Nickel Alloy 601 Powder

Before we delve into the details, let’s start with a brief overview of Nickel Alloy 601 Powder. This alloy, also known as Inconel 601, is a nickel-chromium alloy developed by Special Metals Corporation (now part of Huntington Alloys Corporation).

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

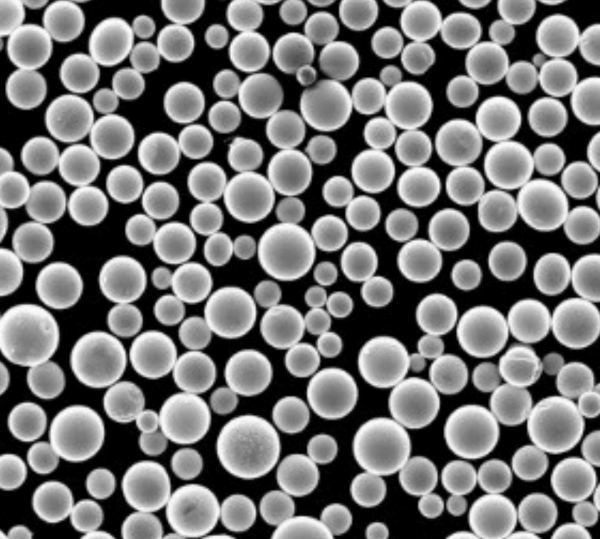

Have you ever wondered what makes certain components in high-performance machines and engines so resilient and durable? The answer often lies in the remarkable properties of specialized alloys like Nickel Alloy 601. This powerful material, available in powder form, has become a go-to choice for industries that demand exceptional heat resistance, corrosion resistance, and strength at elevated temperatures. In this comprehensive guide, we’ll dive deep into the world of Nickel Alloy 601 Powder, exploring its composition, properties, applications, and everything else you need to know about this versatile alloy.

Overview of Nickel Alloy 601 Powder

Before we delve into the details, let’s start with a brief overview of Nickel Alloy 601 Powder. This alloy, also known as Inconel 601, is a nickel-chromium alloy developed by Special Metals Corporation (now part of Huntington Alloys Corporation). It is designed to withstand extreme temperatures and harsh environments, making it ideal for applications where high-temperature resistance and corrosion protection are paramount.

| Property | Value |

|---|---|

| Composition | Nickel (Ni) – 60.5%, Chromium (Cr) – 23%, Aluminum (Al) – 1.4%, Iron (Fe) – 14% |

| Melting Point | 2,615°F (1,435°C) |

| Density | 0.297 lb/in³ (8.22 g/cm³) |

| Tensile Strength | 90 ksi (620 MPa) at room temperature |

| Yield Strength | 35 ksi (240 MPa) at room temperature |

| Elongation | 40% at room temperature |

As you can see, Nickel Alloy 601 Powder is primarily composed of nickel, chromium, and iron, with small amounts of aluminum and other trace elements. This carefully crafted composition gives the alloy its exceptional properties, including high-temperature strength, oxidation resistance, and corrosion resistance.

Nickel Alloy 601 Powder Composition and Properties

The unique composition of Nickel Alloy 601 Powder is what sets it apart from other alloys. Let’s take a closer look at the key elements and their contributions:

| Element | Percentage | Contribution |

|---|---|---|

| Nickel (Ni) | 60.5% | Provides high-temperature strength, oxidation resistance, and corrosion resistance |

| Chromium (Cr) | 23% | Enhances corrosion resistance and oxidation resistance at high temperatures |

| Aluminum (Al) | 1.4% | Improves oxidation resistance and strength at high temperatures |

| Iron (Fe) | 14% | Adds strength and reduces cost |

Nickel, the primary element, is responsible for the alloy’s exceptional high-temperature strength and resistance to oxidation and corrosion. Chromium further enhances these properties, particularly at elevated temperatures. Aluminum plays a crucial role in improving oxidation resistance and strength at high temperatures, while iron contributes to the overall strength and helps reduce the cost of the alloy.

But it’s not just the composition that makes Nickel Alloy 601 Powder so remarkable. Its unique properties, such as a high melting point of 2,615°F (1,435°C), excellent tensile strength, and good elongation, make it suitable for a wide range of demanding applications.

Industrial Applications of Nickel Alloy 601 Powder

Nickel Alloy 601 Powder finds applications in various industries where high-temperature resistance, corrosion resistance, and strength are essential. Here are some of the key applications:

| Industry | Applications |

|---|---|

| Aerospace | Jet engine components, combustion chambers, exhaust systems |

| Automotive | Turbocharger components, exhaust manifolds, exhaust valves |

| Chemical Processing | Reactor vessels, heat exchangers, piping systems |

| Power Generation | Gas turbine components, boiler components, steam line components |

| Oil and Gas | Downhole tools, well-head equipment, piping systems |

In the aerospace industry, Nickel Alloy 601 Powder is used in the manufacture of jet engine components, combustion chambers, and exhaust systems, where its ability to withstand extreme temperatures and resist oxidation is crucial. Similarly, in the automotive industry, it is used in turbocharger components, exhaust manifolds, and exhaust valves, thanks to its high-temperature strength and corrosion resistance.

The chemical processing industry relies on Nickel Alloy 601 Powder for reactor vessels, heat exchangers, and piping systems, where its resistance to harsh chemicals and high temperatures is essential. In the power generation sector, it is used in gas turbine components, boiler components, and steam line components, ensuring reliable performance and longevity.

The oil and gas industry also benefits from the properties of Nickel Alloy 601 Powder, using it in downhole tools, well-head equipment, and piping systems exposed to extreme conditions.

Nickel Alloy 601 Powder Specifications and Standards

When working with Nickel Alloy 601 Powder, it’s essential to understand the specifications and standards that govern its production and use. Here are some of the key specifications and standards:

| Specification/Standard | Description |

|---|---|

| AMS 5599 | Covers the requirements for Nickel Alloy 601 powder for powder metallurgy applications |

| AMS 5591 | Covers the requirements for Nickel Alloy 601 bars, forgings, and rings |

| ASTM B166 | Covers the requirements for Nickel Alloy 601 ingots, bars, and forgings |

| ASME SB-166 | Covers the requirements for Nickel Alloy 601 seamless pipe and tube |

These specifications and standards ensure consistent quality, composition, and performance of Nickel Alloy 601 Powder and its associated products. Adherence to these standards is crucial for manufacturers and end-users to ensure compliance with industry regulations and customer requirements.

Nickel Alloy 601 Powder Suppliers and Pricing

As with any specialized material, sourcing Nickel Alloy 601 Powder from reputable suppliers is essential. Here are some of the leading suppliers of Nickel Alloy 601 Powder:

| Supplier | Location | Pricing (Approximate) |

|---|---|---|

| Kennametal Inc. | United States | $50 – $100 per pound |

| Sandvik Materials Technology | Sweden | $60 – $120 per pound |

| Carpenter Technology Corporation | United States | $70 – $130 per pound |

| VBC Group | United Kingdom | $80 – $150 per pound |

The pricing of Nickel Alloy 601 Powder can vary significantly based on factors such as supplier, quantity, and market conditions. The approximate pricing range provided here is for reference only and may change over time.

Pros and Cons of Nickel Alloy 601 Powder

Like any material, Nickel Alloy 601 Powder has its advantages and limitations. Let’s take a look at some of the pros and cons:

| Pros | Cons |

|---|---|

| Excellent high-temperature strength and oxidation resistance | More expensive than some other alloys |

| Superior corrosion resistance in various environments | Susceptible to stress corrosion cracking in certain environments |

| Good weldability and fabrication properties | Limited availability and supply compared to more common alloys |

| Maintains mechanical properties at elevated temperatures | Requires specialized manufacturing processes |

While Nickel Alloy 601 Powder offers exceptional high-temperature strength, oxidation resistance, and corrosion resistance, it comes at a higher cost compared to some other alloys. Additionally, it may be susceptible to stress corrosion cracking in certain environments and has limited availability and supply compared to more common alloys. However, its unique properties often outweigh these limitations, making it a preferred choice for demanding applications.

FAQ

| Question | Answer |

|---|---|

| What is Nickel Alloy 601 Powder used for? | Nickel Alloy 601 Powder is primarily used in applications that require high-temperature strength, oxidation resistance, and corrosion resistance, such as jet engine components, turbine blades, and chemical processing equipment. |

| How does Nickel Alloy 601 Powder compare to other nickel-based alloys? | Compared to other nickel-based alloys, Nickel Alloy 601 Powder offers superior high-temperature strength and oxidation resistance. However, it may have slightly lower corrosion resistance in certain environments compared to alloys like Inconel 625. |

| Can Nickel Alloy 601 Powder be welded? | Yes, Nickel Alloy 601 Powder has good weldability properties, making it suitable for welding applications. However, proper welding techniques and procedures must be followed to ensure optimal performance. |

| What are the typical applications of Nickel Alloy 601 Powder in the aerospace industry? | In the aerospace industry, Nickel Alloy 601 Powder is commonly used in the manufacture of jet engine components, combustion chambers, exhaust systems, and other components exposed to extreme temperatures and harsh environments. |

| How does Nickel Alloy 601 Powder compare to other materials in terms of cost? | Nickel Alloy 601 Powder is generally more expensive than some other alloys due to its specialized composition and properties. However, its exceptional performance and durability can often justify the higher initial cost in demanding applications. |

Remember, while this FAQ covers some common questions, it’s always best to consult with experts or refer to official documentation for specific inquiries or applications.

Conclusion

Nickel Alloy 601 Powder is a remarkable material that has revolutionized various industries with its exceptional high-temperature strength, oxidation resistance, and corrosion resistance. From jet engines to chemical processing equipment, this versatile alloy has proven its worth time and again, making it a go-to choice for engineers and manufacturers seeking superior performance in extreme conditions.

While Nickel Alloy 601 Powder may come at a higher cost and have specific limitations, its unique properties often outweigh these drawbacks, making it an invaluable asset in the world of high-performance materials. As technology continues to advance and demand for more robust and durable components increases, Nickel Alloy 601 Powder will undoubtedly continue to play a crucial role in pushing the boundaries of what’s possible.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731