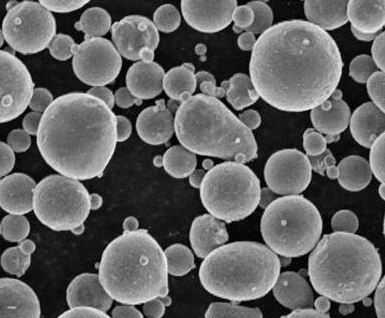

347H stainless steel powder

347H stainless steel powder is a heat-resistant austenitic stainless steel alloy with excellent oxidation and creep resistance properties. It has a higher level of niobium content compared to standard 347 stainless steel, giving it improved high temperature strength and corrosion resistance.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview

347H stainless steel powder is a heat-resistant austenitic stainless steel alloy with excellent oxidation and creep resistance properties. It has a higher level of niobium content compared to standard 347 stainless steel, giving it improved high temperature strength and corrosion resistance.

347H stainless steel powder is widely used in high temperature applications such as gas turbines, aircraft engines, power plants, heat exchangers and in chemical/petrochemical industries due to its ability to withstand operating temperatures up to 850-900°C.

Some key properties and characteristics of 347H stainless steel powder include:

- Excellent high temperature strength and creep resistance

- Good oxidation and corrosion resistance

- Fully austenitic microstructure up to melting point

- Attractive combination of mechanical properties and fabricability

- Higher niobium content improves stability at elevated temperatures

- Can be processed via hot isostatic pressing (HIP) to produce fully dense parts

Composition

347H stainless steel has the following typical composition:

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.04-0.10 |

| Chromium (Cr) | 17.0-19.0 |

| Nickel (Ni) | 9.0-13.0 |

| Niobium (Nb) | 8.5-10.5 |

| Manganese (Mn) | 1.0-2.0 |

| Silicon (Si) | 0.75 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Iron (Fe) | Balance |

The key difference compared to standard 347 stainless steel is the higher niobium content, which gives 347H improved high temperature strength and corrosion resistance. The niobium forms carbides and intermetallic phases that enhance creep strength.

Properties and Characteristics

347H stainless steel powder offers the following properties:

- High temperature strength – Excellent creep rupture strength up to 900°C due to niobium-rich precipitates. It retains strength better than other 300 series stainless steels at extreme temperatures.

- Oxidation resistance – Develops a protective chromium-rich oxide layer at high temperatures with good oxidation resistance in continuous service up to 900°C.

- Corrosion resistance – Resists corrosion in oxidizing, reducing and neutral environments. Provides good resistance to sulphuric acid.

- Phase stability – Fully austenitic microstructure throughout its working temperature range up to melting point. No risk of embrittlement from carbides or intermetallic phases.

- Fabricability – Good formability and weldability by all commercial methods used for stainless steels. Annealing followed by rapid cooling gives optimum properties.

Typical Applications of 347H Stainless Steel Powder

347H stainless steel finds usage in applications that demand exceptional high temperature strength like:

- Gas turbines – combustion cans, transition ducts, exhaust cases

- Jet engine components – exhaust cones, thrust reverser systems, afterburner parts

- Heat exchangers and furnace parts

- Petrochemical equipment for sour gas environments

- Nuclear fuel element cladding

Other major application areas include:

- Coal gasification plants

- Aircraft turbine parts, turbocharger components

- Superheater tubes in boilers

- Automotive valves and turbocharger parts exposed to high temperatures

347H Stainless Steel Powder Specifications

347H stainless steel powder is covered by the following specifications:

| Specification | Grades Available |

|---|---|

| AMS 5646 | Alloy 347H |

| AMS 5508 | Alloy 347H |

It is supplied in various size ranges:

- Particle size – 10-150 microns

- Apparent density – Up to 80% theoretical density

- Flow rate – Good flowability

Suppliers and Pricing

347H stainless steel powder is available from leading global suppliers like:

- Sandvik Osprey

- Hoganas

- Praxair Surface Technologies

- Carpenter Powder Products

Price range – $15 to $30 per kg depending on quantity and particle size. Custom alloys and particle distributions available.

Comparison with Standard 347 Stainless Steel Powder

347H stainless steel powder differs from the standard 347 grade in terms of its higher niobium content, giving it substantially better high temperature strength:

| Parameter | 347H Powder | 347 Powder |

|---|---|---|

| Niobium content | 8.5-10.5% | – |

| Continuous operating temp | Up to 900°C | Up to 870°C |

| Tensile strength at 650°C | >100 MPa | <90 MPa |

| Creep rupture strength | Excellent | Moderate |

| Oxidation resistance | Very good | Good |

| Cost | Higher | Lower |

The higher levels of niobium in 347H lead to the formation of strengthening precipitates that give it the capability to withstand extreme operating temperatures over longer terms with strength and oxidation resistance better than 347 stainless.

Key Considerations for 347H Stainless Steel Powder

Here are some key advantages and limitations to consider when using 347H powder:

Advantages

- Outstanding high temperature strength and corrosion resistance

- Fully austenitic structure ensures excellent fabricability

- Develops protective chromium oxide layer against oxidizing conditions

- Retains ductility better than other high temp alloys like 316H

- No risk of embrittlement up to melting point

Limitations

- More expensive than standard 300 series stainless steels

- Lower thermal conductivity than carbon steel alloys

- Requires careful processing and rapid cooling rates after annealing

- Subject to sigma phase embrittlement if held between 550-850°C

FAQs

Is 347H stainless steel powder weldable?

Yes, 347H powder can be welded using all commercial techniques suitable for austenitic stainless steels. Special considerations like using high heat input and minimum number of passes applies. Post-weld annealing is recommended.

What are typical uses for 347H powder?

Main uses are gas turbines, jet engines, petrochemical equipment, heat exchangers and other extreme temperature applications requiring good environmental resistance.

Does 347H develop carbides during processing or exposure?

No, the fully austenitic structure of 347H prevents carbide precipitation throughout its working range, eliminating risk of embrittlement.

Is 347H susceptible to sensitization during welding?

Yes it can become susceptible to intergranular corrosion if held between 500-900°C. Rapid cooling is required after welding or annealing.

How does 347H differ from 310 and 330 stainless grades?

Compared to 310 and 330, 347H offers better high temperature strength thanks to its higher niobium content. But 310 has better sulphuric acid resistance.

Conclusion

To summarize, 347H stainless steel powder provides an exceptional combination of high temperature mechanical properties and oxidation resistance better than standard 300 series stainless alloys.

With its higher niobium content for strengthening, 347H powder enables long term service in extreme environments up to 900°C like gas turbines, chemical plants and power generators. Careful attention to processing and heat treatment is needed to gain optimum performance.

347H powder can offer designers significantly higher operating temperatures and longer component lifespans compared to 347 powder. The much improved high temperature properties do come at a cost premium over standard grades.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731