Product

Product Category

stainless steel 304 Powder for 3D Printing

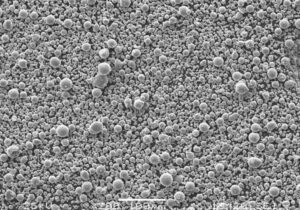

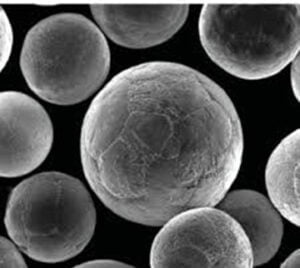

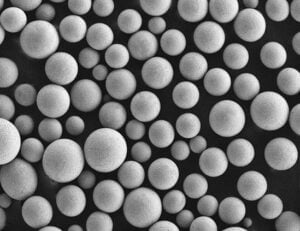

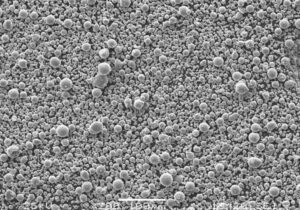

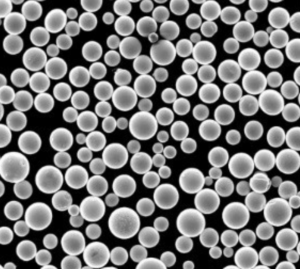

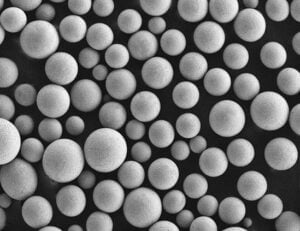

304 powder is a form of stainless steel powder that is widely used in various industries due to its exceptional properties. It is composed of iron, chromium, and nickel, which give it excellent corrosion resistance, high strength, and good formability. The powder form allows for easy processing and customization according to specific requirements.

Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Stainless Steel 330 Powder

Stainless steel 330 powder is a highly alloyed austenitic stainless steel that offers excellent high temperature strength and corrosion resistance. It has good ductility and toughness even at extreme temperatures up to 1150°C. The key features of stainless steel 330 powder include:

Stainless Steel 330 Powder Key Features:

- Excellent high temperature strength up to 1150°C

- Outstanding corrosion resistance

Stainless Steel 410 Powder

Stainless steel is a versatile and widely used alloy known for its excellent corrosion resistance, durability, and strength. Among the various grades of stainless steel, 410 is a martensitic stainless steel that is particularly well-suited for applications requiring high strength and moderate corrosion resistance.

Stainless Steel 420 Powder

Stainless steel 420 powder is a martensitic grade stainless steel in powder form. It offers high hardness and moderate corrosion resistance, making it suitable for tooling applications requiring high wear resistance.

Some key properties and characteristics of 420 stainless steel powder include:

- High hardness and wear resistance

- Moderate corrosion resistance

- Can be heat treated to increase hardness

- Good dimensional stability in hardened state

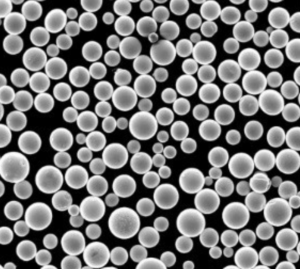

- Available in various particle size distributions

Stainless Steel OP431 Powder

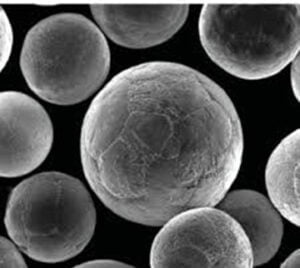

Stainless steel OP431 powder is a powdered form of stainless steel that consists of iron, chromium, nickel, and other alloying elements. It is manufactured through a specialized process called atomization, where molten stainless steel is rapidly cooled using gas or water, resulting in the formation of fine metal particles.

T15 Powder

T15 powder is a tungsten carbide-cobalt cemented carbide powder that provides an exceptional combination of hardness, strength, and toughness. It contains a high percentage of tungsten carbide along with 15% cobalt as the binder phase.

TC11 Powder : A Comprehensive Guide

TC11 powder, also known as Titanium Carbide 11, is a cutting-edge material with remarkable properties. It is composed of titanium and carbon atoms, resulting in a high-strength, lightweight powder that exhibits excellent wear resistance and thermal stability.

TC18 Powder : Unlocking the Power of Titanium Carbide

TC18 powder refers to a fine powder composed of titanium carbide (TiC) particles. Titanium carbide, a hard ceramic compound, is renowned for its exceptional hardness, high melting point, and impressive resistance to wear and corrosion. TC18 powder is produced by finely grinding titanium carbide into a powdered form, allowing for its versatile utilization in numerous industries.

TC4 ELI Powder

TC4 ELI powder is a titanium alloy known for its exceptional mechanical properties and biocompatibility. It is a variant of Ti-6Al-4V alloy, specifically developed for critical applications in industries such as aerospace, medical, automotive, and sports equipment manufacturing. TC4 ELI powder exhibits enhanced purity and reduced interstitial elements, making it highly desirable for various advanced applications.

Ti-6Al-4V Titanium Alloy Powder

Low oxygen pure titanium powder is the basis of powder metallurgy titanium production, is also one of the company’s leading products. At present, the company through HDH process, and oxygen control technology, the production of high-end ultra-fine low-oxygen pure titanium powder in the international leading position in the indicators, with the characteristics of ultrafine powder size, ultra-low oxygen content, low impurities, to achieve the large-scale production of high-end low-oxygen pure titanium powder.

Ti22Al25Nb Powder

Ti22Al25Nb powder is an innovative alloy powder composed of titanium (Ti), aluminum (Al), and niobium (Nb). This unique combination offers exceptional properties that make it highly sought after in various industries. From aerospace to medical and energy sectors, Ti22Al25Nb powder has the potential to redefine material performance and open up new horizons.

Ti3Al Powder

Ti3Al powder, also known as titanium aluminide powder, is an intermetallic compound made from titanium and aluminum. It has attracted significant interest in recent years due to its exceptional high temperature properties and light weight compared to other titanium alloys.

Ti3Al powder can be produced through various methods including gas atomization, mechanical alloying, and thermal plasma spheroidization. It is available in various particle sizes, morphologies, and purity levels to suit different applications. The main applications of Ti3Al powder are in aerospace, automotive, biomedical, and chemical process industries.

Ti45Al8Nb Powder

Ti45Al8Nb powder is a revolutionary material that has gained significant attention in various industries due to its exceptional properties. This article explores the composition, manufacturing process, physical and mechanical properties, as well as the applications of Ti45Al8Nb powder.

Ti45Nb Powder for Additive Manufacturing

Ti45Nb powder, a marvel of material science, is making waves in the realm of additive manufacturing.

| Metal Powder | Size | Quantity | Price/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

Ti48Al2Cr2Nb powder

Ti48Al2Cr2Nb powder is a remarkable alloy that has gained significant attention in recent years due to its exceptional properties and applications in various industries. This article explores the composition, synthesis methods, properties, and diverse applications of Ti48Al2Cr2Nb powder. From aerospace engineering to biomedical advancements, this alloy has the potential to revolutionize several fields. Let’s delve into the fascinating world of Ti48Al2Cr2Nb powder and uncover its wide-ranging possibilities.

stainless steel 304 Powder for 3D Printing

304 powder is a form of stainless steel powder that is widely used in various industries due to its exceptional properties. It is composed of iron, chromium, and nickel, which give it excellent corrosion resistance, high strength, and good formability. The powder form allows for easy processing and customization according to specific requirements.

Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Stainless Steel 330 Powder

Stainless steel 330 powder is a highly alloyed austenitic stainless steel that offers excellent high temperature strength and corrosion resistance. It has good ductility and toughness even at extreme temperatures up to 1150°C. The key features of stainless steel 330 powder include:

Stainless Steel 330 Powder Key Features:

- Excellent high temperature strength up to 1150°C

- Outstanding corrosion resistance

Stainless Steel 410 Powder

Stainless steel is a versatile and widely used alloy known for its excellent corrosion resistance, durability, and strength. Among the various grades of stainless steel, 410 is a martensitic stainless steel that is particularly well-suited for applications requiring high strength and moderate corrosion resistance.

Stainless Steel 420 Powder

Stainless steel 420 powder is a martensitic grade stainless steel in powder form. It offers high hardness and moderate corrosion resistance, making it suitable for tooling applications requiring high wear resistance.

Some key properties and characteristics of 420 stainless steel powder include:

- High hardness and wear resistance

- Moderate corrosion resistance

- Can be heat treated to increase hardness

- Good dimensional stability in hardened state

- Available in various particle size distributions

Stainless Steel OP431 Powder

Stainless steel OP431 powder is a powdered form of stainless steel that consists of iron, chromium, nickel, and other alloying elements. It is manufactured through a specialized process called atomization, where molten stainless steel is rapidly cooled using gas or water, resulting in the formation of fine metal particles.

T15 Powder

T15 powder is a tungsten carbide-cobalt cemented carbide powder that provides an exceptional combination of hardness, strength, and toughness. It contains a high percentage of tungsten carbide along with 15% cobalt as the binder phase.

TC11 Powder : A Comprehensive Guide

TC11 powder, also known as Titanium Carbide 11, is a cutting-edge material with remarkable properties. It is composed of titanium and carbon atoms, resulting in a high-strength, lightweight powder that exhibits excellent wear resistance and thermal stability.

TC18 Powder : Unlocking the Power of Titanium Carbide

TC18 powder refers to a fine powder composed of titanium carbide (TiC) particles. Titanium carbide, a hard ceramic compound, is renowned for its exceptional hardness, high melting point, and impressive resistance to wear and corrosion. TC18 powder is produced by finely grinding titanium carbide into a powdered form, allowing for its versatile utilization in numerous industries.

TC4 ELI Powder

TC4 ELI powder is a titanium alloy known for its exceptional mechanical properties and biocompatibility. It is a variant of Ti-6Al-4V alloy, specifically developed for critical applications in industries such as aerospace, medical, automotive, and sports equipment manufacturing. TC4 ELI powder exhibits enhanced purity and reduced interstitial elements, making it highly desirable for various advanced applications.

Ti-6Al-4V Titanium Alloy Powder

Low oxygen pure titanium powder is the basis of powder metallurgy titanium production, is also one of the company’s leading products. At present, the company through HDH process, and oxygen control technology, the production of high-end ultra-fine low-oxygen pure titanium powder in the international leading position in the indicators, with the characteristics of ultrafine powder size, ultra-low oxygen content, low impurities, to achieve the large-scale production of high-end low-oxygen pure titanium powder.

Ti22Al25Nb Powder

Ti22Al25Nb powder is an innovative alloy powder composed of titanium (Ti), aluminum (Al), and niobium (Nb). This unique combination offers exceptional properties that make it highly sought after in various industries. From aerospace to medical and energy sectors, Ti22Al25Nb powder has the potential to redefine material performance and open up new horizons.

Ti3Al Powder

Ti3Al powder, also known as titanium aluminide powder, is an intermetallic compound made from titanium and aluminum. It has attracted significant interest in recent years due to its exceptional high temperature properties and light weight compared to other titanium alloys.

Ti3Al powder can be produced through various methods including gas atomization, mechanical alloying, and thermal plasma spheroidization. It is available in various particle sizes, morphologies, and purity levels to suit different applications. The main applications of Ti3Al powder are in aerospace, automotive, biomedical, and chemical process industries.

Ti45Al8Nb Powder

Ti45Al8Nb powder is a revolutionary material that has gained significant attention in various industries due to its exceptional properties. This article explores the composition, manufacturing process, physical and mechanical properties, as well as the applications of Ti45Al8Nb powder.

Ti45Nb Powder for Additive Manufacturing

Ti45Nb powder, a marvel of material science, is making waves in the realm of additive manufacturing.

| Metal Powder | Size | Quantity | Price/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

Ti48Al2Cr2Nb powder

Ti48Al2Cr2Nb powder is a remarkable alloy that has gained significant attention in recent years due to its exceptional properties and applications in various industries. This article explores the composition, synthesis methods, properties, and diverse applications of Ti48Al2Cr2Nb powder. From aerospace engineering to biomedical advancements, this alloy has the potential to revolutionize several fields. Let’s delve into the fascinating world of Ti48Al2Cr2Nb powder and uncover its wide-ranging possibilities.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731