Aluminum Based Alloy Powder

Product Category

Al 2024 powder

Al 2024 powder is an aluminum alloy that primarily consists of aluminum, copper, and small amounts of magnesium and manganese. This alloy exhibits exceptional strength and excellent fatigue resistance, making it ideal for applications where lightweight materials with high mechanical properties are required. Al 2024 powder is commonly used in industries such as aerospace, automotive, and sporting goods.

Al 3003 powder

Al 3003 powder is an aluminum alloy powder composed mainly of aluminum and manganese. It belongs to the 3xxx series of aluminum alloys, which are known for their excellent workability and corrosion resistance. The powder form allows for easy handling and processing, making it suitable for various manufacturing techniques.

Al 3004 powder

Al 3004 powder is a specially formulated coating material composed of aluminum alloy. It is created by combining aluminum with a precise blend of alloying elements to ensure optimal performance. The powder form allows for easy application and provides a uniform coating when properly cured.

Al 3103 powder

Al 3103 powder is a form of aluminum alloy that exhibits excellent mechanical properties, corrosion resistance, and thermal conductivity. It belongs to the 3xxx series of aluminum alloys, which are known for their moderate strength and exceptional formability. The powder form allows for easier handling, processing, and fabrication, making it suitable for various industrial applications.

Al 3104 powder

Al 3104 powder is an aluminum alloy composed primarily of aluminum (Al) with small additions of manganese (Mn) and magnesium (Mg). This powder form of the alloy offers distinct advantages in terms of its processability and versatility. It is commonly used in various industries due to its excellent combination of strength, corrosion resistance, and formability.

Al 3203 powder

Al2O3 powder is an aluminum alloy composed of aluminum, copper, and manganese. It is renowned for its excellent strength and high fatigue resistance, making it an ideal choice for demanding environments and structural components. The precise composition and manufacturing process of Al 3203 powder ensure consistent quality and performance, making it a reliable material for numerous applications.

Al 6061 powder for additive manufacturing (AM)

Al 6061 powder is a versatile aluminum material composed of various elements to enhance its properties, such as strength, corrosion resistance, and machinability. It is widely used in different industries for its excellent characteristics.

Al 7075 powder

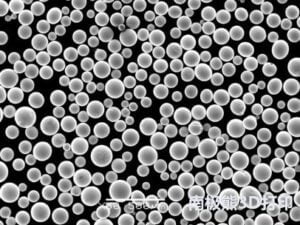

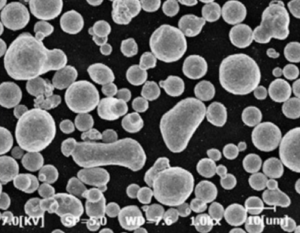

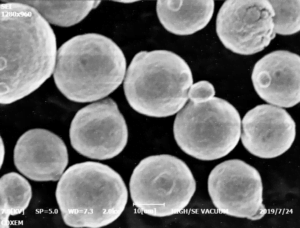

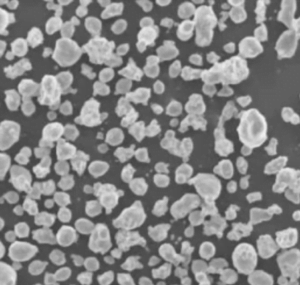

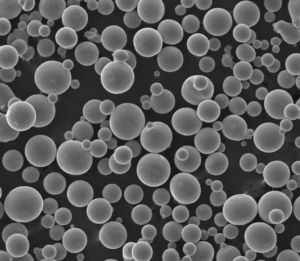

Al 7075 powder is a high-strength aluminum alloy composed primarily of aluminum, zinc, copper, and small amounts of magnesium and chromium. It is renowned for its impressive mechanical properties, making it an ideal choice for applications that require strength, durability, and lightweight characteristics. Al 7075 powder is typically produced through a process called atomization, where molten aluminum is sprayed and solidified into fine powder particles.

AlMgScZr Powder

AlMgScZr powder is an aluminum alloy containing magnesium, scandium and zirconium as the main alloying elements. It exhibits excellent strength, weldability and corrosion resistance while maintaining the low density advantage of aluminum.

AlSi10 Powder

AlSi10 is an aluminum alloy powder containing 10% silicon and remainder aluminum. It offers an excellent combination of strength, low density, thermal properties, corrosion resistance and weldability.

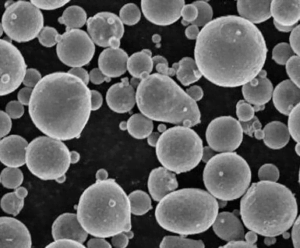

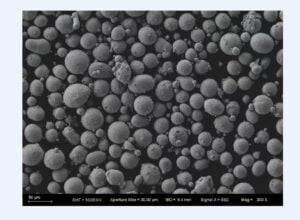

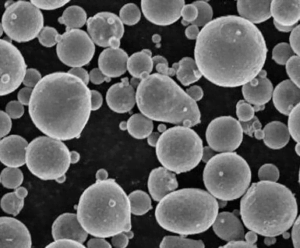

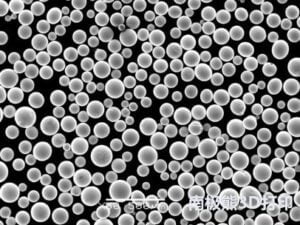

AlSi10Mg powder for SLM EBM 3D Printing

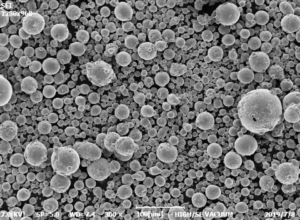

AlSi10Mg powder is a composite material composed of aluminum (Al), silicon (Si), and magnesium (Mg). It is specifically designed for use in additive manufacturing processes, where it is used as a feedstock material for 3D printers.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| AlSi10Mg | 15-45μm | 1KG | 70 | 15-53μm | 1KG | 51 |

| 10KG | 42 | 10KG | 33 | |||

| 100KG | 34.6 | 100KG | 23.5 |

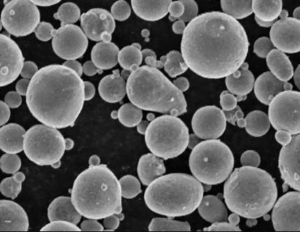

AlSi12 Powder

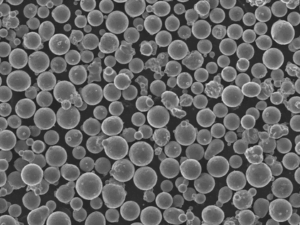

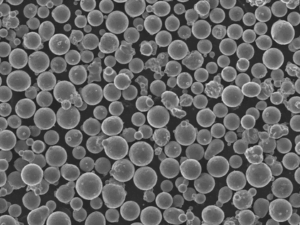

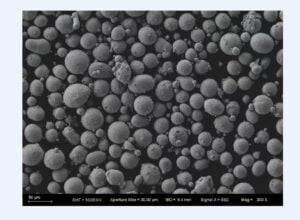

AlSi12 powder is a fine-grained aluminum-silicon alloy powder commonly used in additive manufacturing processes. It is produced by atomization, which involves melting the alloy and rapidly cooling it to form small powder particles. The resulting powder exhibits excellent flowability and can be easily processed using various additive manufacturing techniques such as selective laser melting (SLM) and electron beam melting (EBM).

AlSi50 Powder

AlSi50 is an aluminum-silicon alloy powder containing 50% silicon and remainder aluminum. It offers an exceptional combination of properties like low density, high fluidity, low thermal expansion, high specific strength, and corrosion resistance.

AlSi7Mg powder

AlSi7Mg powder is an aluminum alloy powder that primarily consists of aluminum (Al), silicon (Si), and magnesium (Mg). The “7” in its name signifies the percentage of silicon, while “Mg” represents the magnesium content. This powder exhibits excellent strength, low density, and impressive thermal properties, making it a preferred choice in multiple industries.

AlSiCu Powder(AlSi10)

AlSi10 is an aluminum alloy powder containing 10% silicon and remainder aluminum. It offers an excellent combination of strength, low density, thermal properties, corrosion resistance and weldability.

AlSiMg Powder

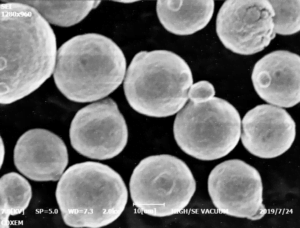

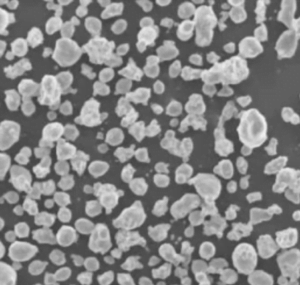

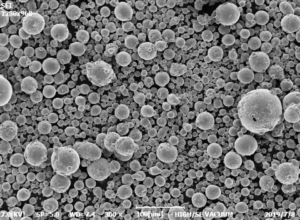

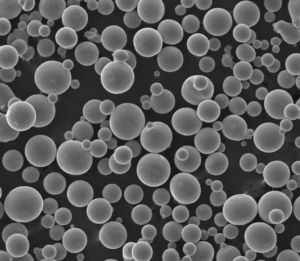

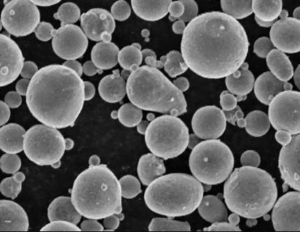

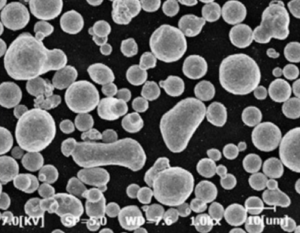

Our company’s gas atomized AlSiMg powder, good sphericity, low oxygen content, good fluidity.at present, aluminum alloys used in metal 3D printing mainly include AlSi12 and AlSi10Mg,they are lightweight additive metal powders with good thermal properties. It can be applied to thin-wall parts such as heat exchangers and other automotive parts, and also can be applied to aerospace and aerospace industrial grade prototype and production parts.

Al 2024 powder

Al 2024 powder is an aluminum alloy that primarily consists of aluminum, copper, and small amounts of magnesium and manganese. This alloy exhibits exceptional strength and excellent fatigue resistance, making it ideal for applications where lightweight materials with high mechanical properties are required. Al 2024 powder is commonly used in industries such as aerospace, automotive, and sporting goods.

Al 3003 powder

Al 3003 powder is an aluminum alloy powder composed mainly of aluminum and manganese. It belongs to the 3xxx series of aluminum alloys, which are known for their excellent workability and corrosion resistance. The powder form allows for easy handling and processing, making it suitable for various manufacturing techniques.

Al 3004 powder

Al 3004 powder is a specially formulated coating material composed of aluminum alloy. It is created by combining aluminum with a precise blend of alloying elements to ensure optimal performance. The powder form allows for easy application and provides a uniform coating when properly cured.

Al 3103 powder

Al 3103 powder is a form of aluminum alloy that exhibits excellent mechanical properties, corrosion resistance, and thermal conductivity. It belongs to the 3xxx series of aluminum alloys, which are known for their moderate strength and exceptional formability. The powder form allows for easier handling, processing, and fabrication, making it suitable for various industrial applications.

Al 3104 powder

Al 3104 powder is an aluminum alloy composed primarily of aluminum (Al) with small additions of manganese (Mn) and magnesium (Mg). This powder form of the alloy offers distinct advantages in terms of its processability and versatility. It is commonly used in various industries due to its excellent combination of strength, corrosion resistance, and formability.

Al 3203 powder

Al2O3 powder is an aluminum alloy composed of aluminum, copper, and manganese. It is renowned for its excellent strength and high fatigue resistance, making it an ideal choice for demanding environments and structural components. The precise composition and manufacturing process of Al 3203 powder ensure consistent quality and performance, making it a reliable material for numerous applications.

Al 6061 powder for additive manufacturing (AM)

Al 6061 powder is a versatile aluminum material composed of various elements to enhance its properties, such as strength, corrosion resistance, and machinability. It is widely used in different industries for its excellent characteristics.

Al 7075 powder

Al 7075 powder is a high-strength aluminum alloy composed primarily of aluminum, zinc, copper, and small amounts of magnesium and chromium. It is renowned for its impressive mechanical properties, making it an ideal choice for applications that require strength, durability, and lightweight characteristics. Al 7075 powder is typically produced through a process called atomization, where molten aluminum is sprayed and solidified into fine powder particles.

AlMgScZr Powder

AlMgScZr powder is an aluminum alloy containing magnesium, scandium and zirconium as the main alloying elements. It exhibits excellent strength, weldability and corrosion resistance while maintaining the low density advantage of aluminum.

AlSi10 Powder

AlSi10 is an aluminum alloy powder containing 10% silicon and remainder aluminum. It offers an excellent combination of strength, low density, thermal properties, corrosion resistance and weldability.

AlSi10Mg powder for SLM EBM 3D Printing

AlSi10Mg powder is a composite material composed of aluminum (Al), silicon (Si), and magnesium (Mg). It is specifically designed for use in additive manufacturing processes, where it is used as a feedstock material for 3D printers.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| AlSi10Mg | 15-45μm | 1KG | 70 | 15-53μm | 1KG | 51 |

| 10KG | 42 | 10KG | 33 | |||

| 100KG | 34.6 | 100KG | 23.5 |

AlSi12 Powder

AlSi12 powder is a fine-grained aluminum-silicon alloy powder commonly used in additive manufacturing processes. It is produced by atomization, which involves melting the alloy and rapidly cooling it to form small powder particles. The resulting powder exhibits excellent flowability and can be easily processed using various additive manufacturing techniques such as selective laser melting (SLM) and electron beam melting (EBM).

AlSi50 Powder

AlSi50 is an aluminum-silicon alloy powder containing 50% silicon and remainder aluminum. It offers an exceptional combination of properties like low density, high fluidity, low thermal expansion, high specific strength, and corrosion resistance.

AlSi7Mg powder

AlSi7Mg powder is an aluminum alloy powder that primarily consists of aluminum (Al), silicon (Si), and magnesium (Mg). The “7” in its name signifies the percentage of silicon, while “Mg” represents the magnesium content. This powder exhibits excellent strength, low density, and impressive thermal properties, making it a preferred choice in multiple industries.

AlSiCu Powder(AlSi10)

AlSi10 is an aluminum alloy powder containing 10% silicon and remainder aluminum. It offers an excellent combination of strength, low density, thermal properties, corrosion resistance and weldability.

AlSiMg Powder

Our company’s gas atomized AlSiMg powder, good sphericity, low oxygen content, good fluidity.at present, aluminum alloys used in metal 3D printing mainly include AlSi12 and AlSi10Mg,they are lightweight additive metal powders with good thermal properties. It can be applied to thin-wall parts such as heat exchangers and other automotive parts, and also can be applied to aerospace and aerospace industrial grade prototype and production parts.