Titanium Ti6242 Powder

Titanium Ti6242 Powder is an alpha-beta titanium alloy with excellent strength, corrosion resistance, and high temperature performance. It is one of the most widely used titanium alloys and has applications in the aerospace, automotive, marine, chemical processing, and biomedical industries.

Advantages

- Excellent strength-to-weight ratio

- Good corrosion resistance

- Useful at moderate high temperatures

- Lower cost than Ti64 or Ti55531

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview

Titanium Ti6242 Powder is an alpha-beta titanium alloy with excellent strength, corrosion resistance, and high temperature performance. It is one of the most widely used titanium alloys and has applications in the aerospace, automotive, marine, chemical processing, and biomedical industries.

Some key properties and characteristics of Titanium Ti6242 powder:

Ti6242 Powder Composition

| Element | Weight % |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 6% |

| Vanadium (V) | 4% |

| Tin (Sn) | 2% |

| Zirconium (Zr) | 2% |

Ti6242 Powder Properties

| Property | Description |

|---|---|

| Strength | Excellent strength comparable to steel alloys |

| Hardness | 36 HRC after aging heat treatment |

| Corrosion Resistance | Resistant to most acids, chloride environments |

| High Temperature Performance | Useful up to approx. 550°C in air |

| Density | 4.43 g/cc |

| Particle Size | 15-45 microns |

Ti6242 Powder Characteristics

| Characteristic | Details |

|---|---|

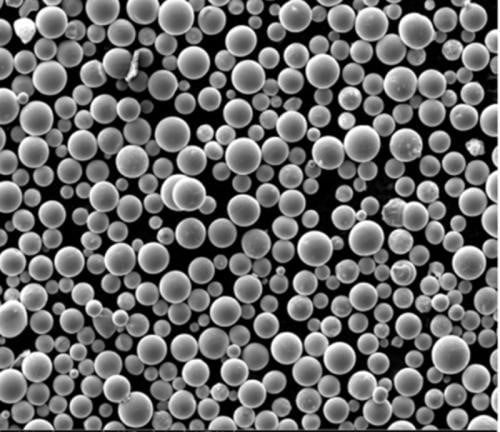

| Manufacturing Process | Gas atomization process |

| Morphology | Spherical powder particles |

| Flowability | Good due to spherical shape |

| Apparent Density | 2.5-3.0 g/cc |

| Tap Density | 3.5-4.0 g/cc |

Applications of Ti6242 Powder

Some of the major applications of Ti6242 powder include:

Aerospace Applications

- Engine components like blades, discs, spacers

- Airframe parts and structures

- Fasteners, hydraulic tubing

Benefits

- High strength-to-weight ratio

- Withstand high temperatures and stresses

- Corrosion resistance

Automotive Applications

- Valve springs, valve lifters, connecting rods

- Motor sports components

Benefits

- Reduce weight of moving components

- Withstand under-hood temperatures

- High fatigue strength

Chemical Processing Industry

- Heat exchangers, reaction vessels

- Pumps, valves, pipes and fittings

Benefits

- Excellent corrosion resistance to acids, chlorides

- Withstand high pressure and temperatures

Biomedical Industry

- Surgical instruments, implants

- Orthopedic devices

Benefits

- Biocompatibility

- Withstand sterilization

- High fatigue strength

Comparison of Ti6242 vs. Other Titanium Alloys

| Alloy | Strength | Corrosion Resistance | High Temperature Capability | Cost |

|---|---|---|---|---|

| Ti6242 | Excellent | Excellent | Good | Moderate |

| Ti64 | Excellent | Moderate | Excellent | High |

| Ti55531 | Excellent | Excellent | Moderate | Very High |

Specifications and Standards

Ti6242 conforms to the following specifications and standards:

| Standard | Details |

|---|---|

| AMS 4928 | Aerospace Material Specification issued by SAE |

| ISO 5832-11 | International specifications for surgical implant applications |

| ASTM F3001 | Specification for Additive Manufacturing with powder bed fusion |

| ASTM B348 | Specification for Titanium and Titanium Alloy Powders |

Ti6242 Powder Sizes Available

| Size | Details | Applications |

|---|---|---|

| 15-45 microns | Fine powder size | AM, HIP |

| 45-106 microns | Coarse powder size | Press & Sinter |

Suppliers and Pricing

Some leading global suppliers of Ti6242 powder include:

Ti6242 Powder Suppliers

| Supplier | Location |

|---|---|

| AP&C | Canada |

| Carpenter Additive | United States |

| GKN Hoeganaes | Europe |

| Praxair | United States |

Ti6242 Powder Pricing

| Powder Grade | Particle Size | Price ($/kg) |

|---|---|---|

| Grade 23 | 15-45 microns | $75-100 |

| Grade 23 | 45-106 microns | $50-75 |

| Grade 5 | 15-45 microns | $100-150 |

Prices depend on order volume, particle size distribution, chemistry tolerances.

Pros and Cons of Using Ti6242 Powder

Advantages

- Excellent strength-to-weight ratio

- Good corrosion resistance

- Useful at moderate high temperatures

- Lower cost than Ti64 or Ti55531

Disadvantages

- Not as heat resistant as nickel alloys

- Difficult to machine in fully hardened state

- Susceptible to galling without surface treatment

- Higher cost than steels

FAQs

What are the contents of Ti6242 alloy?

Ti6242 contains 6% aluminum, 4% vanadium, 2% tin and 2% zirconium, balance titanium. This composition provides an excellent combination of strength, toughness and corrosion resistance.

What heat treatment is used for Ti6242?

A typical heat treatment is to solution treat at 955°C, followed by aging at 595°C to achieve optimum strength. This results in a microstructure containing alpha and beta phases.

What is the tensile strength of Ti6242?

Tensile strength of wrought Ti6242 is around 130,000 psi (900 MPa) in the annealed state. After heat treatment, it can reach around 160,000 psi (1100 MPa).

What is the density of Ti6242 titanium alloy?

The density of Ti6242 is 4.43 g/cc, which falls between steel and aluminum alloys. This provides an excellent strength-to-weight ratio.

What is the difference between Grade 5 and Grade 23 Ti6242 powder?

Grade 5 powder has lower interstitial element levels (especially oxygen and nitrogen) than Grade 23, making it preferred for critical applications, but it comes at a higher cost.

What standards does Ti6242 powder conform to?

Key titanium powder standards are ASTM B348, AMS 4999, ISO 5832-3, ASTM F3049, ASTM F3001. These cover chemistry, particle size distribution, morphology, flow characteristics etc.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731