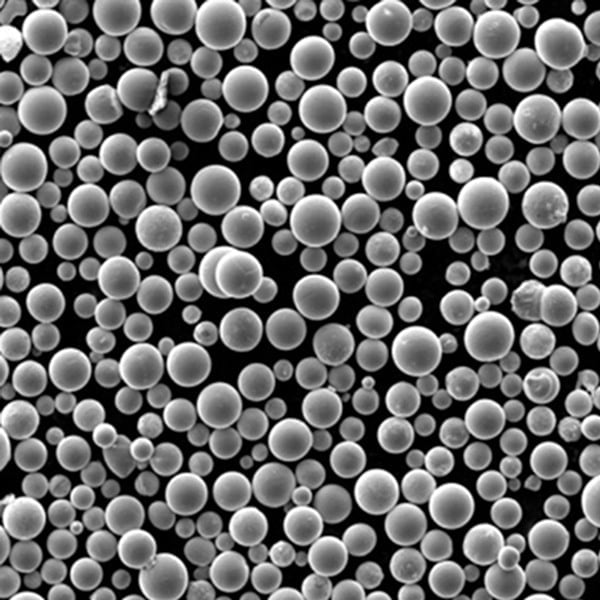

Maraging Steel C300 Powder

In the ever-evolving world of additive manufacturing, the quest for high-performance materials has led to the development of specialized alloys, each engineered to cater to specific industrial demands. Among these, Maraging Steel C300 Powder has emerged as a powerhouse, renowned for its exceptional strength, toughness, and resistance to corrosion.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

In the ever-evolving world of additive manufacturing, the quest for high-performance materials has led to the development of specialized alloys, each engineered to cater to specific industrial demands. Among these, Maraging Steel C300 Powder has emerged as a powerhouse, renowned for its exceptional strength, toughness, and resistance to corrosion. This article delves into the intricacies of this remarkable material, exploring its composition, properties, applications, and the advantages it brings to the world of additive manufacturing.

Overview of Maraging Steel C300 Powder

Maraging Steel C300 Powder is a category of ultra-high-strength steels that derive their remarkable properties from a unique aging process. The term “maraging” itself is a portmanteau of “martensitic” and “aging,” reflecting the material’s ability to transform its microstructure through a careful heat treatment process. This aging process precipitates intermetallic compounds within the steel’s martensitic matrix, resulting in a material that boasts exceptional mechanical properties.

Composition and Properties

| Component | Typical Composition (%) |

|---|---|

| Nickel | 18-19 |

| Cobalt | 9 |

| Molybdenum | 4.5-5.2 |

| Titanium | 0.6-0.8 |

| Aluminum | 0.05-0.15 |

| Carbon | ≤ 0.03 |

| Iron | Balance |

Maraging Steel C300 Powder exhibits an impressive array of properties that make it a prime candidate for various demanding applications:

- Tensile Strength: With a typical tensile strength ranging from 1900 MPa to 2100 MPa, Maraging Steel C300 Powder outperforms many conventional high-strength alloys.

- Yield Strength: The material’s yield strength can reach up to 1800 MPa, ensuring exceptional resistance to plastic deformation under high loads.

- Toughness: Despite its remarkable strength, Maraging Steel C300 Powder maintains high toughness, making it resistant to fracture and crack propagation.

- Corrosion Resistance: The low carbon content and the addition of molybdenum contribute to the material’s excellent resistance to various forms of corrosion, including stress corrosion cracking.

- Dimensional Stability: Maraging Steel C300 Powder exhibits minimal distortion during the aging process, ensuring dimensional stability and precision in additive manufacturing applications.

Industrial Applications

The unique properties of Maraging Steel C300 Powder have made it a sought-after material in a variety of industries, where high strength, toughness, and corrosion resistance are paramount:

| Application | Description |

|---|---|

| Aerospace and Aviation | Used in the production of landing gear components, turbine blades, and other critical aerospace parts. |

| Tooling and Mold Manufacturing | Employed in the fabrication of injection molds, die-casting tools, and extrusion dies due to its high strength and wear resistance. |

| Oil and Gas Industry | Utilized in downhole components, drill bits, and other equipment subjected to extreme conditions. |

| Additive Manufacturing | Widely used in 3D printing processes, such as selective laser melting (SLM) and direct metal laser sintering (DMLS). |

Specifications and Standards

Maraging Steel C300 Powder is available in various grades and specifications, ensuring compatibility with diverse industrial applications and manufacturing processes. Some of the commonly used specifications include:

| Specification | Description |

|---|---|

| ASTM A957 | Standard specification for investment castings, including maraging steels. |

| AMS 6514 | Aerospace Material Specification for maraging steel castings. |

| AMS 6529 | Aerospace Material Specification for maraging steel forgings. |

Suppliers and Pricing

Several reputable suppliers offer Maraging Steel C300 Powder for additive manufacturing applications. The pricing can vary based on factors such as quantity, purity, and particle size distribution. Some notable suppliers include:

| Supplier | Price Range (per kg) |

|---|---|

| Carpenter Technology | $100 – $150 |

| Sandvik | $120 – $180 |

| Höganäs | $110 – $170 |

Pros and Cons

Like any material, Maraging Steel C300 Powder has its advantages and limitations, which should be carefully evaluated for specific applications:

| Pros | Cons |

|---|---|

| Exceptional strength and toughness | Higher cost compared to some conventional steels |

| Excellent corrosion resistance | Requires precise heat treatment for optimal properties |

| Dimensional stability during aging | Limited availability of specific grades and sizes |

| Versatility in additive manufacturing processes | Potential for cracking in certain welding processes |

FAQs

Q1: How does Maraging Steel C300 Powder compare to other high-strength steels?

A1: Maraging Steel C300 Powder offers superior strength and toughness compared to many conventional high-strength steels, while maintaining excellent corrosion resistance and dimensional stability. Its unique aging process and carefully controlled composition contribute to its exceptional mechanical properties.

Q2: Can Maraging Steel C300 Powder be used in traditional manufacturing processes like casting or forging?

A2: Yes, Maraging Steel C300 Powder can be used in traditional manufacturing processes, such as investment casting and forging. However, it is particularly well-suited for additive manufacturing techniques like selective laser melting (SLM) and direct metal laser sintering (DMLS), where its high strength and toughness are highly advantageous.

Q3: What are the typical post-processing steps for additively manufactured parts made from Maraging Steel C300 Powder?

A3: After the additive manufacturing process, parts made from Maraging Steel C300 Powder typically undergo an aging heat treatment to precipitate intermetallic compounds and achieve the desired mechanical properties. Additional post-processing steps may include surface finishing, machining, or heat treatment for stress relief, depending on the specific application and requirements.

Q4: Is Maraging Steel C300 Powder compatible with other materials for multi-material additive manufacturing?

A4: While Maraging Steel C300 Powder is primarily used as a standalone material, it can be combined with other compatible materials in multi-material additive manufacturing processes, such as laser metal deposition (LMD) or directed energy deposition (DED). However, careful consideration should be given to factors like thermal expansion coefficients and potential for metallurgical interactions between the materials.

Q5: Are there any specific safety precautions or handling requirements for Maraging Steel C300 Powder?

A5: As with any metal powder, proper safety measures should be taken when handling Maraging Steel C300 Powder to minimize the risk of inhalation or exposure. This may include the use of personal protective equipment (PPE), adequate ventilation, and proper storage and disposal procedures. Additionally, it is essential to follow the supplier’s specific safety guidelines and comply with relevant regulations.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731