Nickel Metal Powder

Table of Contents

Overview

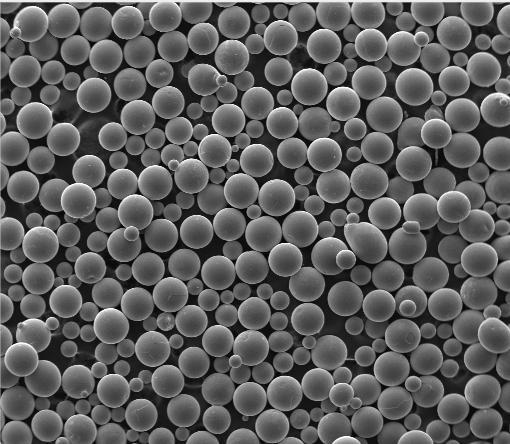

Nickel metal powder is a fine granular form of nickel made by atomizing molten nickel into very small droplets which solidify into a powder form. It has unique properties that make it useful for applications like additive manufacturing, surface coating, electronics, welding products, and more.

Key details about nickel metal powder:

- Composition – Pure nickel or nickel alloys with metals like iron, copper, etc.

- Particle shape – Spherical, irregular, dendritic, or mixed morphology

- Size range – From 10 nanometers to 150 microns typically

- Purity – From 99% up to 99.99% pure nickel

- Production methods – Atomization, carbonyl decomposition, electrolysis, milling

- Key properties – High purity, good conductivity and magnetism, excellent corrosion resistance, ability to form alloys

- Main applications – 3D printing powder, thermal spray coatings, battery electrodes, diamond tools, electronics

Types of Nickel Metal Powder

| Type | Composition | Characteristics | Uses |

|---|---|---|---|

| Pure nickel | 99-99.9% Ni | High purity, good conductivity/magnetism, alloyability | Electronics, coatings, welding, 3D printing |

| Nickel alloys | Ni + Fe, Cu, Cr, etc. | Enhanced properties like strength, wear resistance | Surface engineering, high-temp applications |

| Carbonyl nickel | >99.9% Ni | Ultra high purity, spheroidal particles | Electronics, MLCCs, welding |

| Nanosized nickel | <100 nm particles | Very large surface area, high reactivity | Catalysts, batteries, sensors |

Properties of Nickel Metal Powder

| Property | Details | Significance |

|---|---|---|

| Composition | Pure nickel or nickel alloys | Determines properties like strength, corrosion resistance, curie temperature |

| Particle morphology | Spherical, irregular, dendritic, mixed | Affects flowability, packing density, sintering |

| Particle size | 10 nm to 150 μm typically | Suitability for application method, determines properties |

| Apparent density | Around 1-4 g/cc | Impacts compression and handling |

| Tap density | Up to 65% of solid density | Indicates packing efficiency |

| Purity | Up to 99.999% Ni content | Purity affects conductivity, permeability, oxidation resistance |

| Specific surface area | 0.1 – 10 m2/g | Determines reactivity, sintering rates |

Applications of Nickel Metal Powder

Nickel powder is used in a wide range of industries due to its unique properties like high permeability, corrosion resistance, alloyability, and catalytic activity.

| Application | Details |

|---|---|

| Additive manufacturing | Used in powder bed fusion and binder jetting 3D printers to make Ni parts |

| Surface coatings | Applied via thermal spray or electro/electroless plating for wear/corrosion protection |

| Welding products | Used to make hardfacing alloys and welding wires/rods |

| Electronics | Used in conductors, resistors, capacitors, magnetic cores of electronics |

| Batteries | Added to battery electrodes and interconnects |

| Diamond tools | Used as binder material for making diamond abrasive tools |

| Catalysts | Nickel catalysts used for hydrogenation, reforming, organic reactions |

-

Ti45Nb Powder for Additive Manufacturing

Ti45Nb Powder for Additive Manufacturing -

TiNb Alloy Powder

TiNb Alloy Powder -

TiNbZrSn Alloy Powder

TiNbZrSn Alloy Powder -

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing -

CPTi Powder

CPTi Powder -

TC18 Powder : Unlocking the Power of Titanium Carbide

TC18 Powder : Unlocking the Power of Titanium Carbide -

TC11 Powder : A Comprehensive Guide

TC11 Powder : A Comprehensive Guide -

TC4 ELI Powder

TC4 ELI Powder -

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

Nickel Metal Powder Specifications

Nickel powder is available in various size ranges, purities, morphologies, and can be customized to meet application requirements in terms of composition, flowability, packing density, reactivity and more.

| Parameter | Range | Grades/Standards |

|---|---|---|

| Particle size | 10 nm to 150 μm | Ultrafine, fine, coarse grades based on mesh sizes |

| Purity | 99 to 99.999% Ni | Std. commercial, high purity, ultra high purity grades |

| Apparent density | 1 to 4 g/cc typically | Customized based on tap density |

| Specific surface area | 0.1 to 10 m2/g | Nano, submicron, micron scale surface areas |

| Alloy composition | Ni + Fe, Cu, Co, Cr, Mo etc. | Custom alloys based on application |

| Porosity | 20 to 90% | Customized porosity for filters, electrodes |

International standards for nickel powder include:

- ASTM B162 – Standard for Nickel Plate, Sheet, and Strip

- ASTM B783 – Standard Specification for Material and Manufacture for Corrosion-Resistant Nickel Products

- ISO 2401 – Nickel, nickel alloys and nickel-plated materials – Vickers hardness test

Suppliers and Pricing

Nickel powder is produced by companies like Vale, Jien Nickel, Vale Metech, and is sold directly or through metal powder distributors. Pricing depends on size, purity, morphology and purchase quantity.

| Supplier | Description | Indicative Pricing |

|---|---|---|

| Vale | Leading producer of high purity nickel metal powders | $50/kg for 99.7%, $150/kg for 99.99% purity |

| Jien Nickel | Major Chinese nickel and ferroalloy powder producer | $30-100/kg for 98-99.9% nickel powder |

| Vale Metech | Key producer of spherical & alloy nickel powders | $250/kg for <10 μm, 99.8% purity powder |

| Metal powder suppliers | Distributors like Alfa Aesar, ESPI sell various Ni powder grades | $100-1000/kg for 99 to 99.99% Ni powders |

Pricing varies from $30/kg for commercial grade powder up to $1000/kg for high purity nano-scale powder. Customization for particle shape, size, density incurs additional charges.

Comparing Nickel Metal Powder Types

| Parameter | Pure Ni Powder | Carbonyl Ni Powder | Nano Ni Powder | Alloy Ni Powder |

|---|---|---|---|---|

| Particle morphology | Irregular, dendritic | Spherical | Spherical | Mixed, irregular |

| Typical size range | 1-150 μm | 1-15 μm | <100 nm | 5-100 μm |

| Purity | 99-99.9% | >99.9% | 99.7-99.9% | 92-99% |

| Cost | Low | High | Very high | Medium |

| Properties | Good conductivity/magnetism | High purity | Very high reactivity | Enhanced strength |

| Ease of handling | Average | Very good | Difficult | Good |

| Main applications | Coatings, welding, 3D printing | MLCCs, electronics | Catalysts, batteries | Wear parts, high temperature |

Advantages and Limitations of Nickel Metal Powder

| Advantages | Limitations |

|---|---|

| Excellent corrosion resistance | Expensive compared to iron or copper powder |

| High purity grades available | Prone to oxidation at high temperatures |

| Alloyable with diverse elements | Lower compressibility and green strength vs. iron powder |

| High permeability and thermal conductivity | Sensitive to traces of sulfur or carbon impurities |

| Good catalytic activity | More difficult to atomize vs. copper or aluminum |

| Non-toxic compared to cobalt or nickel |

Nickel powder offers significant benefits but also has some limitations primarily related to cost and chemical reactivity. Proper handling and storage is important to preserve purity and prevent oxygen/moisture pickup.

FAQs

Q. What is the main use of nickel powder?

A. The primary use of nickel powder is in fabrication of corrosion and wear-resistant parts via powder metallurgy technique of metal 3D printing. Other key uses are production of surface coatings, nickel steel alloys, battery electrodes, welding consumables, etc.

Q. Is nickel powder flammable or explosive?

A. Nickel powder is generally non-flammable. But fine powders can form explosive dust-air mixtures and hence precautions are necessary for safe handling and prevention of dust explosions.

Q. What process is used to make nickel metal powder?

A. The main production method is atomization where purified molten nickel is broken into fine droplets using water or gas jets. The droplets solidify into powder. Other methods like carbonyl decomposition, electrolysis, milling are also used.

Q. What is the difference between nickel metal powder and nickel oxide powder?

A. Nickel metal powder contains over 99% nickel whereas nickel oxide is a chemical compound of nickel + oxygen used for specialized applications requiring the oxide form over pure metal.

Q. How to store nickel powder properly?

A. Nickel readily oxidizes so inert gas blanketing, vacuum packaging or corrosion inhibitors should be used. Cool, dry, indoor storage is necessary to prevent moisture pick-up and agglomeration.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731