Best IN939 Powder for 3D Printing in 2024

IN939 powder is a nickel-based superalloy that exhibits exceptional mechanical properties and high resistance to corrosion and oxidation. It is primarily composed of nickel, chromium, cobalt, molybdenum, and tantalum. This composition gives IN939 powder its remarkable strength, heat resistance, and stability at elevated temperatures.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview of IN939 Powder for 3D Printing

IN939 is a high-performance nickel-based superalloy powder designed for additive manufacturing of critical components needing exceptional mechanical properties at high temperatures. This article provides a comprehensive guide to IN939 powder for 3D printing applications across aerospace, automotive, energy and industrial sectors.

Key aspects covered include IN939 composition, properties, print parameters, applications, specifications, suppliers, handling, inspection, comparisons to alternatives, advantages and limitations, and frequently asked questions. Quantitative data is presented in easy-to-reference tables.

Composition of IN939 Powder

IN939 has a complex precipitation hardening alloy composition:

| Element | Weight % | Purpose |

|---|---|---|

| Nickel | Balance | Principal matrix element |

| Chromium | 15 – 18 | Oxidation resistance |

| Aluminum | 3.8 – 4.8 | Precipitation hardening |

| Titanium | 0.9 – 1.4 | Precipitation hardening |

| Cobalt | 12 – 15 | Solid solution strengthening |

| Tantalum | 3.8 – 4.8 | Carbide former |

| Carbon | 0.05 – 0.15 | Carbide former |

| Boron | 0.006 – 0.012 | Grain boundary strengthener |

Trace quantities of zirconium, magnesium and sulphur are also added for enhanced properties.

Properties of IN939 Powder

IN939 possesses an exceptional combination of properties:

| Property | Description |

|---|---|

| High strength | Excellent tensile and creep rupture strength up to 1050°C |

| Thermal stability | Strength maintained up to 1000°C |

| Creep resistance | High stress-rupture life at high temperatures |

| Oxidation resistance | Forms protective Cr2O3 oxide scale |

| Thermal fatigue resistance | Resists cracking during thermal cycling |

| Phase stability | Microstructure stable after prolonged exposures |

| Corrosion resistance | Resistant to hot corrosion, oxidation, sulfidation |

The properties enable use under extreme thermal and mechanical loads.

3D Printing Parameters for IN939 Powder

Typical AM processing parameters for IN939 include:

| Parameter | Typical value | Purpose |

|---|---|---|

| Layer thickness | 20-50 μm | Resolution vs build speed |

| Laser power | 250-500 W | Sufficient melting without evaporation |

| Scan speed | 800-1200 mm/s | Density vs production rate |

| Hatch spacing | 100-200 μm | Mechanical properties |

| Support structure | Minimal | Easy removal |

| Hot isostatic pressing | 1160°C, 100 MPa, 3h | Eliminate porosity |

Parameters are optimized for attributes like density, microstructure, build rate, and post-processing requirements.

Applications of 3D Printed IN939 Parts

Additively manufactured IN939 components serve critical applications including:

| Industry | Components |

|---|---|

| Aerospace | Turbine blades, vanes, combustors |

| Power generation | Hot gas path parts, heat exchangers |

| Automotive | Turbocharger wheels, valves |

| Chemical processing | Pumps, valves, reaction vessels |

Benefits over conventionally processed IN939 include complex geometries and reduced lead time.

Specifications of IN939 Powder for 3D Printing

IN939 powder for AM must meet exacting specifications:

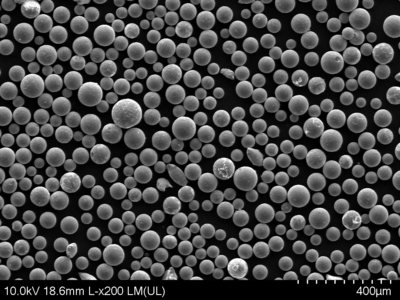

| Parameter | Specification |

|---|---|

| Particle size | 15-45 μm typical |

| Particle shape | Spherical morphology |

| Apparent density | > 4 g/cc |

| Tap density | > 6 g/cc |

| Hall flow rate | > 23 sec for 50 g |

| Purity | >99.9% |

| Oxygen content | <100 ppm |

Tighter tolerances, custom size distributions, and controlled impurity levels available.

Suppliers of IN939 Powder

Reputable suppliers of IN939 powder include:

| Supplier | Location |

|---|---|

| Met3DP | China |

| Carpenter Additive | USA |

| Praxair | USA |

| AP&C | Canada |

| Erasteel | Sweden |

| AMETEK | USA |

Pricing for IN939 powder ranges from $110/kg to over $220/kg based on quality and order volume.

Handling and Storage of IN939 Powder

As a reactive powder, careful handling of IN939 is needed:

- Store sealed containers in a cool, inert atmosphere

- Prevent contact with moisture, oxygen, acids

- Use properly grounded equipment

- Avoid dust accumulation to minimize explosion risk

- Local exhaust ventilation recommended

- Wear appropriate PPE while handling

Proper techniques and controls prevent IN939 powder oxidation or contamination.

Inspection and Testing of IN939 Powder

IN939 powder is validated using:

| Method | Parameters Tested |

|---|---|

| Sieve analysis | Particle size distribution |

| SEM imaging | Particle morphology |

| EDX | Chemistry and composition |

| XRD | Phases present |

| Pycnometry | Density |

| Hall flow rate | Powder flowability |

Testing per applicable ASTM standards ensures batch consistency.

Comparing IN939 to Alternative Alloy Powders

IN939 compares to other Ni-based superalloys as:

| Alloy | High Temperature Strength | Cost | Printability | Ductility |

|---|---|---|---|---|

| IN939 | Excellent | High | Excellent | Low |

| IN738 | Good | Medium | Excellent | Medium |

| IN718 | Fair | Low | Good | Excellent |

| Hastelloy X | Excellent | High | Fair | Medium |

For balanced properties and processability, IN939 supersedes alternatives like IN718 Powder or Hastelloy X Powder.

Pros and Cons of IN939 Powder for 3D Printing

| Pros | Cons |

|---|---|

| Exceptional high temperature strength | Expensive compared to IN718 |

| Excellent oxidation and creep resistance | Significant parameter optimization needed |

| Complex geometries feasible | Limited room temperature ductility |

| Faster processing than cast/wrought | Controlled storage and handling environment |

| Comparable properties to cast alloy | Difficult to machine after printing |

IN939 enables high-performance printed parts but with higher costs and controlled processing needs.

Frequently Asked Questions about IN939 Powder for 3D Printing

Q: What particle size range works best for printing IN939?

A: A particle size range of 15-45 microns provides good flowability combined with high resolution and density. Finer particles below 10 microns can improve density and surface finish.

Q: Does IN939 require any post-processing after 3D printing?

A: Post processes like hot isostatic pressing, heat treatment, and machining are usually needed to eliminate porosity, relieve stresses, and achieve final tolerances and surface finish.

Q: What precision can be achieved with IN939 printed parts?

A: After post-processing, dimensional accuracy and surface finish comparable to CNC machined parts can be achieved with IN939 AM components.

Q: Are support structures necessary for printing IN939 powder?

A: Minimal supports are recommended for complex channels and overhangs to prevent deformation and facilitate easy removal. IN939 powder has good flowability.

Q: What alloy powder is the closest alternative to IN939 for AM?

A: IN738 is the closest alternative in terms of balanced properties and maturity for additive manufacturing. Other alloys like IN718 or Hastelloy X have some trade-offs.

Q: Is IN939 compatible with direct metal laser sintering (DMLS)?

A: Yes, IN939 is readily processable by major powder bed fusion techniques including DMLS along with selective laser melting (SLM) and electron beam melting (EBM).

Q: What density is achievable with 3D printed IN939 components?

A: With optimized parameters, densities over 99% are achievable, matching properties of traditionally processed IN939 products.

Q: How do the properties of printed IN939 compare to cast alloy?

A: Additively manufactured IN939 exhibits comparable or better mechanical properties and microstructure compared to conventional cast and wrought forms.

Q: What defects can occur when printing with IN939 powder?

A: Potential defects are cracking, distortion, porosity, surface roughness, incomplete fusion etc. Most can be prevented by proper parameter optimization and powder quality.

Q: Is hot isostatic pressing (HIP) mandatory for IN939 AM parts?

A: HIP eliminates internal voids and improves fatigue resistance. For less demanding applications, heat treatment alone may suffice instead of HIP.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731