Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Some key properties and characteristics of 316L powder include:

Composition: Iron, chromium, nickel, molybdenum, manganese, silicon, carbon, phosphorus, sulfur

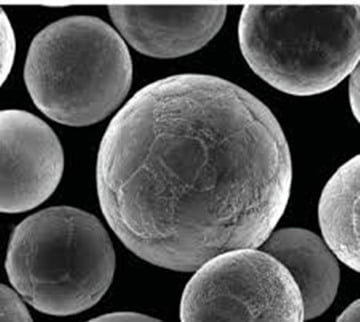

Particle Shape: Spherical, high flowability

Particle Size: 15-45 microns, submicron sizes available

Density: Approx 7.9 g/cc

Melting Point: 1381-1400°C

Key Features: Corrosion resistance, heat resistance, weldability, strength, biocompatibility

Common Trade Names: 316L, 1.4404, 1.4435

316L powder can be used to print strong and durable parts with complex geometries using various 3D printing processes like selective laser sintering (SLS), direct metal laser sintering (DMLS), electron beam melting (EBM), binder jetting, etc.

Types of 316L Powders

There are a few main types of 316L stainless steel powders available:

Gas Atomized 316L Powder

- Produced using inert gas atomization process

- Spherical particles with smooth surface

- Flows easily, packs densely for printing

- Good spreadability and compaction

- Used widely for laser-based and binder jet 3D printing

Water Atomized 316L Powder

- Made using high pressure water jets

- Irregular particle shape

- Porous surface, high oxygen content

- Lower cost compared to gas atomized powder

- Used mostly for press-and-sinter applications

Plasma Atomized 316L Powder

- Manufactured with plasma atomization

- Very spherical particles

- Controlled particle size distribution

- Used in critical applications requiring high density

- Expensive compared to other atomization methods

Recycled 316L Powder

- Recovered unused powder from 3D builds

- May have mixed particle shapes and sizes

- Needs additional sieving and processing

- Lower cost option for non-critical applications

- Concerns over contamination from prior builds

316L Powder Composition

316L stainless steel gets its corrosion resistance from chromium and molybdenum alloyed with iron. Here is the elemental composition of 316L powder:

| Element | Composition Range |

|---|---|

| Iron (Fe) | Balance |

| Chromium (Cr) | 16-18% |

| Nickel (Ni) | 10-14% |

| Molybdenum (Mo) | 2-3% |

| Manganese (Mn) | ≤ 2% |

| Silicon (Si) | ≤ 1% |

| Carbon (C) | ≤ 0.03% |

| Phosphorus (P) | ≤ 0.045% |

| Sulfur (S) | ≤ 0.03% |

The low carbon content reduces carbide precipitation during welding and enhances corrosion resistance. The addition of molybdenum boosts pitting and crevice corrosion performance in chloride environments.

The composition conforms to national and international grades like UNS S31603, W.Nr 1.4404, AISI 316L, and ISO 5832-1. Custom alloys are also possible for specialized requirements.

Key Properties and Characteristics

316L powder possesses a unique combination of outstanding properties which makes it suitable for various critical, high performance applications across industries.

Corrosion Resistance Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking in acids, alkalis, salts, and organic chemicals

Mechanical Properties High ultimate tensile and yield strength coupled with good ductility and impact strength

Heat Resistance Can withstand continuous service up to ~900°C and intermittent exposure beyond for certain applications

Weldability Readily weldable and less prone to sensitization during welding compared to unstabilized grades

Bio-compatibility Non-toxic with high biocompatibility for use in medical implants and devices

Here is a table comparing the key properties of 316 vs 316L powder:

| Property | 316 Powder | 316L Powder |

|---|---|---|

| Density (g/cc) | 7.9 | 7.9 |

| Melting Point (°C) | 1375-1400 | 1381-1400 |

| Ultimate Tensile Strength (MPa) | ≥ 515 | ≥ 485 |

| Yield Strength (MPa) | ≥ 170 | ≥ 170 |

| Elongation (%) | ≥ 40 | ≥ 35 |

| Modulus of Elasticity (GPa) | 193 | 193 |

| Thermal Conductivity (W/m-K) | 16.2 | 16.2 |

| Thermal Expansion (μm/m-°C) | 15-16.5 | 15-16.5 |

| Corrosion Resistance | Very Good | Excellent |

| Pitting Resistance Equivalency Number (PREN) | 24-26 | 25-27 |

| Magnetic Permeability | Non-magnetic | Non-magnetic |

| Bio-compatibility | Good | Excellent |

The superior corrosion resistance of 316L powder can be attributed to the higher PREN and lower carbon content compared to 316 powder. 316L also offers better bio-compatibility and is used preferentially for permanent implants in the human body.

Applications of 316L Powder

Some of the common applications where 316L powder finds widespread use include:

Additive Manufacturing SLS/DMLS/EBM printing of end-use metal parts across aerospace, medical, automotive, tooling etc.

Biomedical Implants Manufacturing implants like knee and hip replacements, spinal rods, dental fixtures etc.

Food Processing Equipment Valves, fittings, fasteners, machine parts for the food and pharmaceutical industries

Chemical Processing Industry

Pump impellers, housings, valve bodies and other wetted components

Marine Applications

Shafts, fittings, couplings, flanges, propellers used in marine environments

316L provides exceptional performance across this wide spectrum of applications owing to its outstanding corrosion resistance coupled with high strength.

Here are examples of some 316L parts printed using additive manufacturing:

| Industry | Typical AM Parts |

|---|---|

| Aerospace | Turbine blades, structural brackets, impellers |

| Automotive | Custom fasteners, sensors, lightweight chassis parts |

| Medical | Surgical instruments, prosthetics, implants |

| Tooling | Injection molds, extrusion dies, jigs and fixtures |

316L Powder Specifications

316L powder used for AM needs to conform to, or exceed, the following specifications:

Particle Size Distribution

| Size (μm) | Distribution (%) |

|---|---|

| 20-63 | ≥ 95 |

| 15-45 | Optimal |

Apparent Density Typically 4.0-4.8 g/cc

Flow Rate

Hall flowmeter > 15 sec/50g

Chemical Composition As per 316L grade specifications aforementioned

Microstructure

Fully austenitic, absence of stringers and satellites

Particle Shape Predominantly spherical morphology

Surface Texture Smooth surface finish on particles

Oxygen Content Mostly <1000 ppm

Saturation Magnetization < 3.1 emu/g

Reputable 316L powder manufacturers produce material that meets or surpasses these specifications for AM. Every batch comes with a Certificate of Analysis from independent testing.

316L Powder Suppliers

Some leading global suppliers of 316L stainless steel powder include:

| Company | Production Capacity | Cost Per KG |

|---|---|---|

| Sandvik Osprey | 200 MT annually | $50-90 |

| Carpenter Additive | Custom | $75-150 |

| Praxair | 100 MT annually | $40-80 |

| Höganäs | 500 MT annually | $30-60 |

| CNPC Powder | 1000 MT annually | $25-50 |

Custom alloys with special particle size distributions or tighter chemistry controls can cost 20-50% more than standard 316L powder compositions.

As for pricing, gas atomized 316L powder suitable for AM typically costs between $30-150 per kg depending on quality, batch size and geographic region. Water atomized and plasma atomized grades occupy the lower and upper ends of this range

Pros and Cons of 316L Powder for Additive Manufacturing

Advantages of 316L Powder

Excellent Corrosion Resistance Up to 25-30% better pitting and crevice corrosion resistance compared to 316 powder

Bio-compatible and Non-Toxic Safe for prolonged skin contact and for use in medical implants

High Mechanical Strength Tensile strength >485 MPa matching and exceeding cast/wrought 316L properties

Outstanding Fatigue Performance Very high fatigue limit resulting in long component lifespans

Lighter Weight Parts Lower component weight translates to fuel efficiency gains in vehicles

High Temperature Stability

Can resist temperatures exceeding 650°C for certain applications

Easy Weldability Compatible with almost all welding processes. Great for repairs and post-processing

Smoother Surfaces As-printed surfaces that require less finishing and rework

Cost-effectiveness Comparable in cost to 316 SS and cheaper than exotic alloys

Custom Alloys Possible Can engineer powder compositions tailored to a given application

Faster, Cheaper Prototyping No need for hard tooling like casting and machining dies

Disadvantages of Using 316L Powder for AM

Anisotropic Mechanical Behavior

Varies with build direction. Needs design and testing considerations.

Potential Internal Defects

Lack of fusion, un-melted particles, porosity. Depends on the AM process in use.

Post-Processing Needs Removal of supports, finish machining, annealing etc. can increase cost.

Limited Part Size Constrained by build chamber dimensions (improving constantly with new machines)

Orientation Constraints Some geometries need support structures and can limit design freedom

Property Variability

Powder reuse/recycle can result in inferior properties batch-to-batch

Surface Finish Limitations Can fluctuate more than traditional subtractive machining methods

Equipment and Material Cost High equipment investment. Large powder quantities needed for big parts.

Lack of Design Standards Rapidly evolving field. Continued qualification testing required.

Comparison Between 316L vs 17-4PH vs 15-5 PH Stainless Steel Powders

316L stainless steel powder has become the first choice for many additive manufacturing applications needing good mechanical performance coupled with high corrosion resistance. However, for more demanding applications, high strength structural powders like 17-4PH and 15-5 PH are being deployed with increasing use.

Here is how these stainless steel alloys compare for key powder properties relevant to AM:

| Powder Property | 316L SS | 17-4PH SS | 15-5 PH SS |

|---|---|---|---|

| Corrosion Resistance | Excellent | Moderate | Moderate |

| Tensile Strength | 485-550 MPa | 1050-1200 MPa | 1050-1150 MPa |

| Yield Strength | 170-340 MPa | 900-1100 MPa | 900-1000 MPa |

| Elongation | 35-50% | 8-13% | 10-16% |

| Fatigue Strength | 170-200 MPa | 500-700 MPa | 550-650 MPa |

| High Temperature Stability | Fair | Excellent | Excellent |

| Weldability | Excellent | Fair | Good |

| Cost Per Kg | $30-150 | $150-250 | $100-200 |

We can draw the following conclusions from this product comparison:

- For the highest corrosion resistance plus good weldability, 316L is unparalleled

- Where high strength outweighs corrosion performance, 17-4PH and 15-5 PH are better

- 17-4PH SS powder delivers the best high temperature creep resistance

- 15-5PH offers the optimal balance of strength and weldability/machinability

- 316L is the most cost-effective option while 17-4PH powder is relatively expensive

By carefully selecting the right grade for an application, buyers can obtain the ideal combination of properties and performance-to-cost ratio.

FAQs

Here are answers to some frequently asked questions regarding 316L stainless steel powder for AM processes:

Which additive manufacturing processes use 316L powder?

316L powder is compatible with all major direct metal AM processes that can print metals. These include:

- Powder bed fusion – SLS, DMLS, SLM

- Directed energy deposition – LENS, EBAM, laser cladding

- Bound metal deposition – Binder jetting

What are common 316L part defects in AM? How can they be avoided?

Some 316L part defects encountered include:

- Lack of fusion – Insufficient melting of powder. Increase laser power/speed

- Gas porosity – Optimize scan patterns. Use hot isostatic pressing

- Cracking – Modify support structures. Optimize thermal stresses

- Unmelted particles – Ensure uniform powder layers. Sieve properly.

What particle size is ideal for 316L powder in AM?

15-45 microns is recommended for most AM processes. Finer powder spreads better but can affect flow and recoating. Coarser particles have poor compactability.

What post-processing is typically done for 316L AM parts?

Post-processing steps help improve final part properties:

- Support removal via machining/grinding

- Hot isostatic pressing to eliminate internal voids

- Solution annealing and aging to refine microstructure

- Surface finishing like CNC machining and polishing

What standards does 316L powder for AM need to conform to?

While standards are still evolving, key ones include:

- ASTM F3049 – AM Metallic Powders

- ASTM F3056 – Characterizing AM Metal Powders

- ASTM F3301 – Properties for Additive Parts

- ISO/ASTM 52904 – Process parameters

Can 316L parts be welded or repaired after additive manufacturing?

Yes, 316L has very good weldability and AM-built components can be welded, repaired, and post-processed using techniques like TIG welding. Proper procedure development is vital for defect-free welds.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731