Titanium Powder Suppliers

Table of Contents

Titanium powder is a versatile metal powder with unique properties that make it an important material for many applications. This article provides an overview of titanium powder, its properties, production methods, applications, and leading global suppliers.

Overview of Titanium Powder

Titanium powder is composed of fine titanium particles used to manufacture parts, coatings, and additives. Key properties include:

- High strength-to-weight ratio

- Corrosion resistance

- Biocompatibility

- High melting point

- Low density

- Strength retention at high temperatures

Titanium powder is available in various purity grades, particle sizes, and morphologies to suit different production processes and end-use requirements.

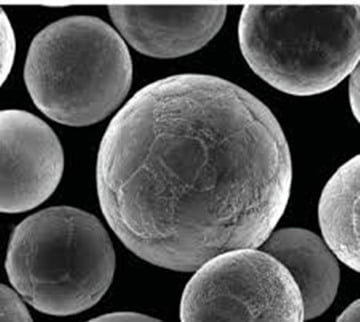

The most common production methods for titanium powder are gas atomization and plasma spheroidization. Suppliers offer both crude titanium powders as well as spheroidized, alloyed and plasma purified grades.

Titanium Powder Types

| Type | Description | Applications |

|---|---|---|

| Pure Titanium | 99.5-99.9% titanium content | Aerospace, medical, consumer products |

| Ti-6Al-4V | Titanium + 6% aluminum + 4% vanadium | Aerospace, automotive, implants |

| Ti64 | An alternative designation for Ti-6Al-4V | Aerospace, automotive, implants |

| Ti-6Al-7Nb | Titanium + 6% aluminum + 7% niobium | Aerospace, medical |

| Other Titanium Alloys | Various compositions possible | Specialty applications |

Titanium Powder Characteristics

| Characteristic | Details | Significance |

|---|---|---|

| Particle Size | Range from 10-250 microns | Determines suitability for additive manufacturing or pressing applications |

| Morphology | May be irregular, angular, or spheroidal | Spheroidal powders have better flowability |

| Purity | Grades from CP1 to CP4 based on oxygen, nitrogen, carbon levels | Higher purity grades required for more demanding applications |

| Alloy Composition | Varies based on aluminum, vanadium, other alloying content | Alloying elements enhance strength and modify properties |

| Production Method | Gas atomized, plasma purified, hydride-dehydride | Affects particle characteristics like size distribution, shape, purity |

Titanium Powder Specifications

| Parameter | Range |

|---|---|

| Particle size | 10-150 microns typical |

| Oxygen content | <0.20% for Grade 1 titanium |

| Nitrogen content | <0.03% for Grade 1 titanium |

| Carbon content | <0.08% for Grade 1 titanium |

| Tap density | 2.2-3.8 g/cc |

| Apparent density | >92% of absolute density |

Applications of Titanium Powder

| Industry | Application | Properties Leveraged | Advantages | Challenges |

|---|---|---|---|---|

| Aerospace | – Aircraft fuselages and wings – Landing gear components – Engine parts (compressor blades, discs) | High strength-to-weight ratio, Excellent fatigue resistance, Corrosion resistance | – Lighter aircraft for increased fuel efficiency and range – Improved performance and durability in harsh environments | – High cost of titanium powder – Requires specialized equipment and expertise for additive manufacturing |

| Automotive | – High-performance connecting rods – Lightweight suspension components – Braking systems | High strength-to-weight ratio, Good wear resistance | – Enhanced vehicle handling and fuel economy – Reduced weight for overall performance gains | – Needs for post-processing techniques to achieve desired surface finish – Limited production volumes due to cost considerations |

| Medical & Dental | – Implants (knee, hip, dental) – Prosthetic limbs and cranial implants | Biocompatibility, Osseointegration (ability to bond with bone), Corrosion resistance | – Improved patient outcomes and long-term implant success – Biocompatible material minimizes rejection risks | – Stringent regulatory requirements for biocompatibility testing – Potential for high costs associated with implants |

| Consumer Goods | – High-end bicycles and sporting goods – Luxury watches and jewelry | High strength-to-weight ratio, Corrosion resistance, Aesthetic appeal | – Products with exceptional strength and durability – Lightweight design for comfort and performance | – Limited applications due to high cost – Potential safety concerns if not properly manufactured |

| Additive Manufacturing | – Complex, near-net-shape components across various industries | Design flexibility, Material efficiency, Reduced waste | – Enables creation of intricate designs not possible with traditional methods – Minimizes material waste compared to subtractive manufacturing | – Requires careful powder selection and process control for optimal results – Potential for surface roughness depending on the printing technique |

| Emerging Applications | – Biomedical scaffolds for tissue engineering – Filtration membranes – Chemical processing equipment | Biocompatibility, Corrosion resistance, High strength | – Potential for advancements in regenerative medicine – Efficient filtration with excellent durability – Lightweight and corrosion-resistant equipment for harsh environments | – Research and development stage for some applications – Scalability and cost reduction needed for wider adoption |

Global Titanium Powder Suppliers

| Supplier | Headquarters | Annual Production Capacity (Tonnes) | Production Methods | Key Products | Applications | Certifications |

|---|---|---|---|---|---|---|

| ATI Powder Metals (US) | Ormstown, Quebec, Canada | 5,000 | Hydride-dehydride (HDH) | CP Titanium, Ti-6Al-4V, Ti-6Al-7Nb | Additive Manufacturing, Metal Injection Molding, Powder Metallurgy | AS9100, ISO 9001, Nadcap |

| AP&C (Canada) | Montreal, Quebec, Canada | 75,000 | HDH | CP Titanium, near-spherical titanium powders, Titanium alloys (Ti-6Al-4V, Ti-6Al-7Nb) | Additive Manufacturing, Metal Injection Molding, Powder Metallurgy | AS9100, ISO 9001, Nadcap |

| Dow Titanium (US/Europe) | Midland, Michigan, US & Chateaubriand, France | 30,000 | Sodium reduction, HDH | CP Titanium, Titanium alloys (Ti-6Al-4V, Ti-4Al-3Mo-1V) | Additive Manufacturing, Metal Injection Molding, Powder Metallurgy | AS9100, ISO 9001, Nadcap |

| Norsk Titanium (Norway) | Kristiansand, Norway | 4,500 | Plasma Atomization | CP Titanium, Titanium alloys (Ti-6Al-4V, Ti-5Al-2.5Sn) | Additive Manufacturing, Aerospace components | AS9100, ISO 9001, Nadcap |

| OSAKA Titanium Technologies (Japan) | Osaka, Japan | 5,000 | HDH, Electron Beam Melting | CP Titanium, Titanium alloys (Ti-6Al-4V, Ti-17) | Additive Manufacturing, Medical implants | ISO 9001 |

| Praxair Surface Technologies ( Francji) | Saint-Priest, France | 2,000 | Plasma Atomization | Titanium alloys (Ti-6Al-4V, Ti-2Al-4Nb) | Additive Manufacturing, Thermal Spray Coatings | AS9100, ISO 9001 |

| Schunk Group (Germany) | Heuchelheim, Germany | 1,200 | Gas Atomization | Titanium alloys (Ti-6Al-4V, Ti-2Al-4Nb) | Additive Manufacturing, Medical implants | ISO 9001, ISO 13485 |

| Shaanxi TMT Titanium Industry Co. Ltd (China) | Baoji, China | Capacity undisclosed | Various methods (HDH, Plasma Atomization) | CP Titanium, Titanium alloys | Aerospace, Chemical Processing Equipment | AS9100, ISO 9001 |

| Sumitomo Metal Industries Ltd (Japan) | Osaka, Japan | Capacity undisclosed | Sponge Crush & Milling | CP Titanium, Titanium alloys | Powder Metallurgy | ISO 9001 |

| Tekna (Canada) | Sherbrooke, Quebec, Canada | 1,000 | Plasma Atomization | CP Titanium, Titanium alloys (Ti-6Al-4V, Ti-6Al-7Nb) | Additive Manufacturing, Medical implants | AS9100, ISO 9001, Nadcap |

Titanium vs. Alternative Powders

| Feature | Titanium | Alternative Powders |

|---|---|---|

| Mechanical Properties | Excellent strength-to-weight ratio, high fatigue strength, good corrosion resistance | Properties vary depending on the material. Examples: Stainless steel offers good strength and corrosion resistance, but heavier than titanium; Aluminum offers lightweight properties but with lower strength; Nickel alloys boast high-temperature performance but can be expensive. |

| Biocompatibility | Non-toxic and biocompatible, ideal for medical implants | Biocompatibility varies. Stainless steel is generally biocompatible for some implants, but some grades may require additional surface treatments. Aluminum is not biocompatible and can corrode in the body. Nickel alloys can be biocompatible but some grades may cause allergic reactions. |

| Powder Characteristics | High melting point requires specialized printing techniques, flowability can be an issue for some powder types | Melting points vary. Steel and nickel alloys often have lower melting points than titanium, making them easier to print. However, these powders can be more susceptible to oxidation during printing. Aluminum powders are highly reactive and require inert printing environments. |

| Cost | Relatively expensive due to complex production processes | Costs vary depending on the material. Steel powders are generally cheaper than titanium, while aluminum powders are even more affordable. Nickel alloys can be quite expensive, depending on the specific composition. |

| Applications | Aerospace, biomedical, automotive, sporting goods (due to its high strength-to-weight ratio) | Diverse applications depending on the material. Stainless steel is widely used in various industries due to its good balance of properties. Aluminum is common in aerospace and automotive applications due to its lightweight nature. Nickel alloys are used in high-temperature environments like jet engines and power plants. |

Choosing a Titanium Powder Supplier

Key factors in choosing a titanium powder supplier:

| Consideration | Details to Explore | Impact on Your Project |

|---|---|---|

| Powder Properties | * Grade: CP (Commercially Pure) Titanium or Titanium Alloys (e.g., Ti-6Al-4V, Ti-6Al-7Nb) * Particle Size & Distribution: Affects flowability, density, and printability. * Morphology: Spherical shapes offer better flow and packing. * Chemistry & Impurity Levels: Oxygen, nitrogen, and carbon content significantly impact mechanical properties. | Directly influences the final product’s strength, corrosion resistance, biocompatibility, and printability. Mismatched properties can lead to part failure. |

| Supplier Capabilities | * Production Method: Gas Atomization (GA) or Plasma Atomization (PA) significantly affect powder quality. * Quality Control & Certifications: Look for AS9100 or ISO 13485 for aerospace or medical applications. * Custom Powder Development: Ability to tailor properties for specific needs. * Minimum Order Quantity (MOQ): Ensure alignment with your production volume. | Supplier’s expertise and certifications ensure consistent, high-quality powder that meets industry standards. Customization allows for optimized performance. |

| Technical Support & Service | * Material Data Sheets (MDS): Detailed information on chemical composition, particle size distribution, and mechanical properties. * Application Expertise: Supplier’s knowledge of your specific application (e.g., AM, Powder Metallurgy) is crucial. * After-Sales Support: Troubleshooting assistance and technical guidance are valuable resources. | Access to comprehensive data and supplier knowledge empowers informed decision-making and successful project execution. |

| Pricing & Lead Times | * Cost per Kilogram (kg): Consider total project cost, not just upfront material price. * Volume Discounts: Negotiate for larger orders. * Lead Times: Production capacity and delivery timelines should align with your project schedule. | Striking a balance between cost, availability, and timeliness is essential for project budget and production flow. |

| Supplier Reputation & Reliability | * Industry Recognition & References: Positive reputation and proven track record with similar projects inspire confidence. * Financial Stability: Supplier’s financial health ensures long-term supply chain security. * Environmental & Safety Practices: Alignment with your company’s sustainability goals is a plus. | Choosing a reputable and reliable supplier minimizes risks associated with product quality, delivery delays, and potential disruptions. |

FAQ

Q: What is the difference between commercially pure titanium vs titanium alloy powder?

A: Commercially pure titanium powder has 99.5-99.9% titanium content with low oxygen, nitrogen and carbon. Titanium alloy powders like Ti-6Al-4V contain aluminum, vanadium, or other elements to enhance properties like strength.

Q: What particle size titanium powder is optimal?

A: For pressing and sintering 75-150 microns is common. For additive manufacturing processes, finer 15-45 micron powder is preferred to achieve good resolution.

Q: Does titanium powder require special handling precautions?

A: Yes, titanium fines are flammable and create explosion hazard. Inert gas blanketing and proper grounding is used. Water contact causes hydrogen absorption issues.

Q: How to determine which titanium grade is best for my application?

A: Consult closely with potential suppliers on technical requirements. Ti-6Al-4V is the most common grade but others like Ti-6Al-7Nb suit specific needs. Get test samples to evaluate performance.

Q: What methods can produce titanium powder suitable for 3D printing?

A: Gas atomization and plasma spheroidization create fine spherical titanium powders optimal for additive manufacturing. Hydride-dehydride and mechanical milling methods also produce printable powder.

Q: What post-processing is required on additively manufactured titanium parts?

A: Hot isostatic pressing (HIP) helps eliminate porosity in printed parts. Additional heat treatments, surface finishing, and machining may be needed depending on final properties and tolerances required.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731