Pure Aluminum Powder

Pure aluminum powder refers to aluminum powder produced from just aluminum without the addition of other alloying elements. It exhibits low density, high thermal and electrical conductivity, ductility, excellent corrosion resistance, and reflectivity.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview of Pure Aluminum Powder

Pure aluminum powder refers to aluminum powder produced from just aluminum without the addition of other alloying elements. It exhibits low density, high thermal and electrical conductivity, ductility, excellent corrosion resistance, and reflectivity.

Key features of pure aluminum powder include:

- Unalloyed aluminum with 99%+ purity

- Highly reactive with high affinity to oxygen

- Low melting point and excellent thermal conductivity

- Lightweight with density around 2.7 g/cc

- Soft and ductile for deformation processing

- Available in various particle sizes and morphologies

Pure aluminum powder is used for protective coatings, pyrotechnic compositions, fuel additives, 3D printing, and other applications requiring pure aluminum properties.

This article provides a comprehensive overview of properties, production methods, applications, specifications, and other details of pure aluminum powder.

Composition of Pure Aluminum Powder

Pure aluminum powder has the following typical composition:

| Element | Weight % |

|---|---|

| Aluminum (Al) | 99%+ |

| Iron (Fe) | 0.35% max |

| Silicon (Si) | 0.10% max |

| Copper (Cu) | 0.05% max |

| Zinc (Zn) | 0.07% max |

| Manganese (Mn) | 0.03% max |

| Magnesium (Mg) | 0.03% max |

| Chromium (Cr) | 0.03% max |

| Others (each) | 0.03% max |

| Others (total) | 0.10% max |

The powder is unalloyed aluminum with minimum 99% aluminum content without additions of other alloying elements. Maximum limits for common impurity elements are specified.

Properties of Pure Aluminum Powder

Pure aluminum powder exhibits the following properties:

| Property | Value |

|---|---|

| Density | 2.70 g/cm3 |

| Melting Point | 660°C |

| Thermal Conductivity | 237 W/m.K |

| Electrical Resistivity | 2.65 microhm-cm |

| Young’s Modulus | 70 GPa |

| Poisson’s Ratio | 0.33 |

| Tensile Strength | 90-115 MPa |

| Elongation | 8-25% |

| Mohs Hardness | 2.75 |

| Oxidation Resistance | Poor |

The low density and softness of aluminum powder make it easy to handle and process for various applications. It has excellent thermal and electrical conductivity. Oxidation resistance is poor and powders require protection from oxidation during storage and use.

Production Methods for Pure Aluminum Powder

There are different production processes used to make pure aluminum powder:

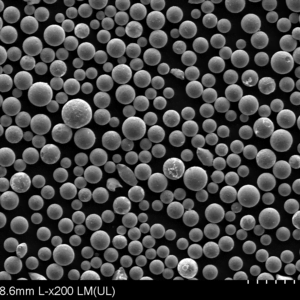

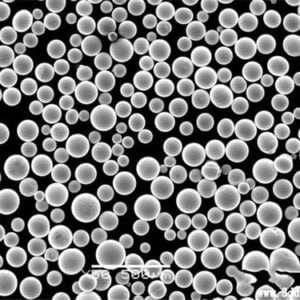

- Atomization – Molten aluminum is broken into droplets using gas or water jets which solidify into powder. Gas atomized powder has spherical morphology.

- Electrolysis – Aluminum is deposited in powder form from alumina electrolyte. Powder is spongy and irregular shaped.

- Milling – Ball milling of aluminum flakes produces flake powders of various sizes and morphologies.

- Chemical Methods – Reactions of aluminum compounds produce fine aluminum powders of high purity.

Atomization is the most common method while special techniques are used for ultrafine or nanoscale aluminum powders. Powder characteristics can be controlled by process parameters.

Applications of Pure Aluminum Powder

Pure aluminum powder is used in the following applications:

- Protective Coatings – Thermal spray coatings to provide corrosion protection for steel surfaces.

- Pyrotechnics – Powder fuel for pyrotechnic compositions due to high flammability.

- Fuel Additive – Added to solid rocket propellants and explosives to improve energetic characteristics.

- 3D Printing – Used in selective laser sintering, direct metal laser sintering (DMLS) additive manufacturing processes.

- Printing Inks – Used in conductive inks for printing of circuits, RFID tags, other electronics.

- Pigments – Flake and atomized powders for paints, plastics, rubber and other coatings.

- Electronics – Pure aluminum bonding wires, contacts, circuits requiring conductivity.

Welding – Used as aluminum powder filler material for welding components and repair.

Specifications of Pure Aluminum Powder

Pure aluminum powder is available under various specifications:

Particle Size: Ranging from 5-150 microns depending on application. Finer atomized powder for AM, coarser grade for coatings.

Purity: From 99% to 99.9% purity based on impurity limits for iron, silicon and other elements.

Morphology: Spherical, irregular and flake type particle shapes. Spherical powder has better flowability.

Coating: Partially oxygen passivated, uncoated and oil coated pure aluminum powders offered.

Grades: Commercial pure, very high purity and technical grades conforming to standards like ASTM B209.

Surface Area: Powder can be tailored as ultrafine nanoscale (up to 20 m2/g) to coarse grades.

Global Suppliers of Pure Aluminum Powder

Some of the major global suppliers of pure aluminum powder include:

| Company | Country |

|---|---|

| Alfa Aesar | United States |

| Valimet Inc. | United States |

| Makin Metal Powders | United Kingdom |

| ECKA Granules | Germany |

| Toyal America Inc. | United States |

| Ampal Inc. | United States |

| Henan Yuanyang Powder Technology | China |

These companies produce pure aluminum powder in various particle size ranges using gas atomization, milling, and different production methods.

Pricing of Pure Aluminum Powder

Pricing of pure aluminum powder depends on:

- Purity – Higher purity (99.9%) powder is costlier than lower purity (99-99.5%)

- Particle Size – Finer aluminum powder is more expensive

- Morphology – Spherical and smooth powder costs more

- Coating – Uncoated aluminum powder is lower cost

- Quantity – Bulk quantities above 1 ton get discounted rates

- Supplier – Major companies have higher production output reducing costs

- Geography – Prices are competitive in China compared to Europe and USA

For small quantities, pure aluminum powder can cost between $50-100 per kg while bulk orders can be priced under $10/kg.

Health and Safety When Handling Aluminum Powder

Pure aluminum powder poses some health and safety hazards:

- Fine aluminum powder is highly flammable and explosive when suspended in air. Dust explosion risks must be mitigated.

- Oxidation is a risk leading to loss of material. Storage in inert atmosphere is recommended.

- Aluminum powder should not be heated or used near sparks or ignition sources.

- Contact with skin or eyes may cause irritation. Use personal protective equipment.

- Inhalation of fine aluminum powders may cause respiratory issues. Use appropriate ventilation and breathing protection.

- Aluminum powder wastage and disposal must be handled carefully to avoid contamination.

Inspection and Testing of Aluminum Powder

To ensure quality standards, pure aluminum powder is tested for:

- Chemical Composition – Inductively coupled plasma mass spectrometry and optical emission spectroscopy used to verify composition and purity.

- Particle Size – Laser diffraction analysis, sieve testing as per ASTM B214 standard used for measurement of particle size distribution.

- Morphology – Scanning electron microscopy used to examine shape and surface structure of powder particles.

- Flow Rate – Determined as per ASTM B213 using Hall flowmeter funnel. Spherical powder has excellent flowability.

- Apparent Density – Measured using gravimetric analysis or Scott volumeter as per ASTM B212.

- Specific Surface Area – BET gas absorption method used for measurement of surface area per unit mass, especially for nanoscale powders.

Routine testing ensures consistency in aluminum powder quality and performance.

Comparison of Atomized and Sintered Aluminum Powder

Atomized and sintered aluminum powders differ in production method and properties:

| Parameter | Atomized Al Powder | Sintered Al Powder |

|---|---|---|

| Production Method | Gas or water atomization of molten aluminum | Compacting and sintering of aluminum powder |

| Particle Morphology | Spherical | Irregular, porous |

| Particle Size | 5 to 150 microns | Under 5 microns |

| Flowability | Excellent | Poor |

| Purity | 99 to 99.9% | Lower |

| Cost | Higher | Lower |

| Applications | Thermal spray, AM | Flash powder, explosives |

Atomized aluminum powder has more controlled characteristics preferred for coatings, AM, electronics. Sintered aluminum is used where ultrafine particle size is required despite lower purity.

FAQs

Q: What is pure aluminum powder used for?

A: Pure aluminum powder is used in protective coatings, pyrotechnics, fuel additives, 3D printing, conductive inks, pigments, welding filler, and other applications requiring unalloyed aluminum properties.

Q: What is the difference between atomized and milled aluminum powder?

A: Atomized aluminum powder has spherical morphology and controlled particle size distribution while milled flake powder has irregular shapes and broader distribution. Atomized powder has better flow and packing density.

Q: How is ultrafine aluminum powder produced?

A: Special production methods like exploding wire process, evaporation-condensation, and high-energy ball milling allow production of aluminum powder with particle sizes below 10 microns.

Q: What safety precautions are needed when handling aluminum powder?

A: Fine aluminum powder is highly flammable. Dust explosion risks must be controlled. Storage in inert gas is recommended. Use proper grounding, ventilation, and PPE when handling aluminum powder.

Q: How is the purity of aluminum powder determined?

A: Spectroscopic analysis like ICP-MS and OES is used to accurately quantify the elemental composition. Purity levels from 99% to 99.9% based on impurity elements like iron, silicon are specified.

Q: Where can I buy pure aluminum powder for electronics applications?

A: High purity aluminum powder with controlled particle size and low impurities suitable for electronics can be purchased from suppliers like Valimet, Toyal America, Makin Metal powders, and ECKA Granules.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731