishing

- 3- and 5-axis milling

- Turning

- Polish (Mirror or Brushed)

- Passivation

- Wire EDM

- Tapping and reaming

Heat Treatments

- Stress relief

- NADCAP heat treatment

- Hot isostatic pressing (HIP)

- Solution annealing

- Aging

Mechanical Testing

- Tensile

- Rockwell Hardness

Powder Analysis & Material

- Traceability

- Chemistry

- Particle size and distribution analysis

Partner with Metal3DP

Online 3D Printing Services

Gain direct 24/7 access to cutting-edge technologies and materials. Receive instant quotes, benefit from short lead-times, and enjoy easy checkout to bring your designs to life.

Manufacturing Services

Collaborate with our experts to innovate and accelerate manufacturing. Utilize our full spectrum of in-house technologies suitable for diverse industries and applications.

Versatile Applicability

Transform your product development cycle and expedite time-to-market. Receive unbiased advice and dedicated support from teams committed to your success.

Consultancy

Work with our seasoned experts to translate business challenges into opportunities. Explore potential applications and strategies tailored to meet your specific needs and objectives.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731