Metal Powders for 3D Printing and Additive Manufacturing

Discover the most advanced 3D printing metal powder solutions! We offer industry-leading metal powders to meet your various 3D printing needs.

With decades of collective expertise.

WHO WE ARE

A Company of Excellent Services

Metal3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. The company specializes in 3D printing metal powder for industrial applications.

Organized & Certificated

At Metal3DP, organization and certification are the cornerstones of our commitment to delivering excellence in the field of additive manufacturing.

Precision Through Organization

Our structured approach ensures meticulous control at every step of additive manufacturing, delivering top-tier quality from design to production.

ISO 9001 Certified

With ISO 9001 certification, we validate our commitment to superior quality management, ensuring customer satisfaction and continuous enhancement.

SERVICES

Manufacturing at its Best

Advanced 3D Printing Solutions

Cutting-edge solutions using SLS, SLM, and SEBM technologies.

Custom Metal Powders

Tailored materials for specific project needs.

Application Development

Comprehensive support from prototyping to production.

Digital Manufacturing Partner

Guiding organizations through digital transformations.

Products

Metal Powders for 3D Printing and Additive Manufacturing

-

AlMgScZr Powder

-

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

-

CoCrMoW Powder

-

Nickel-based K403 Powder

-

AlSi10Mg powder for SLM EBM 3D Printing

-

Ti22Al25Nb Powder

-

Titanium and aluminum TA7 powder

-

Best 17-4PH stainless steel powder for 3D Printing

-

Best IN738LC powder for 3D printing in 2025

-

Best in718 powder inconel 718 powder for metal 3D printing

-

Best Hastelloy X Powder丨High temperature alloy Powder for 3D Printing

-

Inconel 625 Powder丨Nickel based superalloy in625 powder

Delivering Excellent

Our Technology and Craftsmanship

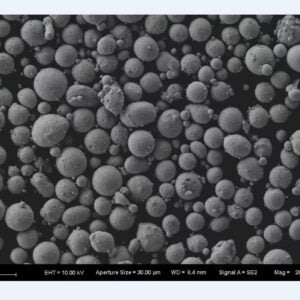

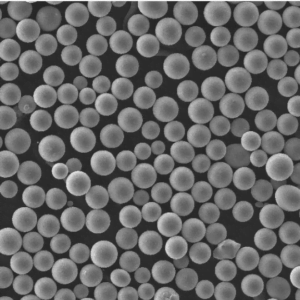

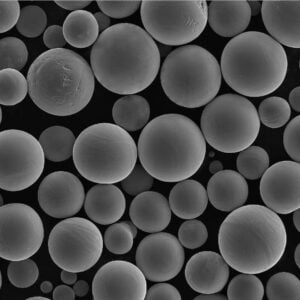

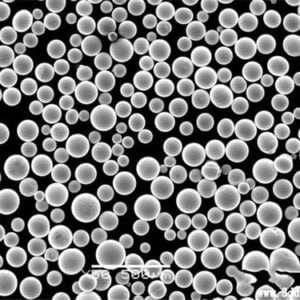

We utilize state-of-the-art technology to produce high-quality 3d printing metal powders with uniform size and excellent surface quality, using techniques such as laser and plasma technology.

Our Technology 01.

advanced metal powder

We offer industry-leading metal powders to meet your various 3D printing needs. Whether it’s aerospace, medical, automotive, or industrial manufacturing, we have the right metallic materials.

Our Technology 02.

Various production processes

As a leading producer of high-quality 3D printing metal powder, our company utilizes advanced production processes including plasma rotating electrode process and plasma atomization.

Our Technology 03.

Customization powders

We can customize various types of special 3d printing metal powders according to customer needs, ensuring that everything from materials to finished products meets customer requirements and ensures technological leadership.

Our Technology 04.

Technical support from experts

In addition to state-of-the-art production facilities, our company also provides unparalleled technical support to deliver customized 3D printing solutions. Our team of industry experts offers specialized consultation to understand each client’s unique requirements and challenges.

Our Technology 05.

Materials Engineering Expertise

Our materials experts work hard to develop innovative alloys like TiNi, TiTa, TiAl, TiNbZr, CoCrMo, stainless steel superalloys, and other 3d printing metal powder, engineered to meet demanding industry performance standards.

15,000 ㎡

Specialized Plant Area

Our factory has sufficient production space and equipment support.

15

Production Lines

We have a number of production lines operated by experienced professionals.

100,000

Products Capacity

With modern equipment and technology, we can meet the needs of large volume orders.

600 +

Trusted Customers

We work with many global brands and are trusted and well received.

WHY US

Precision in Every Print.

Quality in Every Grain.

Advanced Techniques Mastery

With unparalleled expertise in SLS, SLM, and SEBM techniques, Metal3DP ensures precision and quality in every print.

State-of-the-Art Equipment

Our industry-leading printer capabilities allow for intricate designs, large build volumes, and exceptional reliability, catering to a wide range of applications.

High-Quality Materials

We offer a premium range of metal powders, optimized for both laser and electron beam powder bed fusion, ensuring dense, top-quality metal parts with superior mechanical performance.

Client-Centric Approach

Our collaborative approach ensures that we work closely with clients, understanding their needs and providing tailored solutions that drive results.

Innovation at Core

Always ahead in technology and research, Metal3DP is committed to pushing the boundaries of additive manufacturing, offering the latest advancements to our clients.

End-to-End Support

From initial consultation to post-sales assistance, Metal3DP's dedicated team offers comprehensive support, ensuring a seamless experience and the successful implementation of our solutions in your operations.

Awesome Features

Our Highlight Advantages

Met3DP has professional R&D and management team, strictly follows the international test standards of CE, ISO9000.

Specialize in Metal Powders for 3D Printing and Additive Manufacturing

We firmly believe that delivering high-quality products promptly is the key to forging long-term collaborations. Your satisfaction is the driving force behind our ongoing progress in the world of metal additive manufacturing.

Choose Met3DP, where quality assurance and global accessibility combine to earn your trust and fuel our progress. Your confidence in our solutions is our ultimate goal.

- Direct To Factory

- Services Worldwide

- Rich Industry Experience

- Advance Management Method

- Excellent Service

- Outstanding Quality

Unlocking Possibilities

Discover Metal3DP’s Diverse Industry Applications

At Metal3DP, we’re not just about metal powders; we’re about transforming industries through innovation.

HIP Technology

Hot Isostatic Pressing (HIP) technology works by placing the product in a closed container…

MIM Technology

MIM products can be complex in shape, precise in size, high in strength and produced…

SLM Technology

SLM is similar in principle to SLS in that a laser is used to melt and solidify metal powder…

EBM Technology

EBM refers to a vacuum melting method in which the kinetic energy of a high speed stream…

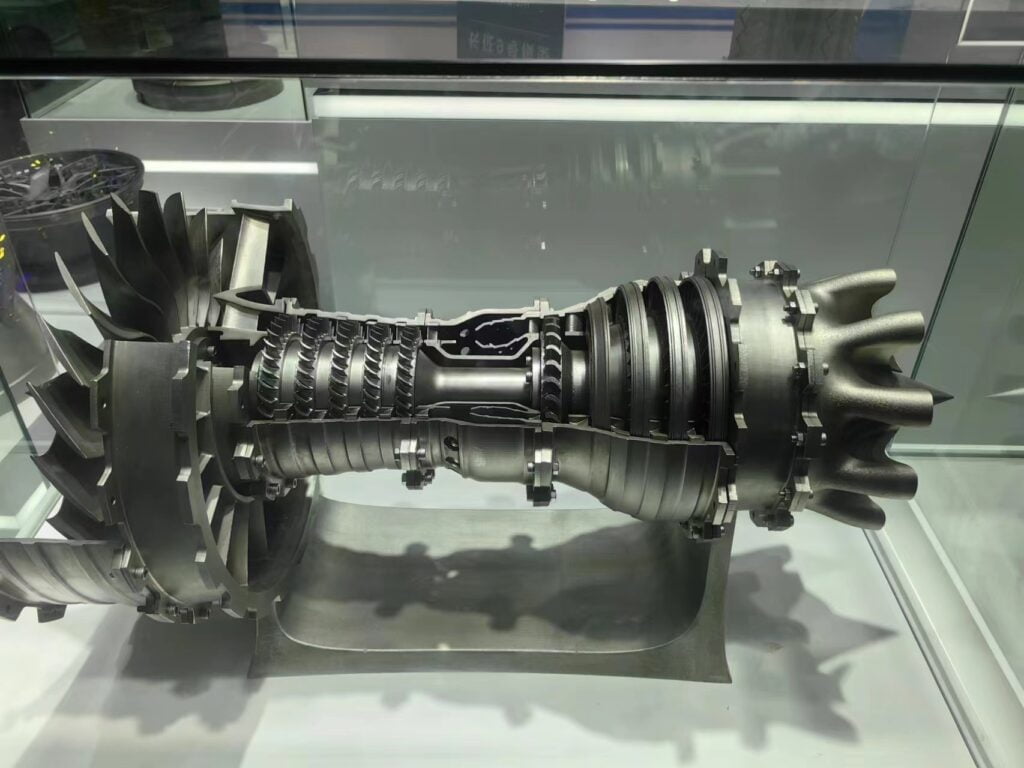

Projects

Projects We Finished

Each project represents a unique fusion of innovation, precision, and cutting-edge technology, providing solutions that meet the most demanding industry requirements.

Custom wheels

Transform wheel designs into high-performance masterpieces that redefine automotive aesthetics and performance.

Custom Jewelry

Blending precision and artistic vision to create one-of-a-kind pieces that embody craftsmanship and personalization.

Aerospace Parts

Witness innovations in producing complex, high-precision parts that meet the exacting requirements of the aerospace industry.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731